Anycubic Kobra 3 Review

Anycubic was established in 2015 in Shenzhen, China, with the aim of bringing 3D printing technology to a broader audience. The company gained early recognition for its affordable desktop printers, which appealed to creators and makers. Their first major success came with the release of the Anycubic i3 Mega, an FDM printer known for its durability and simple assembly process. This model helped establish Anycubic’s place in the market.

Over the years, Anycubic expanded its product range to include the Photon series. It’s one of the most widely used lines of consumer-grade resin 3D printers. The introduction of the Photon Mono series in 2020 marked a significant shift toward faster print speeds and improved UV matrix lighting. Meanwhile, the Kobra series was designed for those who prefer filament-based printing with automated leveling features and larger build capacities.

In this article, we’ll take an in-depth look at the Anycubic Kobra 3. We’ll cover its design, performance, and key features to help you understand how it fits into Anycubic’s growing lineup of 3D printers.

Design and Build Quality

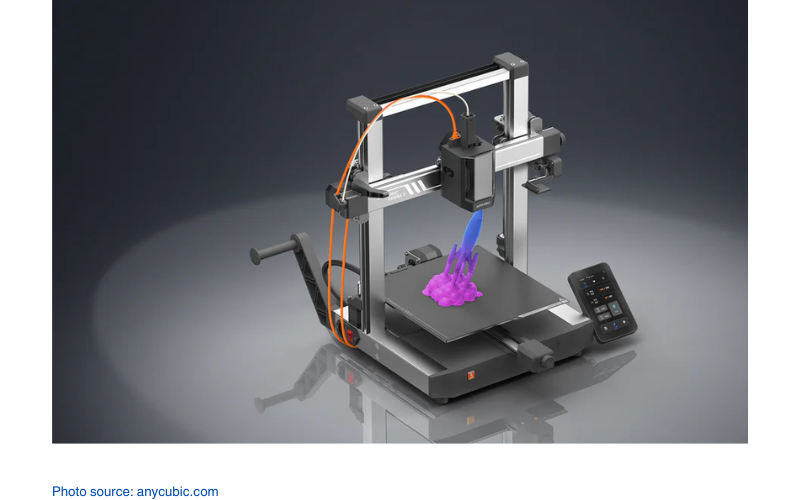

The Kobra 3 sticks to a familiar FDM 3D printer structure, but there are some notable tweaks that give it a more refined build. The stability from the double metal spindles on the Z-axis and the SG15 bearings becomes more apparent when pushing the printer to higher speeds. However, the real change is in the modular setup—there’s less cable clutter. The unified design for the key components makes maintenance less of a hassle.

At first glance, it doesn’t scream anything groundbreaking, but its 452.9mm by 504.7mm build feels appropriate for the 250mm x 250mm x 260mm print volume it supports. It’s a noticeable 34% increase compared to earlier models in Anycubic’s lineup. The build platform uses a PEI-coated spring steel sheet. This improves adhesion and makes it easier to remove finished parts once they cool..

One of the standout physical elements is the tilting 4.3-inch touchscreen, which adjusts between 30° and 60°. While this feature doesn’t necessarily improve printing performance, it does make interacting with the machine more comfortable, especially if your setup isn’t at eye level.

The overall build gives the impression that Anycubic focused on practical improvements rather than flashy additions. While that’s generally a good approach, some users may wish for more polish in the finish. Anycubic’s structural choices seem aimed at supporting high-speed operation reliably.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| High-Speed Printing | Build volume: 250*250*260mm |

| Auto-Leveling with LeviQ 3.0 | Printing speed: up to 600mm/s |

| Filament Flow Control | Nozzle: ≤300℃ |

| Built-In Vibration Compensation | Extruder: Single, hardened steel extruder gear |

| Hotend Module with Quick Swap | Hotbed Temperature: ≤110℃ |

| 4.3-inch User-Friendly Touchscreen | Slicer Software: AnycubicSlicer/AnycubicSlicer for Orca |

| 32-bit Motherboard and Silent Drivers | Material: Kobra 3 only: supports PLA, PETG and TPU. ACE PRO only: supports PLA, PETG, ABS, ASA, PET, PA, PC, PP, HIPS. |

| Filament Runout Detection and Auto Resume | Connectivity: USB flash drive, Wi-Fi, AC Cloud |

The Kobra 3 pulls together features for speed and convenience. It has the ability to print at speeds up to 600 mm/s, with acceleration reaching 20,000 mm/s². In real-world terms, this means you can complete a 3D Benchy print in just over 11 minutes. And it’s a noticeable 34% increase compared to earlier models in Anycubic’s lineup.

One of the standout inclusions is the LeviQ 3.0 automatic bed-leveling system. Instead of the usual guesswork with paper shims, the Kobra 3 calibrates the print bed and adjusts the Z-offset on its own. The smart flow control system also does its part by regulating nozzle pressure to keep extrusion steady. Since fast printing often leads to ringing artifacts on corners, the built-in vibration compensation system steps in to help smooth things out by adjusting the printer’s motion in real time. The hotend module supports tool-free swaps and can hit temperatures up to 300°C, meaning you can print with PLA, PETG, and TPU, although higher-temperature materials like ABS aren’t supported here.

Noise levels are kept in check thanks to the 32-bit motherboard and silent stepper drivers. This help make the printer quieter during operation. The filament runout detection and auto-resume function come in handy for long prints, as they let you pick up where you left off if the power cuts out or the filament runs dry.

Comparisons

Anycubic Kobra 3 vs Bambu Lab A1 Combo

The Bambu Lab A1 Combo and the Anycubic Kobra 3 are both designed for speed printing. But they approach multi-material printing from different angles.

- Printing System: The Bambu Lab A1 Combo uses an AMS (Automatic Material System) to handle multi-material changes easily. Anycubic Kobra 3 is paired with the ACE Pro with the same autoloading functionality. The ACE Pro has an active heating chamber that dries the filament as it prints. This feature is absent in the AMS.

- Build Volume: The Kobra 3 offers a build volume of 250mm x 250mm x 260mm. The Bambu A1 Combo, in comparison, provides 256mm x 256mm x 256mm, making their printable space very similar in practice.

- Print Speed: Both printers excel at speed, with the Kobra 3 reaching 600 mm/s and the A1 Combo coming in close. However, print quality at higher speeds is a key factor. Users have noted that while the Kobra 3 is fast, it can sometimes show imperfections at color transitions, while the Bambu Lab’s AMS system maintains consistency between changes.

- Material Handling: The A1 Combo’s AMS supports multiple materials without manual changes. The Kobra 3 handles PLA, PETG, and TPU well but lacks the support for high-temperature filaments like ABS or PC.

Anycubic Kobra 3 vs Prusa i3 MK3S+

The Prusa i3 MK3S+ is a well-established FDM printer. It’s known for its reliability and a solid ecosystem. The Kobra 3, on the other hand, pushes the envelope in terms of speed and automation.

- Build Volume: The Kobra 3’s 250mm x 250mm x 260mm build volume is larger than the Prusa i3 MK3S+’s 250mm x 210mm x 210mm. This gives the Kobra 3 more vertical printing space for taller models.

- Automation: The Kobra 3’s auto-leveling and Z-offset adjustment require minimal manual intervention. Whereas the MK3S+ relies on a semi-automated mesh bed leveling system. Both systems are easy to use, but the Kobra 3 removes the need for manual tweaks entirely.

- Speed and Noise: The Kobra 3’s silent mode and faster print speeds is appealing for home users who want quieter operation and faster prints. The MK3S+ is not as fast out of the box but is praised for its stability and consistent print quality at moderate speeds.

- Material Compatibility: The MK3S+ supports a bigger range of materials. It can print ABS, ASA, and more, thanks to its all-metal hotend and heated bed design. In contrast, the Kobra 3 optimizes performance for PLA, PETG, and TPU. The nozzle reaches 300°C, but the hotbed caps at 110°C.

Real World Applications

The Kobra 3’s speed and improved printing capabilities is useful for different projects:

- Prototyping and Functional Parts:

The Kobra 3’s large build area and quick speeds make it feel right at home with mechanical parts and concept models. You can rely on the auto-leveling system and filament flow control to keep things running smoothly. But if you’re planning to use heat-resistant filaments like ABS or PC, this isn’t the printer for you. It’s limited to PLA, PETG, and TPU. - Cosplay and Props:

This printer’s build size is ideal for printing larger costume pieces and props without splitting files. The tool-free hotend swap makes switching nozzles easy when you want to adjust layer thickness or switch to a different filament type. Just keep in mind that pushing higher speeds can lead to surface imperfections on intricate parts. It’s great for big armor plates, not as ideal for fine detailing. - 3D Printed Figurines and Terrain Models:

While it won’t outshine a resin printer when it comes to ultra-fine detail, the Kobra 3 can print large-scale figurines and terrain pieces well. It’s especially good when printed at moderate speeds. The 3D photo embossing feature in the Anycubic slicer is a quirky extra. It turns flat images into raised prints, though it feels more like a fun experiment than a core feature. - Home Projects:

Whether you’re printing custom organizers or replacement parts for gadgets around the house, the auto-resume feature has your back. If the power cuts out or the filament runs dry, the Kobra 3 picks up where it left off. That said, the filament detection isn’t foolproof—sometimes it throws a false alert, so you might need to tweak the settings if that happens.

Final Note

The Anycubic Kobra 3 feels like a printer designed to make fast, large-scale printing more accessible without overcomplicating things. The 600 mm/s max print speed, auto-leveling with LeviQ 3.0, and spacious 250mm x 250mm x 260mm build volume show that this machine targets users who want to complete projects quickly and with minimal hassle. The modular design and quick-swap hotend mean maintenance isn’t a chore. The adjustable touchscreen makes it a bit more comfortable when navigating the interface.

Of course, it’s not perfect. The filament compatibility is limited to PLA, PETG, and TPU. This can be frustrating if you’re used to working with higher-temperature materials. And while the vibration compensation system smooths out many high-speed prints, you might notice small artifacts on more detailed models.

Still, the Kobra 3 manages to take much of the guesswork out of printing with its auto-resume function, filament runout detection, and app-based monitoring. It’s a machine that does better in setups where speed and ease of use matter more than pushing the limits of fine detail or material variety.

If you’re after a 3D printer with multi-color printing capability that prioritizes convenience and fast results, the Kobra 3 could fit right into your workspace—just don’t be surprised if it takes a bit of tweaking now and then to get everything running exactly the way you want.