Best Polycarbonate 3D Printers on a Budget

Polycarbonate (PC) is one of the toughest materials you can use in 3D printing. It’s strong, impact-resistant, and can handle high temperatures, making it a go-to choice for engineers, manufacturers, and hobbyists who need parts that won’t crack under pressure. But while polycarbonate prints are incredibly durable, working with this filament isn’t as simple as loading a spool and hitting “print.” It needs high extrusion temperatures, proper bed adhesion, and a controlled environment to prevent warping or layer separation. In this article, we’ll break down what makes polycarbonate special, what challenges you might face when printing it, and our picks for the best polycarbonate 3D printers if you’re on a budget.

Why 3D Print With Polycarbonate?

Polycarbonate is used in headlight covers, safety goggles, and even bulletproof glass. That’s because it’s insanely tough—about 250 times more impact-resistant than glass—while still being lightweight and clear. The combination of strength, durability, and transparency is ideal for 3D printing. It’s especially great for functional parts that need to handle stress, heat, or even some level of flexibility.

Polycarbonate is also widely used in engineering and manufacturing because it’s highly recyclable and easy to work with once you understand how to print it properly. But here’s the catch: polycarbonate isn’t the easiest material to print. It requires a high-temperature hot end, a heated bed, and an enclosed chamber to control warping and maintain strong layer adhesion. It also absorbs moisture from the air, which can lead to print failures if you don’t keep it dry.

So, is it worth the effort? Absolutely—if you’re willing to dial in your settings and use the right equipment. Let’s break down why polycarbonate is such a powerful 3D printing material, what challenges to expect, and how to get the best results.

What Makes Polycarbonate a Great 3D Printing Material?

Polycarbonate is one of the strongest materials you can print with. Here’s why it’s unique:

- Extreme Impact Resistance – PC is stronger than ABS and PLA. It’s perfect for parts that take a beating, like drone frames, tool holders, or protective casings.

- High Heat Resistance – Unlike PLA, which softens at around 60°C, PC holds its shape up to 135°C, so it’s ideal for parts exposed to heat.

- Transparency and Optical Clarity – PC is naturally clear and can be used for things like prototype windows, light covers, or see-through enclosures.

- Good Flexibility – It’s more flexible than PLA or ABS but still rigid enough for strong, durable prints.

- Electrical Insulation – PC doesn’t conduct electricity, so it’s often used for electronic housings or insulating parts.

- Chemical Resistance – It holds up well against oils, greases, and some acids, making it useful for industrial applications.

Challenges of Printing with Polycarbonate

Printing polycarbonate isn’t as easy as PLA or even ABS. It has a few quirks that can make or break your print:

1. High Printing Temperature

Polycarbonate requires a nozzle temperature of at least 280°C, with many brands recommending 290–300°C. If your printer can’t reach these temperatures, PC isn’t going to work.

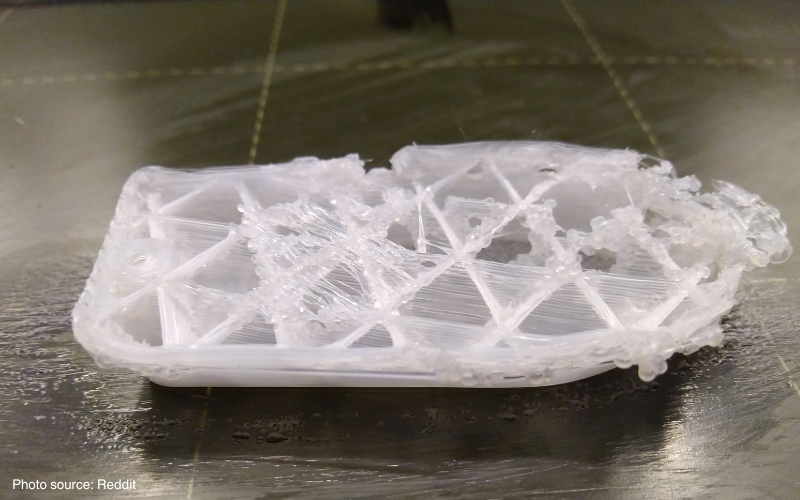

2. Warping and Shrinkage

PC shrinks as it cools, which can lead to warped or cracked prints. An enclosed chamber is highly recommended to keep the temperature consistent and reduce warping.

3. Poor Bed Adhesion

Because it shrinks as it cools, PC can pull away from the print bed, causing failed prints. A heated bed set between 110–150°C helps, and using a strong adhesive like PEI sheets, glue stick, or specialized adhesives can improve bed adhesion.

4. Moisture Absorption

PC is hygroscopic, meaning it absorbs moisture from the air. If the filament isn’t stored properly, you’ll get bubbly, weak prints. Always keep PC filament in a sealed container with desiccant or a filament dryer.

5. Strong Fumes and Odors

Printing PC releases strong fumes, so it’s best to print in a well-ventilated area or use an enclosure with a HEPA filter.

How to Get the Best Prints with Polycarbonate

If you’re set on printing with PC, here’s how to get strong, successful prints:

✅ Use the Right Printer – You’ll need a high-temp hot end (up to 300°C), a heated bed (110–150°C), and an enclosed chamber to prevent warping.

✅ Keep Your Filament Dry – Store your PC filament in a sealed, dry box or use a filament dryer before printing.

✅ Slow Down Your Prints – Printing PC too fast can cause poor layer adhesion. Start with 30–50mm/s and adjust as needed.

✅ Turn Off Part Cooling – PC doesn’t like cooling fans. Turn off part cooling or keep it very low to maintain strong layer bonding.

✅ Use an Adhesion Helper – Print on a PEI sheet, Kapton tape, glue stick, or Magigoo PC to help the first layer stick.

✅ Tune Retraction Settings – PC is prone to stringing and oozing, so set retraction carefully (start around 3–5mm and adjust).

Here are our pick for the best polycarbonate 3D printers on a budget:

Because polycarbonate is a difficult material, it also needs advanced capabilities in order to print it effectively and not waste it. 3D printers that can handle to print this material are often at a premium price range, but there are some machines that can be affordable for hobbyists:

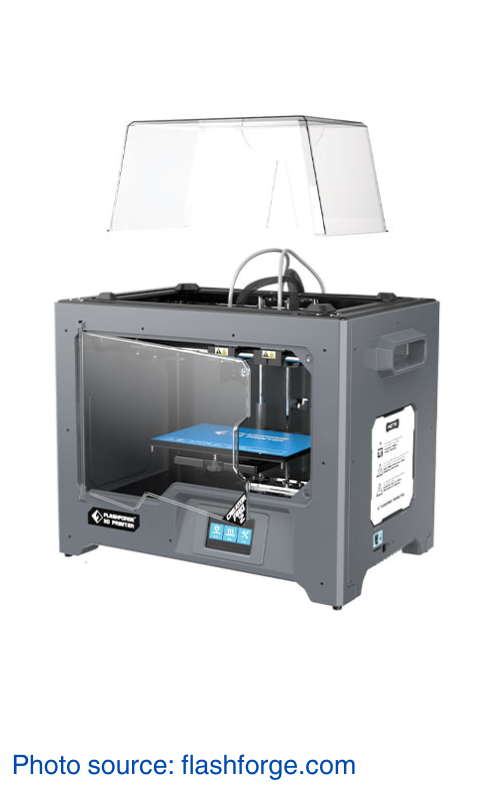

Flashforge Creator Pro 2

The Flashforge Creator Pro 2 is a solid choice if you’re looking for a budget-friendly enclosed 3D printer that can handle PC blends like PC-ABS. It’s got dual independent extruders (IDEX), meaning you can print with two different materials at the same time or use dissolvable supports for cleaner prints.

Why It Works for Polycarbonate

✅ Enclosed Chamber – Keeps the heat in, reducing warping and layer separation.

✅ Heated Bed (Up to 120°C) – Helps PC stick to the bed better, preventing curling.

✅ Direct Drive Extruder – Better control over filament, reducing jams and stringing.

✅ Dual Extrusion (IDEX System) – Lets you print with two materials at once or use breakaway supports.

What to Keep in Mind

⚠️ Hot End Maxes Out at 240°C – That’s low for pure PC, but works for PC-ABS blends.

⚠️ Cooling Fan Control Needed – PC doesn’t like too much airflow, so you’ll need to tweak the fan settings.

Who Should Get It?

If you’re on a budget and need a reliable enclosed printer for PC-ABS or other mid-temp materials, this is a great pick. But for pure PC, you’ll need something with a hotter nozzle.

QIDI Plus 4

The QIDI Plus 4 is a beast of a printer when it comes to handling high-temp materials like pure polycarbonate. It’s a CoreXY machine, which means it moves fast and smooth, and it’s got a fully enclosed, heated chamber to keep prints from warping. If you’re serious about printing strong, heat-resistant parts, this one’s worth checking out.

Why It Works for Polycarbonate

✅ Hot End Reaches 300°C – Perfect for pure PC, ensuring solid layer bonding.

✅ Enclosed & Heated Chamber – Keeps the print environment stable, preventing cracks and warping.

✅ Heated Bed (Up to 120°C) – Helps the first layer stick better.

✅ CoreXY Motion System – Faster and more precise than standard setups.

✅ Dual Extruder Setup – Lets you print with support materials like breakaway or soluble filaments for cleaner prints.

What to Keep in Mind

⚠️ More Advanced Settings – You’ll need to fine-tune print temps and speeds to get the best PC results.

⚠️ Filament Needs to Be Dry – PC absorbs moisture fast, so using a filament dryer before printing is a must.

Who Should Get It?

If you want a fast, reliable, and high-performance 3D printer that can handle pure PC like a pro, the QIDI Plus 4 is a fantastic choice. It’s great for anyone who needs strong, heat-resistant parts without constantly fighting warping issues.

Final Thoughts

Printing with polycarbonate isn’t the easiest, but if you need strong, heat-resistant, and impact-resistant parts, it’s one of the best materials out there. Whether you’re making functional prototypes, machine parts, or rugged enclosures, PC delivers durability that most other filaments just can’t match.

That said, you need the right setup to make it work. A high-temp hot end (at least 280°C), a heated bed (110°C or more), and an enclosed chamber are all must-haves. You’ll also need to keep your filament dry and fine-tune your print settings to get solid, reliable results.

If you’re using a printer like the Flashforge Creator Pro 2, you’ll be able to print PC-ABS blends, which give you a good balance of strength and printability. But if you want to go all-in with pure polycarbonate, something like the QIDI Plus 4, with its 300°C hot end and enclosed heated chamber, is the way to go.

At the end of the day, polycarbonate is worth the effort if you need parts that can handle serious heat, stress, and impact. If you’re willing to dial in your settings and use the right printer, you’ll get some of the toughest, most reliable prints possible.