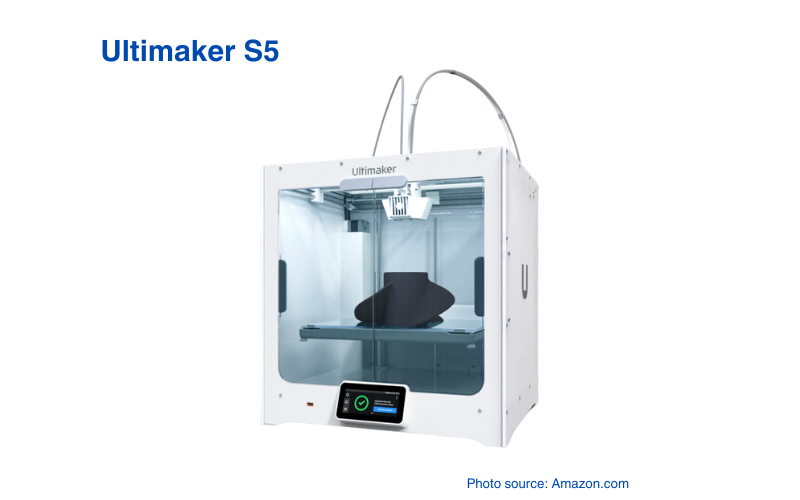

Ultimaker S5 Full Review

The Ultimaker S5 is the most popular 3D printer of the S series. It was launched in 2018 with improved features and performance from its sibling, the S3. Designed for professional 3D printing applications, it’s integrated with a suite of software tools, high-grade printing quality, and account management capabilities for a total enterprise solution. Since its introduction, the Ultimaker S5 has gained widespread adoption in various industries due to its reliability and ability to handle wide-scale and intricate projects. The combination of cutting-edge technology and user-friendly software has established the Ultimaker S5 as a preferred choice for businesses who want to refine their production capabilities and achieve top-notch results. This Ultimaker S5 full review will explore this famed 3D printer and why it’s garnered the respect and favor of the 3D printing community.

Design and Build Quality

Frame and Structure

The Ultimaker S5 is built with a high-quality but lightweight composite body. The print head is fed with the filament by the Bowder extruder. The enclosed build chamber maintains a consistent temperature. Easy monitoring of the printing process is made possible by the glass panel. The S5 comes with automatic material handling and environmental control, also known as the Ultimaker S5 Pro Bundle.

S5 Pro Bundle

The Ultimaker S5 Pro Bundle makes the standard S5 model a more powerful tool for professionals by including the Material Station and the Air Manager. The Material Station is designed to hold up to six spools of filament for an uninterrupted material feed. The Air Manager improves air quality by filtering out ultrafine particles and controlling the airflow within the build chamber. This is especially beneficial when printing with advanced materials that may emit fumes. The Pro Bundle’s enhanced material management and air quality features make it ideal for industrial applications.

Assembly Process

Setting up the Ultimaker S5 is straightforward, thanks to its well-designed assembly process. Out of the box, the printer requires minimal assembly, with most components pre-assembled. The clear instructions guide users through the setup, making the process smooth and hassle-free. Components like the print bed and extruders are easy to install. And the active bed leveling system simplifies the calibration process, making the printer ready for use quickly.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Dual Extrusion System | Build Volume: 330 x 240 x 300 mm |

| Active Bed Leveling | Print Speed: Up to 24 mm³/s |

| Filament Flow Sensor | Nozzle Diameters: 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Touchscreen Interface: 4.7-inch color display | Layer Resolutions: 0.25 mm nozzle: 150 – 60 micron; 0.4 mm nozzle: 200 – 20 micron; 0.6 mm nozzle: 300 – 20 micron; 0.8 mm nozzle: 600 – 20 micron |

| Ultimaker Cura Software | Supported Materials: PLA, ABS, Nylon, TPU, CPE, PVA, PP, PC, and more |

| Connectivity Options: Wi-Fi, Ethernet, USB | Print Head: 2 – Dual extrusion with auto-nozzle lifting system and swappable print cores |

The Ultimaker S5 has build volume of 330 x 240 x 300 mm. Its dual extrusion system accommodates multi-material prints. Active bed leveling ensures the print bed is perfectly aligned for better print quality. The filament flow sensor pauses prints when filament runs out. Connectivity options like Wi-Fi, Ethernet, and USB facilitate integration into various workflows. The 4.7-inch touchscreen interface simplifies navigation and control. Compatible with materials such as PLA, ABS, and Nylon, the S5 achieves high-resolution prints ranging from 20 to 600 microns.

Comparisons

When comparing the Ultimaker S5 to other models within the Ultimaker lineup, it is clear that the S5 offers distinct advantages in terms of features and capabilities.

Ultimaker S3

The Ultimaker S3 is ideal for users with limited space or those needing a smaller-scale production tool. While it shares features with the Ultimaker S5, there are key differences:

Build Volume: The S3 has a build volume of 230 x 190 x 200 mm. The S5’s larger build volume allows for bigger and more complex projects and intricate designs.

User Interface: The S5 is equipped with a 4.7-inch color touchscreen which makes for a more intuitive and easy-to-navigate interface. The S3, although user-friendly, uses a more traditional control system.

Filament Management: While both printers support a variety of filaments, the S5’s larger build capacity and dual extrusion system give greater flexibility in material usage.

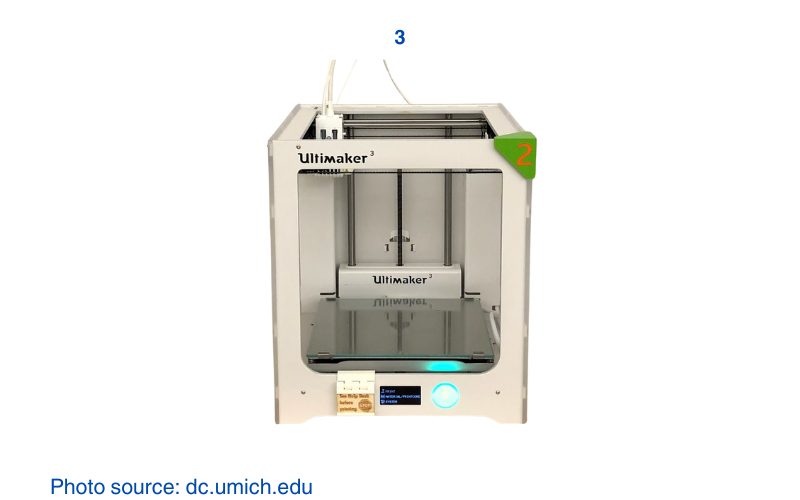

Ultimaker 3

The Ultimaker 3 is a well-regarded model known for its reliability and dual extrusion capabilities. Comparing it to the Ultimaker S5 reveals several distinctions:

User Experience: The Ultimaker 3 features a standard user interface. Whereas the S5’s 4.7-inch touchscreen gives a more advanced and user-friendly experience, simplifying navigation and control of print settings.

Advanced Features: The S5 comes with an enhanced active bed leveling system, providing more precise calibration compared to the manual leveling required by the Ultimaker 3. This ensures greater accuracy and reduces print failures.

Real World Applications

Manufacturing and Prototyping

In the manufacturing industry, the Ultimaker S5 is widely used for creating prototypes and end-use parts. Its large build volume and high precision make it ideal for developing functional prototypes. This reduces the time and cost associated with traditional manufacturing processes. Additionally, the S5’s dual extrusion system allows for the incorporation of support structures made from dissolvable materials. This enables the creation of complex geometries that would be difficult with single-material printing.

Healthcare and Medical Devices

The healthcare sector benefits greatly from the Ultimaker S5’s ability to produce highly detailed and accurate models. Medical professionals use the S5 to create anatomical models for surgical planning and patient education. These models help surgeons visualize complex procedures and improve patient outcomes. Furthermore, the S5 is used to produce custom medical devices and prosthetics tailored to individual patients, enhancing the quality of care and improving the quality of life for patients.

Architecture and Construction

In architecture and construction, the Ultimaker S5 is used to create detailed scale models of buildings and infrastructure projects. These models help architects and engineers visualize and communicate their designs to clients and stakeholders. The ability to produce accurate and intricate models enhances the planning and decision-making process, reducing errors and improving project outcomes. The S5’s capability to print with a variety of materials also allows for the creation of durable models that can withstand handling and transportation.

Automotive Industry

The automotive industry leverages the Ultimaker S5 for rapid prototyping and the production of custom parts. Engineers use the S5 to create prototypes of new components, testing their fit and function before committing to expensive tooling and manufacturing processes. The S5’s precision and reliability ensure that the prototypes closely match the final production parts. Additionally, it prints with engineering-grade materials, producing functional parts for real-world applications, such as custom fixtures and jigs.

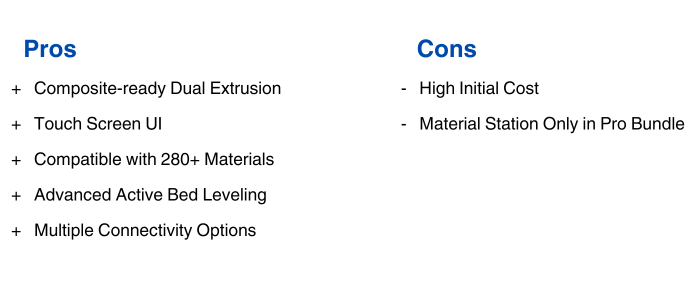

Conclusion

Since its 2018 launch, the Ultimaker S5 firmly establishes itself as a leading 3D printer in professional and industrial spheres. Its substantial build volume, dual extrusion system, active bed leveling, and intuitive touchscreen interface set it apart from other models in the Ultimaker lineup, including the S3 and Ultimaker 3. The Ultimaker S5 Pro Bundle adds the Material Station and Air Manager for improved material management and air quality control. In real-world applications, the Ultimaker S5 excels in producing high-quality prototypes, functional parts, and detailed models that meet the exacting standards of professionals across different fields. Its integration with Ultimaker Cura software ensures an optimized and streamlined printing process. The Ultimaker S5’s combination of cutting-edge technology, user-friendly design, and comprehensive feature set makes it a top choice for professionals. The Ultimaker S5 solidifies its reputation as a flagship model in the 3D printing community.

Comments are closed.