Lulzbot Taz Workhorse+ Full Review

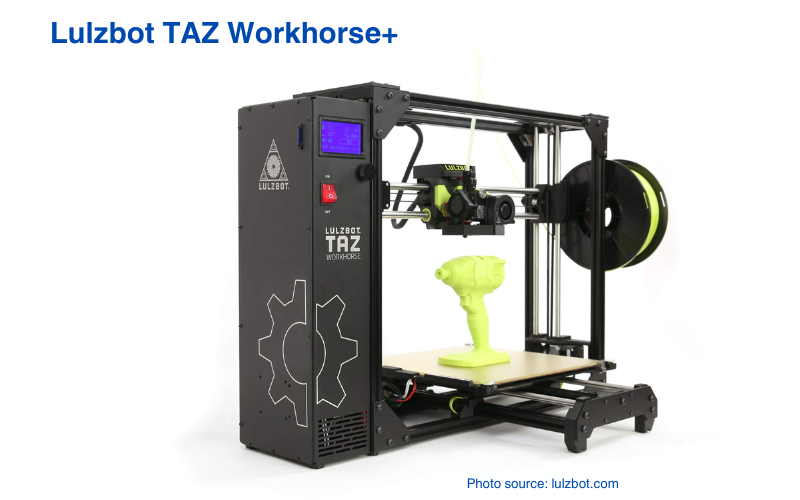

The LulzBot Taz Workhorse+ by Aleph Objects (now FAME 3D) is a 3D printer that aims to continue the legacy of its well-regarded predecessors. Known for producing reliable and open-source machines, Aleph Objects has built a solid reputation among prosumers, makers, and 3D printing professionals. Its predecessor—the Taz 6—has earned accolades as a top choice among a sea of choices in the market. With the Taz Workhorse+, they introduced several enhancements over the Taz 6, such as a bigger build volume, a reinforced frame, and a new toolhead. But it also maintained some of the familiar design elements from the Taz 6. In this Lulzbot Taz Workhorse+ full review, we will take a look at its performance, design and how it compares to its siblings in the Lulzbot line.

Design and Build Quality

Frame and Structure

The Taz Workhorse+ maintains the rugged, open-frame design that the Taz series is known for. Constructed from industrial-grade aluminum, the frame is a strong and durable structure. The open-frame design gives the printer a solid, professional appearance. It also allows for easy access to internal components, making adjustments and maintenance more convenient. The Workhorse is designed to handle the demands of continuous use with a focus on delivering consistent, high-quality prints over time.

Ease of Assembly

Aleph Objects has ensured that setting up this 3D printer is as straightforward as possible. The printer arrives with most of its components pre-assembled. This significantly reduces the time and effort required to get started. Clear, step-by-step instructions guide users through the final assembly stages.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Meteor 285 Tool Head | Build Volume: 280 x 280 x 285 mm |

| Blue Spring Steel Magnetic Flex Bed | Maximum Print Speed: 300 mm/s – Firmware Limited |

| Belt-Driven Z-Axis | Equipped Layer Height Range: 0.1mm to 0.4mm |

| Auto Bed Leveling & Cleaning | Nozzle Diameter & Material: 0.5mm Nickel Plated Brass |

| Built-In Filament Runout Sensor | Max Nozzle Temperature: 290°C |

| Open-Source | Filament Compatibility: PLA, TPU, ABS, PETg, PVA, PVB, Nylon, PC, and others below 290°C |

| Intuitive User Interface | Maximum Hot End Temperature: 295°C – Firmware Limited |

| Maximum Print Bed Temperature: 110°C | |

| Slicer Software Recommendation: Cura LE (LulzBot Edition) | |

| Frame Material: Machined Aluminum | |

| Connectivity: USB, SD Card | |

| Frame Material: Machined Aluminum |

The TAZ Workhorse+ brings several key advancements from its predecessor. The Meteor 285 Tool Head stands out with its optimized tensioning system and flexible material compatibility. The Magnetic Flex Bed ensures that parts are easy to remove after printing while maintaining a strong hold during the process. With a belt-driven Z-axis, the printer reduces common print artifacts and improves overall speed. Auto bed leveling and cleaning streamline the setup process. Some additional features are the built-in filament runout sensor and improved firmware. This model can handle materials that are more advanced and are reliable for Polycarbonate and Nylon 3D printing. The open-source nature of the TAZ Workhorse+ continues to provide users with the flexibility to customize and enhance their 3D printing workflows.

Comparison

TAZ Workhorse+ vs. TAZ 6

A comparison to consider is between the LulzBot TAZ Workhorse+ and its predecessor, the TAZ 6, which has been a popular choice among 3D printing enthusiasts for years. Here are some of the key differences:

Build Volume: The Workhorse+ offers a slightly larger build volume of 280 x 280 x 285 mm, compared to the TAZ 6’s 280 x 280 x 250 mm.

Print Bed: The TAZ 6 comes with a borosilicate glass print bed with a PEI surface, known for its durability and consistent heating. The Workhorse+, however, upgrades to a Magnetic Flex Bed, which provides a secure hold during printing and makes part removal much easier.

Tool Head: The TAZ 6 uses the Hexagon Hot End, which was effective for its time but lacks some modern advancements. The TAZ Workhorse+ features the Meteor 285 Tool Head, offering dual-drive steel gears and improved cooling.

TAZ Workhorse+ vs. TAZ Pro

One comparison worth noting is between the TAZ Workhorse+ and the TAZ Pro, a more advanced option within the same lineup. There are several key differences between them:

Build Volume: The Workhorse+ and Pro both offer substantial build volumes, but the TAZ Pro slightly edges out with its larger 285 x 285 x 285 mm build area.

Tool Head: The Workhorse+ comes equipped with the Meteor 285 Tool Head. In contrast, the TAZ Pro features a dual extruder system, which allows for multi-material printing and more intricate color or material combinations in a single print.

Price: The TAZ Workhorse+ is a more affordable option at $2,995. It’s ideal for professionals or educators who need a reliable, high-quality printer. The TAZ Pro has ahigher price point of $4,950. This is justified by its dual extrusion capabilities and larger build volume, made for professionals.

Real World Applications

Short-Run Production

The TAZ Workhorse+ can be used for producing small batches of custom parts, especially in industries like automotive and aerospace. Companies leverage its ability to print with durable materials such as nylon and carbon fiber-infused filaments. This makes it ideal for creating jigs, fixtures, and end-use components that require high strength and durability.

Product Design and Iteration

Designers and engineers can utilize the TAZ Workhorse+ for developing and iterating consumer products, including home appliances, electronics, and custom toys. Its precision and ability to produce detailed prototypes enable faster development cycles and more accurate designs, which are crucial in bringing new products to market.

Customized Tools and Parts

Farmers and agricultural equipment manufacturers can use the TAZ Workhorse+ to create custom tools, replacement parts, and modifications for machinery. This capability is especially valuable in rural areas where access to specialized parts may be limited. Which allows for on-demand production and reduced downtime for essential equipment.

Robot Parts and Components

Robotics researchers and companies working in automation can use the TAZ Workhorse+ to print custom parts for robots. This includes chassis components, gears, and housings for electronic components. The printer’s ability to handle tough materials like ABS and polycarbonate ensures that these parts can withstand the mechanical stresses encountered in robotic applications.

Conclusion

The LulzBot TAZ Workhorse+ is a reliable and versatile 3D printer, useful for professional applications. It’s applicable for custom manufacturing, product development and even specialized fields like agricultural equipment prototyping and robotics. This printer is engineered for durability, precision, and flexibility in different industries.

With its build volume, advanced Meteor 285 Tool Head, and user-friendly design, the TAZ Workhorse+ continues the legacy of the LulzBot brand. It also introduces meaningful upgrades that enhance its performance and usability. For professionals and makers looking for a 3D printer that can handle complex projects and deliver consistent, high-quality results, the LulzBot TAZ Workhorse+ is a compelling option that promises to be a valuable asset in any workshop or lab.