Delta WASP 2040 Clay Full Review

WASP, or World’s Advanced Saving Project, was founded in 2012 by Massimo Moretti. The company’s roots lie in exploring how 3D printing can be used for social good. With a focus on creating solutions that address environmental concerns and benefit communities. Early on, WASP made headlines for its work in large-scale 3D printing, including projects aimed at constructing homes using local, natural materials like clay. Their goal has always been to design machines that are not only technologically advanced but also capable of making a positive impact on the world. Beyond large-scale projects, WASP has developed a broad range of 3D printers. They have desktop models and industrial machines. Their products can use materials, including plastics, ceramics, and even concrete. WASP’s machines are used across industries such as design, engineering, and architecture. This Delta WASP 2040 Clay full review will explore this ceramic 3D printer’s features, technical performance, and applications.

Delta WASP 2040 Clay Overview

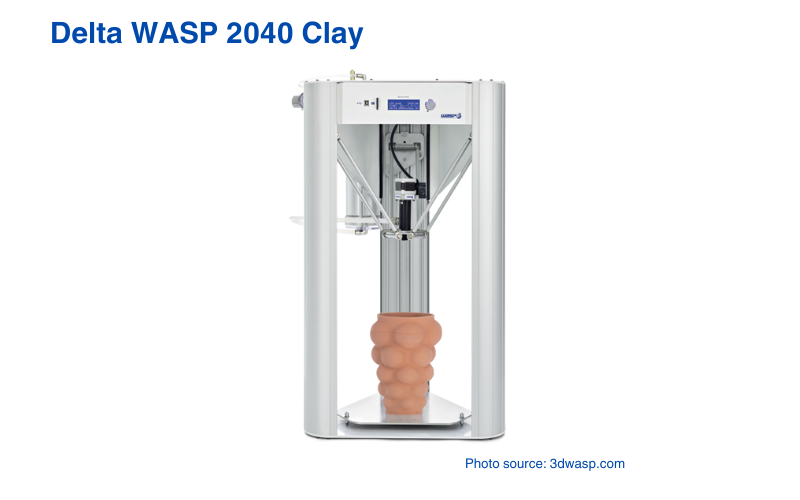

The Delta WASP 2040 Clay brings a simple, functional design with a compact form that works well in small workshops. It’s built to handle ceramic and other dense materials. Its frame combines aluminum and steel for stability to help reduce vibrations and improve the print quality. This model can print objects up to 400 mm tall, making it a great fit for those working on larger projects while maintaining a manageable size.

The open frame design gives users easy access to the print during the process. This feature comes in handy if adjustments or interaction with the object are needed without stopping the print. The print bed is made from a durable wooden multi-layer. Weighing 40 kg and measuring 44 cm x 49 cm x 87 cm, the Delta WASP 2040 Clay manages to offer a sturdy build without taking up too much space.

Delta WASP 2040 Clay’s Technology

The Delta WASP 2040 Clay is equipped with the LDM WASP Extruder 3.0, which uses a screw system to manage material flow and avoid clogs. This extruder processes materials like clay, porcelain, and earthenware. It supports different nozzle sizes, including 1.5, 2, and 3 mm, and also comes with a Luer lock adapter for finer work.

A key feature of this printer is the Resurrection System, which saves your print progress in case of power loss. Combined with the Free Z-System, the machine resumes printing right where it left off. The controlled air pressure system also ensures smooth extrusion, with an integrated air pipe connection making setup easier. It’s compatible with slicing software like Simplify3D® (official), Cura, and Slic3r, giving users flexibility. Supported file types include .stl, .obj, and .gcode. With a maximum print speed of 150 mm/s and an acceleration of 500 mm/s², this model offers fast, efficient printing for even the most detailed designs.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| LDM WASP Extruder 3.0 | Build Volume: Ø200mm x h400 mm |

| Resurrection System | Machine Dimensions: 44 cm x 49 cm x 87 cm |

| Free Z-System | Maximum Print Speed: 150 mm/s |

| Open Frame Design | Acceleration: 500 mm/s² |

| Air Pressure Control for Extrusion | Nozzle Diameter: 1.5 mm, 2 mm, 3 mm |

| Integrated Air Pipe Connection | Max Layer Height: 0.5 mm |

| Luer Lock Nozzle Adapter | Material Compatibility: Clay, Porcelain, Gres, Earthenware, and more |

| FLCD Screen with SD Card Interface |

The Delta WASP 2040 Clay comes packed with key features that make it stand out for working with ceramics and other dense materials. The LDM WASP Extruder 3.0 ensures smooth material flow, while the Resurrection System lets you recover your print after a power outage. The Free Z-System allows printing to resume exactly where it left off, saving time and materials.

With a marine multilayer wooden print bed and open-frame design, this printer provides easy access during printing. The air pressure control for extrusion ensures precision, and the integrated air pipe connection simplifies setup. It is compatible with clay, porcelain, gres, and other ceramic mixtures, making it ideal for various creative and professional projects.

Performance and Output Quality

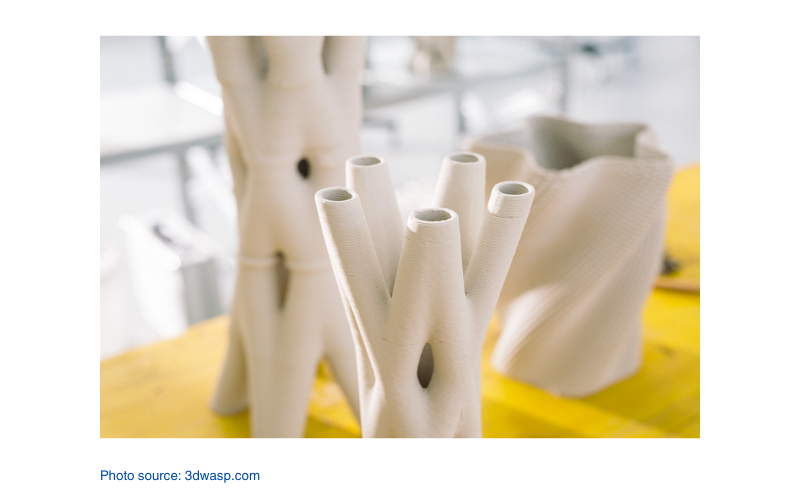

Fine Details and Smooth Surfaces

The Delta WASP 2040 Clay produces fine details and smooth surfaces when working with ceramic materials such as clay and porcelain. Thanks to its LDM WASP Extruder 3.0, the printer can manage complex designs with precision. The extruder’s ability to regulate material flow ensures that each layer is placed with accuracy. This results in smooth, seamless surfaces on printed objects. The extruder’s control over the material prevents unwanted bulges or rough patches, making it suitable for intricate designs and artistic applications. With nozzles ranging from 1.5 to 3 mm, users have the flexibility to print both detailed and larger parts. The system’s ability to handle multiple materials also adds to the quality of the prints, ensuring that surfaces remain consistent and finely detailed throughout the project.

Consistent Results with Minimal Errors

When it comes to reliability, the Delta WASP 2040 Clay delivers consistent results, even during long print sessions. The printer’s Free Z-System and Resurrection System minimize the chances of failed prints due to interruptions like power outages. These features ensure that the printer can pick up right where it left off, avoiding the need to restart a print from scratch. Additionally, the controlled air pressure system further enhances the consistency of material extrusion, reducing the risk of clogs or uneven layers. Combining this with the sturdy aluminum and steel frame that keeps vibrations low and helps maintain accuracy throughout the entire print process, makes the Delta WASP 2040 Clay a stable and precise ceramic 3D printer. Users can expect minimal errors and to consistently produce high-quality prints.

Comparisons

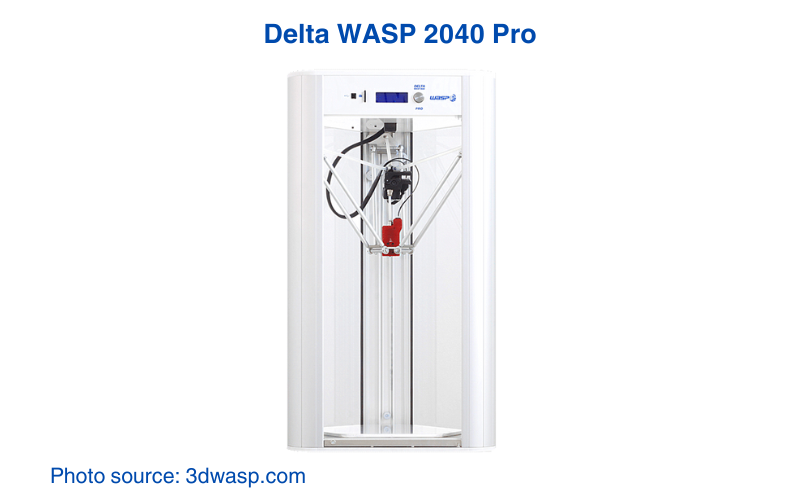

Delta WASP 2040 vs. Delta WASP 2040 Pro

When comparing the Delta WASP 2040 with the Delta WASP 2040 Pro, a few key differences may influence your decision:

- Build Volume: Both the Delta WASP 2040 and Delta WASP 2040 Pro share the same build volume of Ø200mm x 400mm. However, the Pro model includes enhancements that improve overall print performance.

- Material Compatibility: Both models work with ceramic mixtures, such as clay, porcelain, and earthenware. The Pro version, however, offers more refined material control for better handling of difficult materials.

- Features: The Delta WASP 2040 Pro has a more advanced extruder system. Which means better flow control and higher precision in dense material printing. It also supports higher print speeds and greater stability.

Delta WASP 2040 vs. 3D PotterBot 10 Micro

Another important comparison is between the Delta WASP 2040 and the 3D PotterBot 10 Micro, both designed for ceramic 3D printing:

- Build Volume: The Delta WASP 2040 Clay has a build volume of Ø200mm x 400mm. The 3D PotterBot 10 Micro has a smaller build volume. This makes the Delta WASP 2040 Clay more suitable for larger or taller projects, while the PotterBot 10 Micro is better for smaller prints.

- Material Compatibility: Both printers are optimized for working with ceramics, including clay. However, the Delta WASP 2040 Clay’s LDM WASP Extruder 3.0 has better control over material flow. The PotterBot 10 Micro, while effective for ceramics, focuses on smaller-scale prints and may not have the same level of precision for larger jobs.

- Advanced Features: The Delta WASP 2040 Clay comes equipped with advanced features like the Resurrection System and Free Z-System. The PotterBot 10 Micro lacks these features, making the Delta WASP 2040 a more reliable option for projects that require continuous printing over long periods.

Useful Applications

Architectural Model Making

The Delta WASP 2040 Clay can be a tool for architects who need to create detailed, large-scale models of structures. Its ability to print tall, accurate components with ceramic materials like clay and porcelain makes it a great choice for creating realistic building facades or intricate architectural elements. For instance, architects can use the printer to craft miniature versions of brick walls, columns, or even entire sections of a building that can demonstrate texture and structure.

Custom Product Makers

For custom product makers, the Delta WASP 2040 Clay is an excellent choice for small-batch production of personalized items. You can create customized home décor, one-of-a-kind kitchenware, or functional ceramic pieces. The printer is versatile and precise to ensure that each item meets high-quality standards.

Creative Studios

In creative studios, the Delta WASP 2040 Clay allows artists to craft unique and intricate ceramic projects. Its precise clay extrusion system makes it possible to shape custom sculptures, detailed pottery, and other artistic creations. Because it has the ability to work with various ceramic materials like clay and porcelain, this printer gives creators the freedom to experiment with different textures and forms.

Conclusion

The Delta WASP 2040 Clay is a solid all-around ceramic 3D printer. Whether you’re an artist experimenting with clay or a professional looking for high-quality prototypes, this printer has what you need. Its ability to handle detailed designs, work with various materials, and recover from power interruptions makes it reliable. It’s compact enough to fit in most workspaces, but powerful enough to handle the demands of more complex projects. If you’re looking for a dependable ceramic 3D printer that balances precision and ease of use, the Delta WASP 2040 Clay is worth considering.