Creality Ender-3 V3 SE Review

Creality entered the 3D printing scene in 2014 and quickly became one of the most recognized brands for affordable home 3D printers. In 2018, they struck the market with the Ender-3. It’s a printer that gave users a larger build area, an open-source design, and solid print quality at a budget price. It was an instant hit, especially with beginners and tinkerers who wanted to modify their machines.

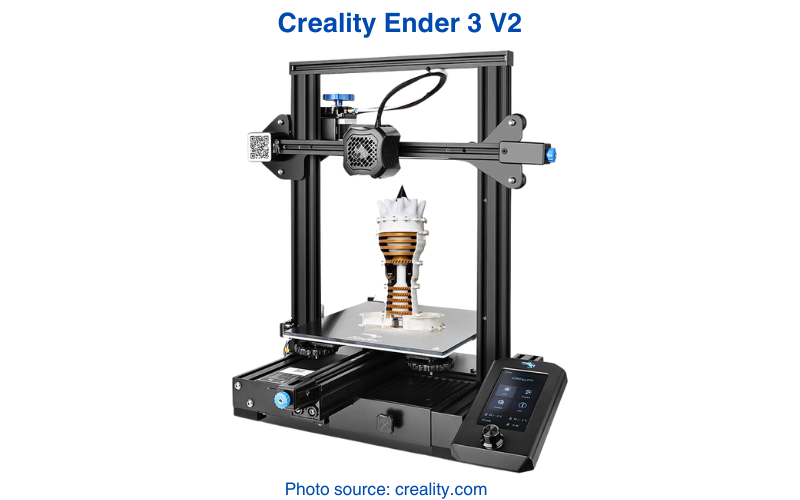

Following its success, Creality introduced the Ender-3 Pro with an upgraded power supply and sturdier components. Then, the Ender-3 V2 in 2020, which improved usability with a quieter motherboard, a color display, and better cable management. In 2022, they took a bigger leap with the Ender-3 S1, adding features like auto-leveling and a direct drive extruder for smoother filament handling.

The Ender-3 V3 SE is the latest iteration in this lineup, and it’s aimed at making 3D printing even more approachable. It focuses on a hassle-free setup, steady performance, and user-friendly features designed to remove some of the guesswork. In this review, we’ll break down what’s new, compare it to earlier versions, and see how it fits into the evolution of the Ender-3 series.

Design and Build Quality

The Ender-3 V3 SE sticks with the open-frame design that the Ender series is known for but adds a few smart upgrades. The aluminum frame keeps things sturdy during prints, while the updated gantry design helps reduce vibrations for smoother movement. One standout change is the improved cable management, which keeps the wiring neatly tucked away—great if you prefer a cleaner, less cluttered setup.

Creality also equipped this model with the “Sprite” direct drive extruder. It uses dual steel gears to grip the filament better, which helps prevent slipping or grinding. This is helpful if you’re printing with flexible filaments like TPU. The build volume stays the same at 220 x 220 x 250 mm. The print bed features a PC-coated spring steel sheet, making it easy to remove finished prints without hassle.

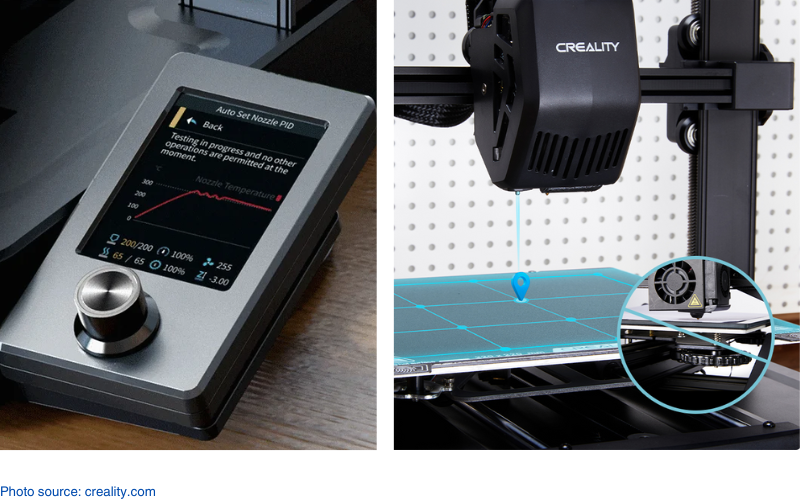

Instead of a touchscreen, Creality kept the 3.2-inch color display with a control knob. It’s simple and gets the job done, letting you adjust settings and start prints without any fuss. Overall, the Ender-3 V3 SE sticks to the basics while improving the parts that matter for a smoother, more user-friendly experience.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Medium-sized Build Volume | Build Volume: 220 x 220 x 250 mm |

| “Sprite” Direct Drive Extruder | Printing Speed: Up to 250 mm/s |

| CR Touch Auto-Leveling | Layer Height: 0.1 – 0.35 mm |

| Heated Print Bed | Printing Accuracy: 0.1 mm |

| Filament Run-out Sensor | Print Bed Material: PC Spring Steel |

| Motion Graphics UI | Nozzle Temperature: ≤260°C |

| Auto Filament Loading and Unloading | Heatbed Temperature: ≤100°C |

| Stable Dual Z-axis | Display Screen: 3.2″ Color Knob Screen |

| Power Loss Recovery | Nozzle Diameter: 0.4 mm |

| File Transfer: SD Card | |

| Supported Filaments: PLA, PETG, TPU (95A) |

The Ender-3 V3 SE comes with a set of upgrades that make the printing process easier and faster. The CR Touch auto-leveling system is a big help, taking care of bed calibration automatically so you don’t have to adjust things manually. The “Sprite” direct drive extruder can handle flexible filaments like TPU without jamming. Andt it works just as smoothly with standard materials like PLA and PETG.

The print bed’s PC-coated spring steel sheet helps with adhesion during the print and makes it simple to pop your finished model off when it’s done. Plus, the filament run-out sensor pauses the print if you run out of filament, so you can reload and pick up where you left off. File transfers are easy, too—you can load your designs using an SD card or a USB-C connection. These features come together to make the Ender-3 V3 SE feel like a printer built to save you time and reduce hassle.

Comparisons

Ender-3 V3 SE vs Ender-3 V2

The Ender-3 V3 SE builds on the foundation of the Ender-3 V2 but introduces several key improvements aimed at convenience and speed.

- Printing System: The V3 SE features a direct drive “Sprite” extruder. This handles flexible filaments like TPU more efficiently than the V2’s Bowden setup. The Ender-3 V2 sticks with a traditional Bowden extruder, which works well for standard filaments but struggles with flexible materials.

- Auto-Leveling: The V3 SE includes a CR Touch auto-leveling sensor for automatic bed calibration. On the other hand, the V2 requires a manual leveling process or an add-on sensor.

- Print Speed: The V3 SE reaches speeds of up to 250 mm/s, while the V2 is designed for more moderate speeds, generally around 60–100 mm/s.

- Display and Controls: The Ender-3 V2 features a 4.3-inch color display with a dial control. This is similar to the V3 SE’s interface. However, the V3 SE’s firmware is optimized for faster input and more responsive controls.

Ender-3 V3 SE vs Ender-3 S1

While the Ender-3 S1 and V3 SE share some similarities, they have different focuses.

- Extruder System: Both printers use a direct drive “Sprite” extruder, but the S1’s setup includes dual Z-axis motors for more stable vertical movement. The V3 SE sticks to a single Z-axis motor, keeping the design simple.

- Auto-Leveling: Both models feature CR Touch auto-leveling, though the S1’s 16-point calibration offers slightly more precision for larger prints.

- Build Volume: The build volume is identical at 220 x 220 x 250 mm for both models. So you’re not gaining extra space with the S1.

Real World Appllications

The Ender-3 V3 SE is built for different types of printing tasks. You may be working on something practical or just experimenting, this 3D printer holds up in real-world use:

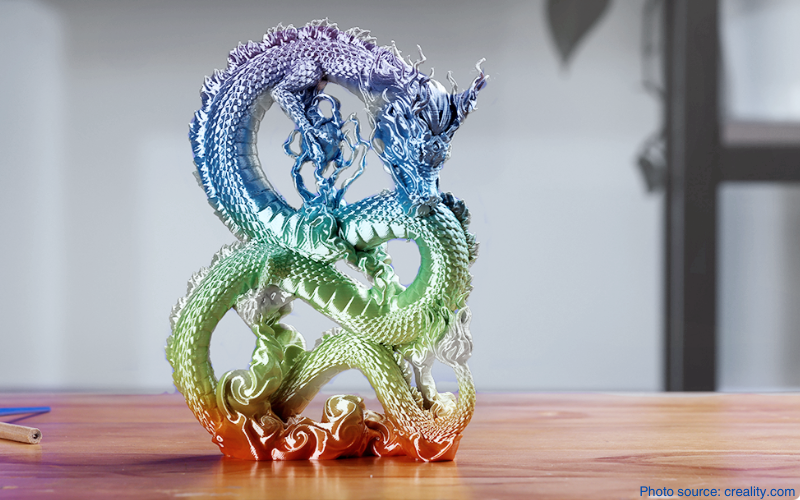

- Prototyping and Functional Parts: If you’re printing test pieces or replacement parts, the V3 SE’s fast print speeds help you get through multiple iterations quickly. The direct drive system also handles flexible filaments like TPU well. It can be useful for prints that need a little give, like hinges or grips.

- Hobby and Decorative Models: With its decent build space, this printer can handle things like figurines, cosplay props, or home decor projects. The auto-leveling system makes sure your first layers are consistent. This is especially helpful for prints that need fine details or multiple parts that fit together.

- DIY and Household Projects: Whether you need a new tool holder, a custom organizer, or replacement parts for around the house, the V3 SE makes it easy to print functional items. The print bed’s surface also makes removing finished prints simple—no more prying prints off with tools.

Final Note

The Creality Ender-3 V3 SE takes what made the Ender-3 series popular and adds smart upgrades to make printing easier and faster. The CR Touch auto-leveling means you spend less time adjusting the bed and more time printing. The “Sprite” direct drive extruder handles both standard and flexible filaments smoothly, making it a great fit for a wide range of projects.

With its 250 mm/s max print speed, the V3 SE is faster than old models. The build volume of 220 x 220 x 250 mm strikes a good balance for most everyday projects. And the PC-coated print bed makes removing finished prints simple—no scraping needed. Consider getting the Ender-3 V3 SE if you’re after a printer that simplifies setup and maintenance without losing performance.