Raise3D Pro2 Full Review

Raise3D has made a name for itself in the 3D printing community by creating reliable and high-quality 3D printers that cater to professionals across various industries. Known for their innovation, Raise3D manufactures machines that are built to handle demanding projects, whether in manufacturing, healthcare, or education. The Pro2 series builds on the foundation laid by their earlier models. As an evolution of the N2 series, the Pro2 series brings several key enhancements to the table: improved performance, more advanced features, and greater versatility. The Pro2 and its larger counterpart, the Pro2 Plus, have quickly become favorites among professionals who need dependable printers that can deliver precise, high-quality results. In this Raise3D Pro2 full review, we’ll dive into the details exploring what makes it stand out and how it performs in real-world applications.

Design and Build Quality

The Pro2 is built with sturdy construction: a full metal frame and an enclosed build area. It provides a controlled environment and stability that’s ideal for printing materials that require specific temperature conditions. The overall design of the Pro2 is sleek and professional, with a clear emphasis on ease of use. The large, full-color touchscreen on the front of the machine is user-friendly and responsive. This makes it simple to navigate through settings and monitor print progress. The dual extruders are neatly integrated into the design. The build platform is heated and features a removable glass build plate. It has an automatic bed leveling system which ensures the first layer is always perfectly aligned. The Pro2’s build volume is generous, giving plenty of space for larger projects. The overall design of the printer is well thought out to support long-term, intensive use perfect for professionals.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Dual-Extrusion System | Build Volume: Single Extrusion Print: 305 × 305 × 300 mm (12 × 12 × 11.8 inch) Dual Extrusion Print: 280 × 305 × 300 mm (11 × 12 × 11.8 inch) |

| Heated Aluminum Build Plate | XYZ Step Size: 0.78125, 0.78125, 0.078125 micron |

| Automatic Bed Leveling | Layer Resolution: 10 microns |

| Filament Runout Sensor | Nozzle Diameter: 0.4 mm (Default), 0.2/ 0.6/ 0.8/ 1.0 mm (Available) |

| Power Loss Recovery | Max Nozzle Temperature: 300°C |

| Wi-Fi Connectivity | Filament Compatibility: Hyper Speed PLA/ Hyper Speed ABS/ PLA/ ABS/ ASA/ PETG/ PC/ PETG ESD/ TPU 95A/ PVA+ |

| Retractable Nozzles | Supported Filament Diameter: 1.75 mm |

| 7-inch Touch Screen Interface | Connectivity: USB, Wi-Fi, LAN, Live camera |

| HEPA Air Filtration with activated charcoal | Max Build Plate Temperature: 110ºC |

| Heated Bed Material: Silicone | |

| Print Head System: Dual-head with electronic lifting system | |

| Print Head Travel Speed: 15–150 mm/s |

The Pro2 integrates a range of advanced features that make it a powerful tool for professionals. Its dual-extrusion system allows for multi-material printing or using soluble supports, which is ideal for creating complex models. The aluminum build plate provides strong adhesion and is easy to remove. While the automatic bed leveling ensures a perfectly aligned first layer every time. The filament runout sensor and power loss recovery ensure this printer reliably prevents disruptions to your prints.

Additionally, the Pro2 supports a wide range of materials, including nylon, thanks to its high-temperature nozzles and fully enclosed build chamber. The printer’s Wi-Fi connectivity enhances its versatility by allowing remote monitoring and control. The removable build plate simplifies the process of taking off completed prints, and the retractable nozzles help prevent material contamination.

Comparisons

Raise3D Pro2 vs Raise3D E2

The Raise3D E2 is another dual-extruder model from the same company, but with a focus on compactness and affordability. Here’s how it differs from the Pro2:

Build Volume: The Pro2 has a larger build volume of 305 x 305 x 300 mm. Compared to the E2’s 330 x 240 x 240 mm, making the Pro2 more suitable for larger prints.

Extruder System: The E2 features an independent dual extrusion (IDEX) system. It allows for modes like duplication and mirror, which the Pro2 lacks. However, the Pro2’s dual extrusion system is more refined for handling complex materials.

Application: The E2 is more compact and budget-friendly, making it a better choice for educational environments or smaller workspaces. The Pro2, with its larger build volume and advanced features, is more suited for professional use.

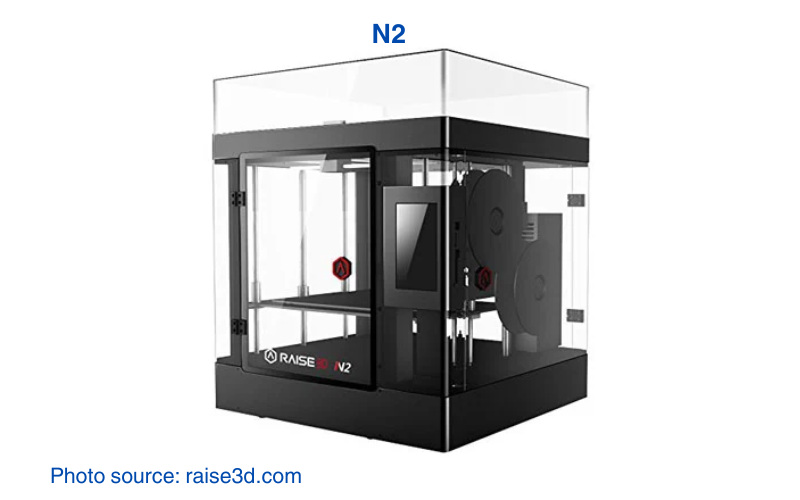

Raise3D Pro2 vs Raise3D N2

The Raise3D N2 is the predecessor to the Pro2. And while it is still a reliable machine, there are several upgrades in the Pro2:

Features: The Pro2 includes enhanced features like retractable dual nozzles, automatic bed leveling, and a filament runout sensor. These are not available on the N2.

Build Volume: Both models have similar build volumes, but the Pro2’s additional features provide a more refined printing experience.

Upgrade Consideration: The Pro2 is an ideal upgrade for those using the N2 who are looking for improved precision, convenience, and connectivity options like Wi-Fi and LAN.

Real World Applications

The Raise3D Pro2 is designed to meet the needs of a wide range of industries and applications, making it a versatile tool for professionals who require reliable and precise 3D printing capabilities.

Prototyping and Product Development

One of the most common uses for the Pro2 is in prototyping and product development. Its ability to produce highly detailed and accurate models makes it ideal for engineers and designers looking to create functional prototypes or iterate on product designs. The dual-extrusion system is particularly useful in this context, as it allows for the creation of complex parts with soluble supports, ensuring that even intricate designs can be printed with ease.

Manufacturing and Custom Tooling

The Pro2 excels in small-scale manufacturing and custom tooling. Its strong build quality and ability to handle a wide variety of materials, including more industrial-grade filaments like Nylon and ABS, make it a great option for producing durable parts and tools. The large build volume is advantageous for creating larger components or multiple smaller parts in a single print run, improving efficiency in a manufacturing setting.

Architecture and Construction

Architects and construction professionals can benefit from the Pro2’s ability to produce detailed architectural models and scale replicas of buildings and infrastructure projects. The printer’s precision allows for the accurate representation of complex geometries, while the large build volume accommodates sizable models or multiple parts of a structure.

Healthcare and Medical Devices

In the healthcare industry, the Pro2 can be used to create custom medical devices, prosthetics, and anatomical models. The ability to print with biocompatible materials and produce highly detailed models is crucial in this field. Precision and customization are often required. The Pro2’s dual-extrusion capability also allows for the printing of multi-material models, useful in creating complex medical devices.

Conclusion

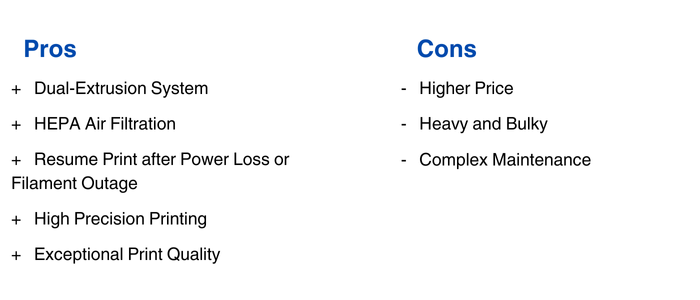

The Raise3D Pro2 is a powerhouse 3D printer. Its advanced tech specifications, dual-extrusion system, large build volume, and advanced features equip it to handle a wide range of professional applications. Its solid build quality, user-friendly interface and its ability to print with a variety of materials makes it an excellent choice for professionals across different industries. Though it comes with a higher price tag, the investment is justified by its performance and reliability in demanding environments.

In summary, the Raise3D Pro2 stands out as a highly capable and dependable 3D printer. It meets the needs of professionals across a wide range of industries. It enables users to create complex prototypes, manufacture custom parts, and explore new creative possibilities, delivering consistent, high-quality results.