3D PotterBot 10 Micro Full Review

3D Potter is a company that’s built a reputation for innovative ceramic 3D printing. Founded by Steve Graber, the company introduced its first clay printer in 2014. Unlike other 3D printers, they developed their technology for real clay extrusion, working with traditional pottery materials rather than plastic or resin. This has made them popular with artists, architects, and designers who want to explore new creative possibilities with clay. Their ceramic 3D printers are known for their precision and ease of use, without needing compressed air. With their strong focus on quality and user-friendly designs, 3D Potter has become a leading name in ceramic 3D printing. In this 3D PotterBot Micro 10 full review, we’ll look at its key features, performance, and how well it handles clay printing for detailed projects.

What is the 3D PotterBot 10 Micro Ceramic 3D Printer?

The 3D PotterBot 10 Micro is a compact ceramic 3D printer built to make clay printing available for beginners. You may be an artist experimenting with clay or an educator looking for a classroom-friendly 3D printer, the 10 Micro brings high-quality ceramic printing to smaller spaces. With its user-friendly interface and affordable price, it’s a great starting point for those interested in exploring ceramic 3D printing. Despite being the smallest model in the 3D Potter lineup, the 10 Micro delivers reliable performance. It has a build envelope of up to 12 inches in height and a maximum print speed of 130mm/s. The overall construction of the printer prioritizes ease of use and durability. With food-grade materials used throughout, it is suitable for both artistic and functional ceramics, including items like kitchenware.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Direct real clay extrusion, no air compressor | Build Volume: 280 x 265 x 305 mm |

| Wireless control via full web interface | Max Print Speed: 130 mm/s (recommended 30-60 mm/s) |

| Anodized aluminum rails | Layer Resolution: Adjustable depending on nozzle size |

| 1,000ml extruder with polycarbonate tubes | Nozzle Diameter: 3mm, 4mm, 5mm, 6mm |

| Interchangeable anodized aluminum nozzles | Extruder Volume: 1,000ml |

| Compatible with full-body clay and pastes | Connectivity: WiFi, Ethernet (optional) |

| High-Precision Printing | Max Layer Thickness: Adjustable based on clay consistency |

| Food-grade materials | Feedstock Format: Paste materials (clay, etc.) |

| Materials: Ceramic, clay | |

| Operational Space: 30″ L x 22″ W x 50″ H |

The 3D PotterBot 10 Micro has a compact design that fits well in small studios or classrooms, but gives professional-level performance with a large build volume of 280 x 265 x 305 mm. With its 1,000ml extruder, users can print projects 12 inches in height. The printer’s durable anodized aluminum rails ensure smooth and precise movement during printing. Unlike other ceramic printers, the 10 Micro uses a direct extrusion system, eliminating the need for air compressors or diluted clay mixtures. This allows for the use of full-bodied clay, giving users greater control over the material and final prints.

With the built-in wireless control system, you can upload files and control the printer from multiple devices via WiFi. The interchangeable anodized nozzles, available in 3mm, 4mm, 5mm, and 6mm sizes, let users fine-tune their prints based on project requirements.

Performance and Output Quality

The 3D PotterBot 10 Micro is designed to handle both small and medium-sized ceramic creations. It combines real clay extrusion with a compact design. Let’s take a closer look at how it performs in terms of detail and consistency.

Fine Details and Smooth Surfaces

When it comes to fine details, the 3D PotterBot 10 Micro does an excellent job of capturing intricate designs. The direct extrusion system ensures that clay is applied smoothly, resulting in clean lines and smooth surfaces. Even complex shapes and textures come out well-defined with minimal post-processing. The interchangeable nozzle sizes also give users the flexibility to choose between fine details or broader strokes, depending on what the project needs.

Consistent Results with Minimal Errors

Consistency is key when working with clay, and the 10 Micro performs reliably in this area. The printer’s design minimizes common issues like clogging or uneven extrusion. The high-quality anodized aluminum rails ensure smooth movement, which further reduces the chances of mechanical errors during prints. Additionally, the 10th-generation wireless control system allows for easy adjustments, helping to maintain accuracy and reduce errors.

Comparisons

10 Micro vs. 10 Pro

The 3D PotterBot 10 Pro is a step up from the 10 Micro, offering more advanced features and greater capacity for larger projects. Here’s how the two models compare:

- Build Volume: The 10 Pro features a larger build volume of 400 x 400 x 600 mm, significantly bigger than the10 Micro’s 280 x 265 x 305 mm. 10 Pro is better suited for larger-scale ceramic prints.

- Extruder Capacity: The 10 Pro has a larger 2,000ml extruder, compared to the 10 Micro’s 1,000ml, which means fewer refills for bigger prints.

- Control System: Both models include wireless control via a full web interface, allowing for easy management from multiple devices, but the 10 Pro is optimized for more advanced use.

- Price: The 10 Pro is more expensive due to its higher build volume and professional-level features, while the 10 Micro is an affordable option for beginners or smaller-scale creators.

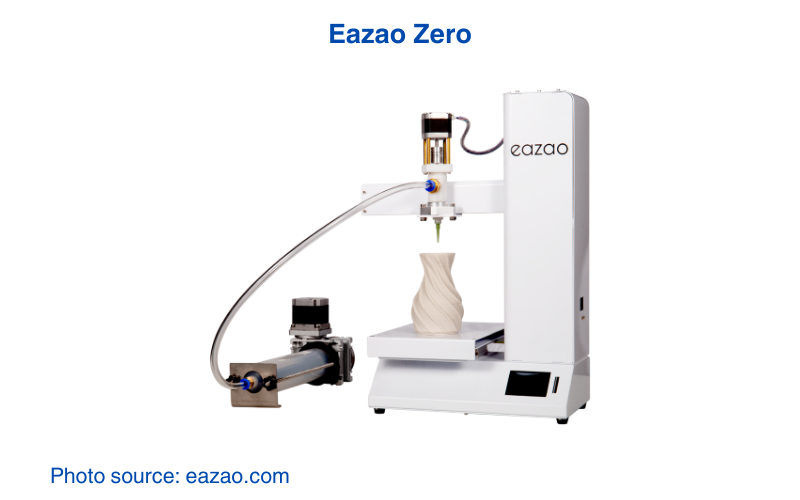

3D PotterBot Micro 10 vs. Eazao Zero

The Eazao Zero is another entry-level ceramic 3D printer for small spaces and ease of use, making it a comparable option to the 10 Micro. Here’s how the two stack up:

- Build Volume: The Eazao Zero has a slightly smaller build volume of 150 x 150 x 240 mm compared to the Micro 10’s 280 x 265 x 305 mm.

- Extrusion Technology: The Eazao Zero uses DIW (Direct Ink Writing) technology for extrusion. This is similar to the direct extrusion system in the 10 Micr. Both allow for the use of real clay and paste-like materials, but the Micro 10 supports larger extrusion volumes with its 1,000ml capacity.

- Control System: Both models offer user-friendly controls. The Eazao Zero features a touchscreen interface, while the 10 Micro includes wireless control through a web interface.

- Price: The Eazao Zero is generally priced lower, a good choice for beginners. The 10 Micro’s slightly higher price reflects its larger build volume and more advanced features.

Artistic and Practical Applications

The 10 Micro is a versatile tool across various fields. Professional creators and educational labs use this machine for both artistic and functional projects.

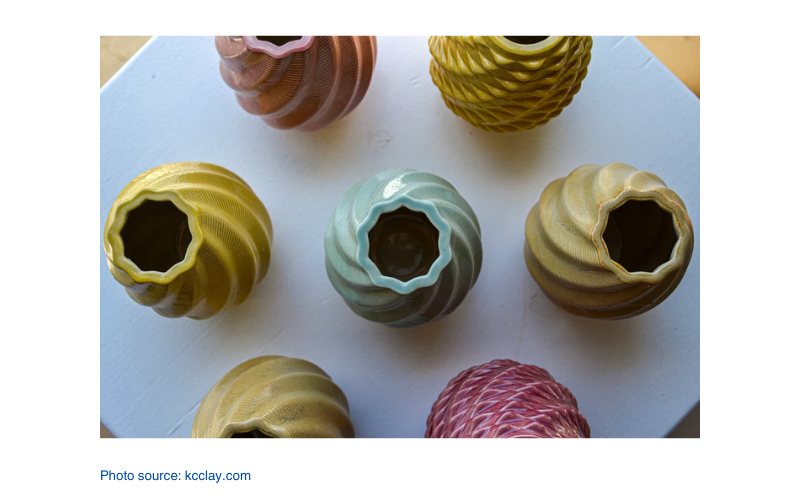

Creative Studios

In creative studios, the 10 Micro helps artists bring unique ceramic projects to life. It can be used for custom sculptures, modern ceramic art pieces and other applications. This printer’s clay extrusion system makes it easy to shape intricate designs. The ability to work with real clay allows creators to experiment with different textures and forms.

Custom Product Makers

For those producing custom items, the 10 Micro works well for small-batch creations. It’s ideal for making personalized kitchenware, home décor, or other functional ceramic pieces. With food-safe materials, the printer ensures that these items are safel for everyday use. Its compact design allows small businesses to create high-quality items without taking up too much space or requiring complex setups.

Educational Labs

In educational labs, the 10 Micro engages students with hands-on learning experiences. It introduces the principles of 3D printing while using a medium that many students are familiar with—clay. Teachers can create interactive projects that allow students to test out new ideas, experiment with ceramic techniques, and learn about the connections between art and technology. The printer’s straightforward setup makes it an accessible tool for teaching creativity and innovation.

Conclusion

The 3D PotterBot Micro 10 is a great balance of performance, ease of use, and affordability. While it doesn’t have the massive build volume or advanced features of higher-end models like the Scara V4, it delivers reliable results for small to medium ceramic projects. With its real clay extrusion system and food-grade materials, the Micro 10 is a great choice for both beginners in ceramic 3D printing.