Fastest 3D Printers

Back in the day, a “fast” 3D printer meant one that could shave some time off prints without messing up the details. Speeds around 50 to 100 mm/s were seen as impressive for consumer FDM printers. But as soon as you cranked up the speed, many printers struggled to keep things consistent—prints would warp, layers would shift, or the whole thing would fail. Finding the right balance between speed and quality was tough.

Now, the idea of what makes a fast 3D printer has changed a lot. With better hardware and smarter firmware, speeds of 300 mm/s and higher aren’t just for industrial machines anymore. Even consumer printers can produce fast, high-quality prints. But what really makes a 3D printer “fast,” and what should you look for when judging its speed?

What makes the Fastest 3D Printer:

- Print Speed:

This measures how fast the print head moves while extruding filament, usually in mm/s. Today’s high-speed printers can reach 300 mm/s or more. But speed alone doesn’t mean faster results—it also depends on acceleration, cooling, and extrusion. - Toolhead Acceleration:

Acceleration is how quickly the print head reaches top speed. A higher acceleration means the printer can hit those speeds even during short, detailed moves. Some newer printers hit up to 20,000 mm/s², allowing fast, smooth transitions between layers without print artifacts. - Cooling System:

Faster prints need better cooling so the filament can solidify quickly. Without strong part-cooling fans or precise airflow, prints can end up warped or smudged. High-speed printers use powerful fans and smart duct designs to direct airflow exactly where it’s needed. - Extruder:

A reliable extruder is key to pushing filament smoothly at high speeds. Direct-drive extruders are great for this because they feed filament directly into the hotend without long tubes. Dual-gear extruders also help by gripping the filament more securely to prevent slipping during fast movements. - Hotend Temperature:

The hotend needs to stay consistently hot as filament flows through quickly. If the temperature fluctuates, you’ll get uneven layers. Many high-speed printers have all-metal hotends that can handle temperatures over 300°C, which can print high-flow filaments like PETG or nylon blends. - Material:

The filament you use plays a big role in print speed. Fast PLA and high-flow PETG are designed to melt and extrude faster, helping you maintain clean prints at speeds of 300 mm/s or more. Standard filaments, like regular PLA or ABS, may struggle to keep up and cause stringing, under-extrusion, or layer shifts.

These are our best picks for the Fastest 3D Printers:

Elegoo Neptune 4 Plus

| Feature | Details |

|---|---|

| Print Speed | Advertised maximum of 500 mm/s, with optimal print quality achieved around 250 mm/s. |

| Max Toolhead Acceleration | Capable of up to 12,000 mm/s² with Klipper firmware, ensuring rapid movement and reduced print times. |

| Cooling System | Dual 4020 ball bearing blower fans direct airflow efficiently across the extruder for even cooling. |

| Extruder | Dual-gear direct extruder with a 5.2:1 reduction ratio for consistent filament flow, even with flexible filaments. |

| Hotend Temperature | All-metal hotend reaches up to 300°C, supporting materials like PLA, TPU, PETG, ABS, ASA, and Nylon. |

| Benchy Performance | Completes a Benchy print in approximately 16 minutes and 25 seconds at 250 mm/s. Minimal ringing, though some roughness appears at higher speeds. |

On the Elegoo line, Neptune series are the fastest 3D printers. Neptune 4 Plus tops everyone, with 16 minutes and 25 seconds printing a Benchy at standard settings.

Creality K1C

| Feature | Details |

|---|---|

| Print Speed | Maximum speed of 600 mm/s, with optimal results at 300 mm/s for cleaner prints. |

| Max Toolhead Acceleration | Reaches up to 20,000 mm/s², allowing the toolhead to reach top speed quickly, even during short moves. |

| Cooling System | Equipped with dual fans that direct airflow efficiently across the extruder, helping layers cool quickly to prevent defects. |

| Extruder | Direct-drive extruder capable of handling standard and reinforced filaments like carbon fiber blends, ensuring steady filament flow. |

| Hotend Temperature | The all-metal hotend reaches up to 300°C. It’s suitable for materials like PLA, PETG, TPU, ABS, ASA, and carbon fiber-infused filaments. |

| Benchy Performance | Prints a Benchy in approximately 13 minutes and 39 seconds at 300 mm/s. The result shows minimal ringing and slightly rough layers around curved sections. |

Creality has several fast models, but the K1C surpasses the others by 13 minutes and 39 seconds at its max acceleration. With a good cooling system, it doesn’t have any ringing but the layers can be a little bit jagged.

Bambu Lab X1 Carbon

| Feature | Details |

|---|---|

| Print Speed | Maximum print speed of 500 mm/s, with a default setting of 250 mm/s. Most users achieve the best print quality at around 150 mm/s. |

| Max Toolhead Acceleration | Reaches up to 20,000 mm/s², thanks to its CoreXY motion system, which enables quick and smooth transitions. |

| Cooling System | Dual part-cooling fans efficiently direct airflow around the extruder to prevent smudging and improve layer adhesion. |

| Extruder | Direct-drive extruder with hardened steel gears, designed to handle a variety of filaments, including carbon fiber-infused materials. |

| Hotend Temperature | All-metal hotend that reaches up to 300°C, supporting materials like PLA, TPU, PETG, ABS, ASA, and carbon fiber composites. |

| Benchy Performance | Completes a Benchy in approximately 18 minutes at 250 mm/s. |

Bambu Lab’s 3D printers are quite fast, with the X1 Carbon exceeding its siblings. However, it the Mini has the smoothest print at max acceleration with standard settings.

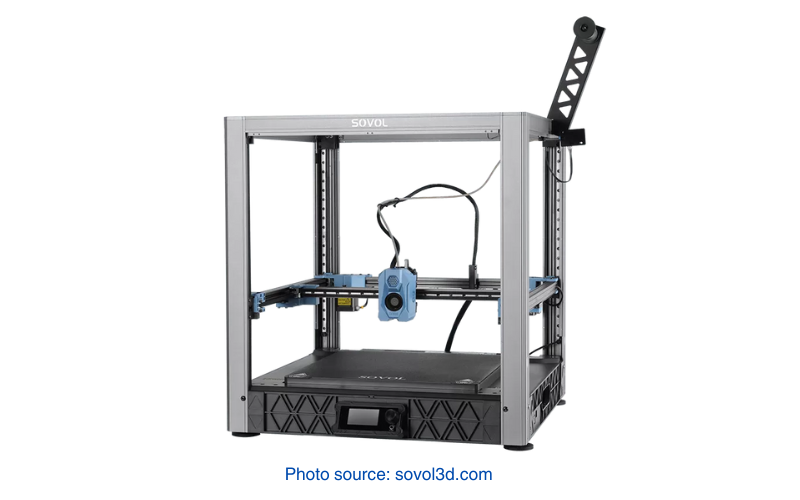

Sovol SV08

| Feature | Details |

|---|---|

| Print Speed | Topped out at 700 mm/s, but it’s set to 250 mm/s by default. Most people stick around 150 mm/s to keep the details clean. |

| Max Toolhead Acceleration | Goes up to 40,000 mm/s², meaning the print head can speed up and slow down really fast without missing a beat. |

| Cooling System | Comes with dual fans that blow plenty of air over the print to keep the layers from warping or getting messy. |

| Extruder | Direct-drive setup that feeds filament straight into the hotend. It handles tougher stuff like carbon fiber blends without slipping. |

| Hotend Temperature | Can hit 300°C, so you can print everything from basic PLA to stronger filaments like ABS, PETG, and carbon fiber-infused options. |

| Benchy Performance | 13 minutes and 25 seconds to print a Benchy. |

Among the SV siblings, SV 08 is the fastest at printing a Benchy: 13 minutes and 25 seconds at 250 mm/s. The result is solid, with only a little ringing on sharp edges and some roughness on curves.

Anycubic Kobra 2 Pro

| Feature | Details |

|---|---|

| Print Speed | Can reach up to 500 mm/s, but most users stick to around 300 mm/s for a good balance of speed and print quality. |

| Max Toolhead Acceleration | Hits up to 20,000 mm/s², meaning it speeds up and slows down quickly for shorter, faster prints. |

| Cooling System | Comes with an upgraded cooling system that directs airflow right where it’s needed to keep the layers solid and smooth. |

| Extruder | Uses a dual-gear direct-drive extruder that grips the filament firmly and feeds it consistently, even with flexible materials. |

| Hotend Temperature | The hotend reaches up to 260°C, so it can handle common materials like PLA and PETG, as well as tougher ones like ABS. |

| Benchy Performance | Prints a Benchy in about 15 minutes. |

The Kobra 2 Pro in the FDM series is the fastest with a clean overall Benchy print. It has minor ringing around sharp edges and some texture on curved parts.

AnkerMake M5C

| Feature | Details |

|---|---|

| Print Speed | Standard print speed of 250 mm/s, with a maximum speed of 500 mm/s. For optimal print quality, operating at the standard speed is recommended. |

| Max Toolhead Acceleration | In standard mode, it accelerates at 2,500 mm/s², while in fast mode, it reaches up to 5,000 mm/s². |

| Cooling System | Equipped with a cooling system designed to manage heat effectively, ensuring consistent print quality during extended operations. |

| Extruder | Features a direct-drive extruder capable of handling various filament types, providing reliable extrusion for diverse printing needs. |

| Hotend Temperature | The hotend can reach temperatures up to 260°C, accommodating PLA, TPU, PETG, and ABS. |

| Benchy Performance | Prints a Benchy in 23 minutes with well-defined features, minimal stringing, and no ringing around the porthole but struggled with the columns forming the cabin. |

Final Notes

The fastest 3D printers are not just about speed but also getting fast results without messing up your prints. FDM printers today can push speeds of 300 mm/s, 500 mm/s, or even more, thanks to better motion systems, stronger cooling, and smart extruder designs. Of course, cranking up the speed isn’t always enough. Without good cooling or the right filament, you can end up with stringing, shifted layers, or rough patches. That’s why it’s important to look at things like acceleration and cooling alongside the print speed.

If you’re looking to save time on your prints, these printers show that speed doesn’t have to come at the cost of quality. With all the improvements out there, fast 3D printing is more practical than ever.