Anycubic Kobra 3 Max Combo

Large-format 3D printing opens up possibilities that just aren’t feasible with smaller printers. Instead of being limited to standard projects. You can print large prototypes, full-scale models, and even functional parts—all in one piece. These printers aren’t just bigger; they’re built to handle longer print jobs and larger material loads while maintaining consistent performance.

In terms of size, small printers have build volumes around 180 mm³—fine for quick, smaller projects. Standard printers handle 250 mm³, which works well for general use. Mid-sized printers jump to 300 mm³, giving you more room to experiment with larger designs. Once you hit 400 mm³, you’re in large-format territory, with extra-large printers reaching 500 mm³ and giant machines going beyond 600 mm³ for massive builds.

Bigger builds come with their own challenges, like keeping the bed temperature even and making sure prints stay adhered to the surface. Plus, these machines take up more space and can run louder during long prints.

Manufacturers, such as Anycubic, have designed larger 3D printers with smarter features. These include functions like auto-leveling, reinforced frames, and extruders capable of handling tougher materials. In this review, we’ll take a closer look at the Anycubic Kobra 3 Max Combo, a large-format 3D printer designed for big projects. We’ll go over its design, standout features, and how it handles real-world use to help you decide if it’s the right fit for your workspace.

Design and Build Quality

The Anycubic Kobra 3 Max Combo is built for large-scale projects, and you can tell right away by its sturdy aluminum frame. It’s strong enough to handle the weight and size of bigger prints without shaking or losing stability. Because of the open-frame design, prints are easy to access and work with. For a machine this big, having a stable frame is key to getting good results.

With a build volume of 420 x 420 x 500 mm, there’s plenty of room for large prints. The print bed has a textured surface to help keep prints in place, especially during long prints that run at higher temperatures. The heated bed also helps prevent warping—something that can be a real issue with bigger prints, especially if you’re using filaments that tend to curl at the edges.

The direct drive extruder does a great job of feeding filament smoothly. This helps a lot if you’re working with flexible or more challenging materials. The wiring is neat, and the touchscreen interface is simple to use, so adjusting settings or starting a new print is not a struggle. Despite its size, the setup and design isn’t overly complicated.

Speaking of setup, the Kobra 3 Max Combo comes mostly pre-assembled. You only need to attach a few parts, and then you’re good to go. For a large-format printer, the quick setup is a nice surprise—it’s straightforward enough that even if you’re new to bigger printers, you won’t feel overwhelmed.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Large Build Volume | Build Volume: 420 x 420 x 500 mm³ |

| LeviQ3.0 Auto-leveling, Z-Offset | Print Speed: Recommended 300 mm/s; max 600 mm/s |

| ACE PRO Flawless 8-Color Printing | Nozzle Temperature: Up to 300°C |

| Automatic Leveling and Motor Anti-Skip | Hotbed Temperature: Up to 90°C (heats up in 125 seconds) |

| Filament Drying Box | Extruder Type: Direct drive |

| Quick Relase Hotend | Filament Compatibility: PLA, PETG, TPU (best performance), ABS, ASA (capable)r |

| Easy to Use Interface | Build Platform: PEI spring steel plate |

| Connectivity: Wi-Fi, LAN, AC Cloud, USB | |

Kobra 3 Max Combo

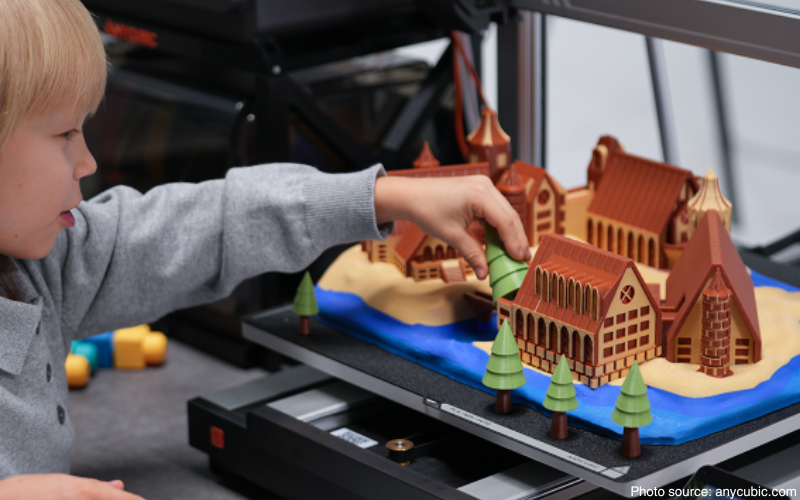

The Anycubic Kobra 3 Max Combo is designed for big, ambitious prints with a massive 420 x 420 x 500 mm build volume—roughly the size of two carry-on suitcases. This means you can print large models in one shot instead of piecing smaller sections together. With the ACE Pro system, you can take things even further, printing with up to 8 different colors in a single job without manual filament swaps.

Its direct drive extruder is built to handle flexible and high-temperature filaments, thanks to a 300°C aerospace-grade hotend. The LeviQ 3.0 auto-leveling system handles bed calibration automatically and even adjusts the Z-axis for perfect first layers. Dual motors on the Y-axis and SG15 bearings keep everything aligned during fast prints, so you get clean layers even at speeds of up to 600 mm/s.

The printer’s PEI-coated steel build plate grips prints tightly to prevent warping but releases them easily when the job’s done. A filament drying box helps keep materials in good condition, preventing clogs and weak prints caused by moisture. Plus, the AI monitoring system can detect spaghetti-like print failures and pause the job before things get out of hand.

With Wi-Fi, LAN, and app control, you can manage and monitor your prints remotely, even capturing time-lapse footage of your progress. It’s a printer built for creators who want speed, space, and smart features all in one machine.

Comparisons

Anycubic Kobra 3 Max Combo vs. Elegoo Neptune 4 Max

The Neptune 4 Max is a close match in size and speed but doesn’t have the same range of features as the Kobra 3 Max Combo.

- Extruder System: Both printers have direct drive extruders, but the Kobra’s 300°C hotend supports a wider range of filaments.

- Build Volume: Both printers have a 420 x 420 mm build area. But the Kobra’s 500 mm height beats the Neptune’s 480 mm.

- Auto-Leveling: The Kobra 3 Max Combo’s LeviQ 3.0 system includes Z-offset adjustments and belt tensioning, while the Neptune’s system handles basic leveling but lacks extra tuning options.

- Printing Speed: The Kobra 3 Max Combo reaches 600 mm/s, while the Neptune 4 Max runs up to 500 mm/s.

- Extra Features: The Kobra 3 Max Combo has a filament drying box to prevent moisture issues and AI print monitoring to catch failures mid-print. The Neptune 4 Max focuses on quiet operation but doesn’t have these extra safeguards.

Anycubic Kobra 3 Max Combo vs. Prusa XL

The Prusa XL is known for its tool-changing system. On the other hand, Kobra 3 Max Combo keeps things simple while still handling multi-color prints.

- Extruder System: The Prusa XL can load up to 5 toolheads for multi-material printing. The Kobra 3 Max Combo uses its ACE Pro system to handle up to 8 colors with a single nozzle.

- Build Volume: The Kobra 3 Max Combo’s 420 x 420 x 500 mm build area is taller than the Prusa XL’s 360 x 360 x 360 mm space.

- Auto-Leveling: Both printers have auto-leveling, but the Kobra 3 Max Combo includes Z-offset adjustments and belt tensioning for more consistent layers.

- Printing Speed: The Kobra 3 Max Combo reaches up to 600 mm/s, while the Prusa XL focuses more on slower, detailed prints.

- Connectivity: The Kobra 3 Max Combo supports Wi-Fi, LAN, and app control. The Prusa XL also supports remote control but is more focused on precision than ease of control.

Real World Applications

The Anycubic Kobra 3 Max Combo is built for projects that need more space, speed, and creative control. Here’s where it performs best:

- Multi-Color Product Prototypes: Creating detailed, multi-color prototypes is simple with the ACE Pro system. You can print up to 8 colors in one go, skipping the hassle of filament swaps or piecing parts together. This makes it perfect for product mockups or promotional displays.

- Large-Scale Furniture Parts: The 420 x 420 x 500 mm build volume makes full-sized furniture components easy to print. You can create chair legs, table joints, or decorative panels in one piece. The filament drying box also keeps materials dry, which helps prevent weak spots in large prints.

- Industrial Molds and Jigs: This printer is great for making large molds and jigs for production. Its 600 mm/s speed and quick-heating hotbed cut down print times, even for big, complex jobs. The PEI-coated plate keeps prints steady, preventing mid-job shifts.

- Automotive Parts and Custom Mods: Need a custom dashboard or decorative trim? The Kobra 3 Max Combo can handle large car parts with ease. The 300°C hotend supports tough filaments for durable prints, and multi-color support adds a creative touch for interior mods.

- Large Art Pieces and Installations: Artists can print large sculptures and interactive pieces in one shot. The ACE Pro’s multi-color capability helps bring bold designs to life without the need for post-processing.

Final Notes

The Anycubic Kobra 3 Max Combo is built for big ideas, with a massive 420 x 420 x 500 mm build volume, fast speeds, and smart features that make large-scale printing easier. Its direct drive extruder, 300°C hotend, and PEI-coated build plate handle both flexible and durable filaments without trouble.

What really sets it apart is the ACE Pro system, which lets you print up to 8 colors in one job without the hassle of swapping filaments. The LeviQ 3.0 auto-leveling and AI monitoring help keep prints on track, even during long runs. The built-in filament drying box adds an extra layer of reliability, keeping moisture-related issues at bay.

If you need a printer that can handle multi-color prototypes, oversized parts, or creative displays, the Kobra 3 Max Combo has you covered. Its combination of size, speed, and convenience makes it a solid choice for anyone ready to take on ambitious 3D printing projects.