Elegoo Jupiter SE Review

Resin 3D printers have become a popular choice for creators looking for exceptional print quality. These machines use UV-sensitive resin to produce models with smooth surfaces and sharp details. Their ability to capture intricate features makes them ideal for crafting miniatures, prototypes, and even industrial components. Unlike filament-based printers, resin printers create more refined prints, making them essential for projects that require high precision. In this article, we’ll take an in-depth look at this Elegoo Jupiter SE review. We’ll explore its key features, printing capabilities, and how it performs in real-world applications. Whether you’re a beginner or an experienced maker, this review will help you understand what the Elegoo Jupiter SE brings to the table and how it will be useful in your 3D printing projects.

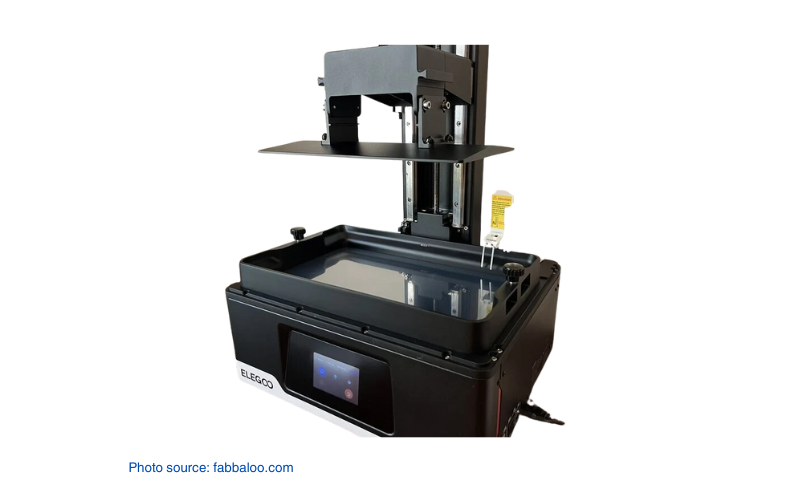

Design and Build Quality

The Elegoo Jupiter SE is built to be durable and efficient. Its sturdy frame supports its large build volume while reducing vibrations for steady print performance. With dimensions of 479.9mmx377.4mmx657.5mm, it fits well in both professional and workshop environments. The Z-axis features dual linear guide rails with a 0.02mm accuracy, ensuring smooth and stable vertical movement. This design keeps prints steady, even when working on taller models, reducing the chance of printing errors.

The build platform has a laser-carved surface that enhances print adhesion and simplifies print removal once a project is done. Its 4-point leveling system makes setup straightforward, with no need for repeated adjustments after the first calibration. The rotary handle allows for quick and easy installation and removal of the build plate.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 12.8″ 6K Mono LCD | Build Volume: 277.848 x 156.264 x 300 mm³ |

| Automatic Resin Management System | XY Resolution: 51 microns (5448×3064) |

| COB + Refractive Light Source | Z-Axis Accuracy: 0.02 mm |

| Efficient Cooling System | Layer Thickness: 0.01–0.2 mm |

| 4-Point Leveling System | Printing Speed: Up to 70 mm/h |

| Stable Z-Axis Movement | Light Source: COB+Refractive Light Source (405nm) |

| Laser-Carved Build Platform | Supported Software: ChituBox & Voxeldance Tango |

| Connection Method: USB | |

| Operation Screen: 3.5-inch resistive touch screen | |

| Operation System: EL3D-3.0.1 | |

| Dimensions: 479.9mm(L) x 377.4mm(W) x 657.5mm(H) |

The Jupiter SE combines cutting-edge features designed for resin 3D printing at a larger scale. Its 12.8-inch 6K monochrome LCD delivers a resolution of 5448×3064 with a 51-micron XY resolution, capturing every detail with impressive accuracy. The automatic resin management system keeps prints running smoothly by feeding and recycling resin, reducing interruptions and material waste. Its spacious build volume, efficient cooling, and precise Z-axis movement ensure consistent results even during long printing sessions.

Comparisons

Jupiter SE vs. Jupiter

The Jupiter SE and the original Jupiter serve different printing purposes, with the Jupiter SE emphasizing convenience through added features like automatic resin management.

- Build Volume: Both models provide a substantial build volume of 278 x 156 x 300 mm, suitable for large-scale projects.

- Resolution: Each printer is equipped with a 12.8-inch 6K monochrome LCD, delivering a 51-micron XY resolution for detailed prints.

- Resin Management: The Jupiter SE features an automatic resin feeding and recycling system, enhancing convenience and reducing waste—a functionality not present in the original Jupiter.

- Build Platform: The Jupiter SE’s vat comes standard with PFA film, which can improve print adhesion and ease of use.

- Enclosure Material: The original Jupiter boasts an all-metal enclosure, potentially offering enhanced durability compared to the materials used in the Jupiter SE.

Jupiter SE vs. Saturn 2

The Elegoo Jupiter SE and Saturn 2 serve different purposes in resin 3D printing, made for users with distinct project requirements. Here’s how they compare:

- Build Volume: The Jupiter SE has a larger build volume of 277.848 x 156.264 x 300 mm³. It’s suitable for big projects or batch printing. The Saturn 2 has a smaller build area of 219 x 123 x 250 mm³, focusing on compact yet detailed prints.

- Resolution: The Saturn 2 features an 8K monochrome LCD with a 28.5-micron XY resolution, delivering more detailed prints compared to the Jupiter SE’s 6K monochrome LCD with a 51-micron XY resolution.

- Light Source: Both printers use advanced light sources that ensure uniform light exposure, resulting in accurate prints with smooth surfaces.

- Resin Management: The Jupiter SE includes automatic resin feeding and recycling, ensuring continuous operation and reducing material waste. The Saturn 2 requires manual resin handling, making it less convenient for long prints.

- Ease of Use: The Jupiter SE’s automated resin system, combined with its 4-point leveling system, simplifies setup and reduces maintenance needs, making it more user-friendly for larger-scale projects.

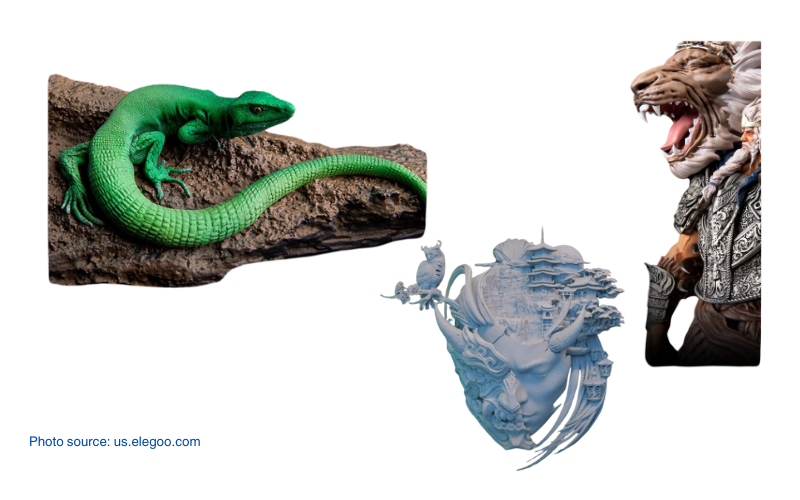

Real World Applications

The Elegoo Jupiter SE supports a variety of specialized tasks, making it a practical choice for creators and professionals who need more than a standard resin printer.

- Batch Production and Prototyping: With its large build area and automatic resin management, the Jupiter SE excels in small-scale production environments. Designers and manufacturers can print multiple parts simultaneously, making it ideal for product prototypes, assembly components, or promotional models.

- Long-Run Print Jobs: The automatic resin feeding and recycling system enables continuous printing, reducing downtime for extended jobs. This makes the Jupiter SE a reliable choice for long, complex prints in industries like product design or custom manufacturing.

- Industrial and Engineering Models: Engineers can create structural models, test parts, and precise mechanical components without constant monitoring. Its stable Z-axis movement ensures accurate prints, even for tall and detailed models.

- Educational and Medical Training Tools: The high resolution and large build area make it suitable for creating educational aids such as anatomical models, medical study replicas, or classroom tools for science and engineering programs.

Conclusion

The Elegoo Jupiter SE is a well-designed resin 3D printer made for creators needing a larger build area and dependable results. Its 12.8-inch 6K monochrome LCD produces detailed prints, while the automatic resin feeding and recycling system keeps the printing process uninterrupted. The stable Z-axis structure and dual linear guide rails maintain smooth and precise movement, even during lengthy print jobs.

Its generous build volume supports printing larger models or multiple items simultaneously. With features like a COB+refractive light source, advanced cooling, and an easy-to-use leveling system, the Jupiter SE delivers consistent performance. Whether focusing on miniatures, product prototypes, or artistic designs, this resin 3D printer from Elegoo produces accurate, high-quality output with minimal hassle.