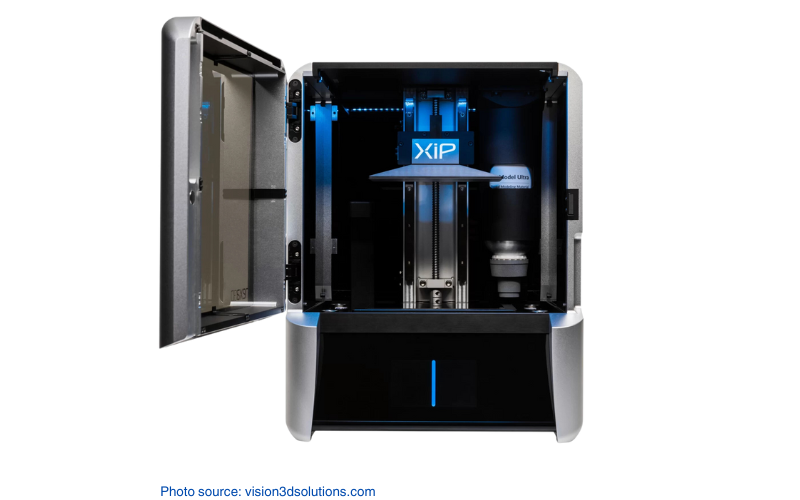

Nexa3D XiP Review

Nexa3D pushes the limits of 3D printing technology by developing some of the fastest polymer printers available today. The company’s innovative technologies, like Lubricant Sublayer Photo-curing (LSPc) and Quantum Laser Sintering (QLS), drive high-speed production for both photoplastics and thermoplastics. By partnering with industry leaders, Nexa3D continually expands their range of high-performance materials. Their commitment to sustainability includes reducing waste, cutting energy use, and supporting global reforestation efforts through ForestNation. Resin 3D printing has reshaped manufacturing by enabling high-quality prints through UV-curable liquid resins. This method is popular for its ability to produce smooth surfaces and capture fine features, making it useful for industries like healthcare, product development, and custom production. In this review, we explore the Nexa3D XiP, covering its features, performance capabilities, and practical uses. Let’s take a look at how the XiP redefines desktop resin 3D printing with speed, efficiency, and ease of use.

Design and Build Quality

The Nexa3D XiP features a compact design built for durability and ease of use. Its sturdy aluminum frame keeps it stable while fitting comfortably on a desktop. The modular design simplifies maintenance, making part replacements straightforward. With dimensions of 420mm (16.5”) W x 350mm (14”) D x 530mm (21”) H, the XiP packs an impressive 4.8-liter build volume into a manageable size. Its Z-axis setup uses parallel linear rails and a recirculating ballscrew for steady, consistent printing. The 5.5-inch color OLED touchscreen keeps controls clear and easy to navigate. Built for frequent use, the Nexa3D XiP brings professional-grade resin printing to a desktop format without complicated setups.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 4K Mono LCD | Build Volume: 195 x 115 x 210 mm (4.8L capacity) |

| LSPc Technology | Resolution: 50 µm, 100 µm, 200 µm layer thickness options |

| Everlast-2 Membrane | Light Engine: 405 nm LED array with collimating lens |

| Open Material Platform | Display: 5.5-inch color HD OLED touchscreen |

| Quick-Change Resin System | LCD Resolution: 14K (13320×5120) |

| Built-In Spill Containment | Resin System: Auto-feed with smart NFC bottle recognition |

| Versatile Connectivity | Hardware: Aluminum frame with linear rails and a recirculating ballscrew Z-axis |

| Supported Software: NexaX 2.3 Basic or Pro, supports .stl and .obj files |

The Nexa3D XiP combines speed, practicality, and convenience for modern 3D printing tasks. Its 4K monochrome LCD with a 9.3-inch display delivers sharp, consistent results. Powered by Lubricant Sublayer Photo-curing (LSPc) technology, the XiP prints at speeds of up to 18 cm per hour, reducing project completion time. Its open material platform supports a broad selection of third-party resins, giving users flexibility for different applications.

The Everlast-2 membrane boosts durability, ensuring long-lasting print performance. Its modular structure simplifies upkeep, while the automatic resin system makes material changes quick and hassle-free. Built-in spill containment keeps the workspace clean, and connectivity through Ethernet, USB, and Wi-Fi streamlines printer management. This well-thought-out design supports efficiency without complicating the printing process.

Comparisons

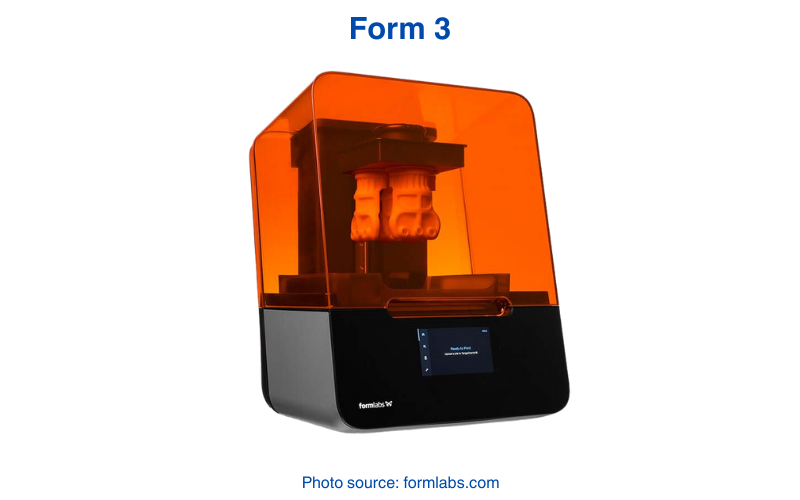

Nexa3D XiP vs. Formlabs Form 3

The Nexa3D XiP and Formlabs Form 3 are made for different types of resin 3D printing users, focusing on speed, flexibility, and advanced features.

- Ease of Use: The XiP features a quick-change resin system and an intuitive 5.5-inch OLED touchscreen, simplifying printer management. The Form 3 has automated resin dispensing but lacks the open material platform of the XiP, limiting resin choices to Formlabs’ proprietary materials.

- Printing Speed: The XiP’s LSPc technology delivers print speeds of up to 18 cm per hour, making it significantly faster than the Form 3. It prints at a slower pace due to its Low Force Stereolithography (LFS) process.

- Material Compatibility: The XiP’s open material platform supports a variety of third-party resins, giving users greater flexibility. The Form 3 is restricted to Formlabs-certified resins, limiting material choices.

- Maintenance and Durability: The XiP’s modular design simplifies maintenance, with easily replaceable components like the Everlast-2 membrane. The Form 3 has a sealed design, making part replacement more complex and service-dependent.

Nexa3D XiP vs. Anycubic Photon Mono X

The Nexa3D XiP and Anycubic Photon Mono X serve different market segments, balancing performance and accessibility.

- Build Volume: The XiP has a larger build volume of 195 x 115 x 210 mm, giving more space for complex models. The Mono X has a slightly smaller build area, better suited for standard-sized prints.

- Print Speed: With its LSPc technology, the XiP outpaces the Mono X in speed, reaching up to 18 cm per hour, while the Mono X operates at a slower rate typical of traditional LCD-based printers.

- User-Friendly Features: The XiP includes features like an auto-feed resin system and spill containment for easier maintenance. The Mono X requires manual resin management and lacks built-in spill protection.

- Connectivity: The XiP comes with Ethernet, USB, and Wi-Fi connectivity for better remote management. The Mono X primarily uses USB, limiting its control options.

Real-World Applications

The Nexa3D XiP serves a variety of industries, presenting rapid prototyping and production capabilities. Here are some examples:

- Product Development and Prototyping: Nexa3D collaborated with Xometry to expedite the development of the XiP printer itself. By utilizing Xometry’s on-demand manufacturing services, Nexa3D sourced critical components efficiently, reducing the lead time from concept to market to just 18 months.

- Dental and Medical Models: Keystone Industries adopted Nexa3D’s NXD 200 printer to enhance dental model production. The large build volume and high speed enabled Keystone to print 32-36 full-arch splints in 76 minutes, significantly increasing throughput for busy dental labs.

- Jewelry and Artisanal Crafts: While specific case studies in jewelry are not detailed, the XiP’s high-resolution printing and compatibility with various resins make it suitable for creating intricate jewelry designs and artisanal pieces.

- Manufacturing and Small Batch Production: Innotech Marine utilized the XiP printer and Freeform Injection Molding to produce durable, waterproof prototypes. This approach reduced costs and accelerated time-to-market in the marine industry.

Conclusion

The Nexa3D XiP delivers fast and efficient resin printing with a smart design built for productivity. Its LSPc technology pushes print speeds up to 18 cm per hour, saving time on every project. The large build volume and advanced UV light engine produce consistent prints across various applications, from product prototypes to dental models and custom jewelry.

With an open material platform, the XiP works with a wide selection of resins, offering flexibility for different tasks. Its modular structure simplifies maintenance, while features like automatic resin management and spill containment reduce manual work and cleanup. The XiP combines speed, durability, and convenience, making it an excellent choice for businesses and professionals ready to take their resin printing to the next level.