Formlabs Form 4 Review

Formlabs has made themselves well-known in the 3D printing industry by developing products for various professional sectors. Their lineup includes advanced stereolithography (SLA) and selective laser sintering (SLS) 3D printers, such as the Form and Fuse Series. These are designed to meet the needs of industries like engineering, dental, medical, and manufacturing. In addition to hardware, Formlabs provides a comprehensive suite of materials engineered for specific applications. Their material library encompasses general-purpose resins, engineering resins, dental resins, medical resins, and SLS powders. Post-processing machines like Form Wash and Form Cure are developed to automate the cleaning and curing of printed parts to ensure optimal performance and finish. Their software tools, including PreForm for print preparation and Dashboard for printer management simplifies the printing process and control over production.

This Formlabs Form 4 Review examines how this large-format industrial resin 3D printer integrates into Formlabs’ extensive product ecosystem to deliver high-quality, efficient, and reliable solutions for professionals across various industries.

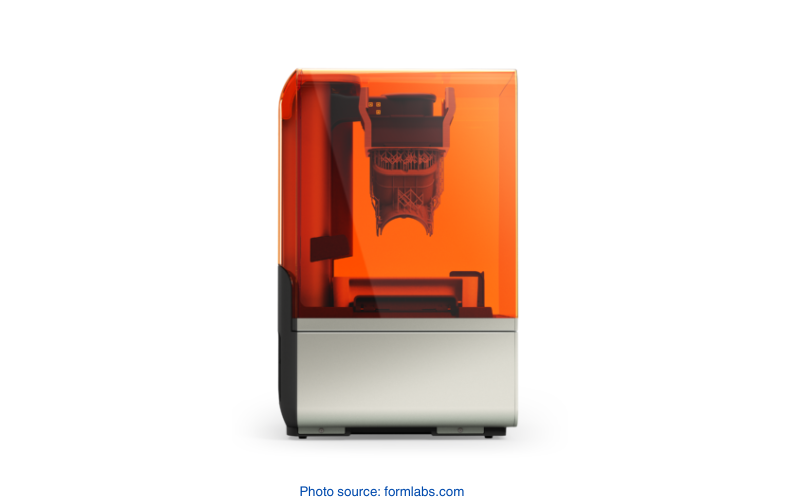

Design and Build Quality

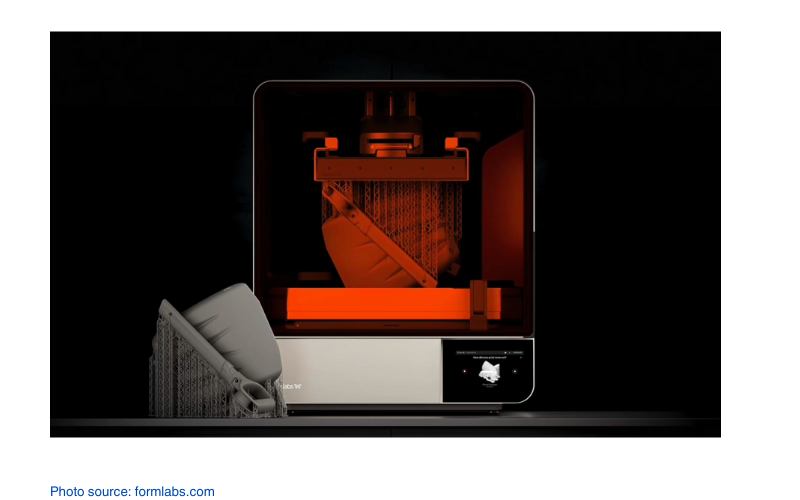

The Form 4 is designed for industrial-scale production, combining an extra-large build volume with brilliant engineering. Measuring 39.8 x 36.7 x 55.4 cm and weighing 18.3 kg, this machine is built for professionals who require a dependable printer that can handle heavy-duty tasks. Its build volume, 20.0 x 12.5 x 21.0 cm, has 30% more space than earlier models.

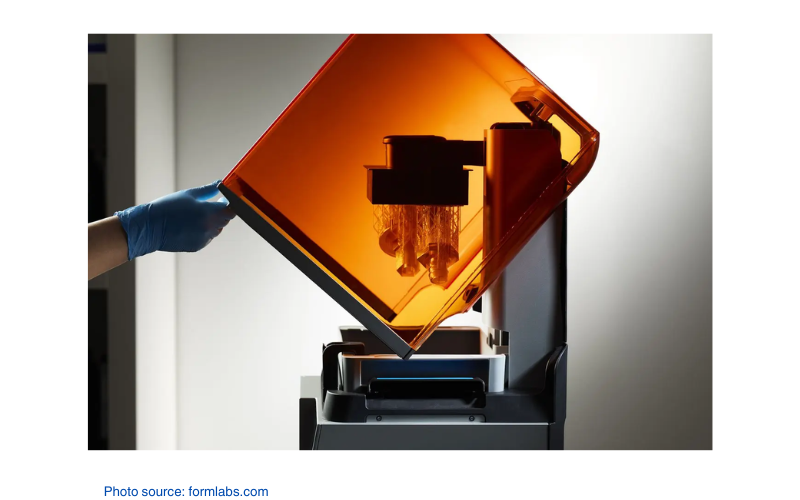

Formlabs has reimagined the resin cartridge system to streamline workflows. The new design fills faster and cuts plastic waste by 63%, supporting efficiency and sustainability. An upgraded mixing system ensures smooth operations and consistent output, even during long production runs. Form 4’s Low Force Display™ technology uses advanced lighting and optical components to cure resin layers with impressive speed. The complexity or size of the print doesn’t hinder performance.

The printer’s design also prioritizes practical usability. Its structure supports stability while being straightforward to operate and maintain. Every feature of the Form 4 serves industrial production, delivering sharp, smooth results while handling the rigors of high-demand manufacturing environments.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Industrial Scale Production | Technology: Masked Stereolithography (MSLA) |

| Low Force Display™ Technology | Printer Engine: Low Force Display™ Technology |

| Under 2-Hour Printing | Light Source: Backlight Unit: 60 uniform-wavelength LEDs, a plano-convex lens array, and integrated air cooling 405 nm optical wavelength 16 mW/cm² optical power intensity delivered to the cure plane 50 µm pixel size |

| 63% Less Waste | Printing Speed: Up to 100 mm/h |

| Post Processing Ease | XY Resolution: 50 microns |

| Automated Support Generation | Materials: 23 industry-leading Formlabs materials or third-party materials using Open Material Mode |

| Ultra-Fast Printing | Supports: Auto-generated |

| Workflow Integration | Software: PreForm, Dashboard, Fleet Control |

| Industrial Grade Materials | Supported File Types: STL, OBJ, and 3MF file input FORM file output |

| Open Material Mode | Connectivity: WiFi, Ethernet, USB 2.0 |

| Printer Control: 7″ 1280 × 800 resolution interactive touchscreen |

The Form 4 is built for industrial-scale production with its large build volume of 20.0×12.5× 21.0cm. With Low Force Display™ technology, the Form 4 rapidly cures resin layers using high-power LEDs, optical filters, and collimating lenses. This advanced system produces guaranteed consistent results, regardless of the complexity or size of the print. Most jobs finish in under two hours, with the printer running up to four times faster than earlier models.

The redesigned resin cartridge streamlines the workflow, filling faster while cutting down on plastic waste by 63%. An upgraded mixing system keeps production smooth and dependable. Post-processing is just as simple, thanks to tools like the Build Platform Flex, Form Wash, and Form Cure. The PreForm software simplifies model preparation, with features like adaptive layer thickness and automated support generation. Combined with Dashboard for remote monitoring, the Form 4 integrates well into professional workflows.

Comparisons

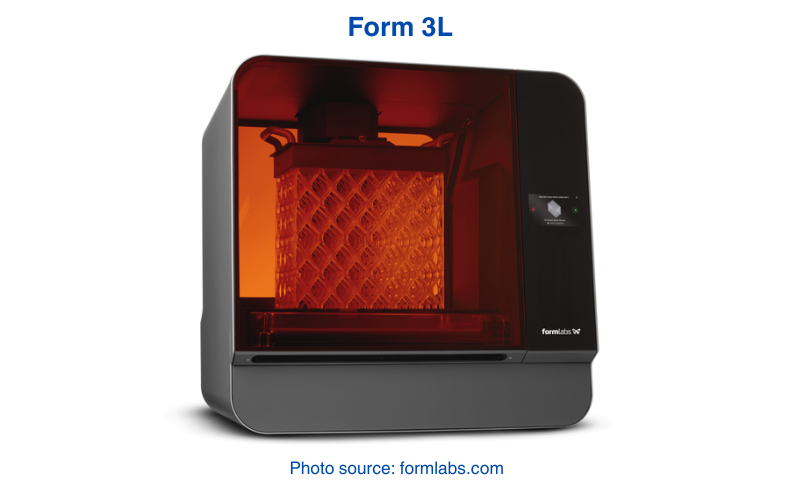

Form 4 vs Form 3L

The Form 3L and Form 4 are both industrial-grade resin 3D printers designed for professionals tackling large-scale production. While they share some core functionalities, the Form 4 introduces enhancements that can handle even more hectic workflows.

- Build Volume: The Form 3L has a larger build volume at 33.5 × 20 × 30 cm compared to the Form 4’s 20.0 × 12.5 × 21.0 cm. The Form 3L’s size is ideal for creating large, single-piece parts or batch-printing numerous components. While the Form 4 focuses on speed and material efficiency.

- Print Speed: The Form 4 completes most prints in under two hours, running up to four times faster than the Form 3L. This speed advantage makes it better suited for high-throughput workflows or time-sensitive production.

- Material System: Both printers are compatible with Formlabs’ extensive resin library, but the Form 4 introduces a redesigned resin cartridge system that speeds up filling and reduces material waste by 63%. This upgrade improves efficiency and sustainability.

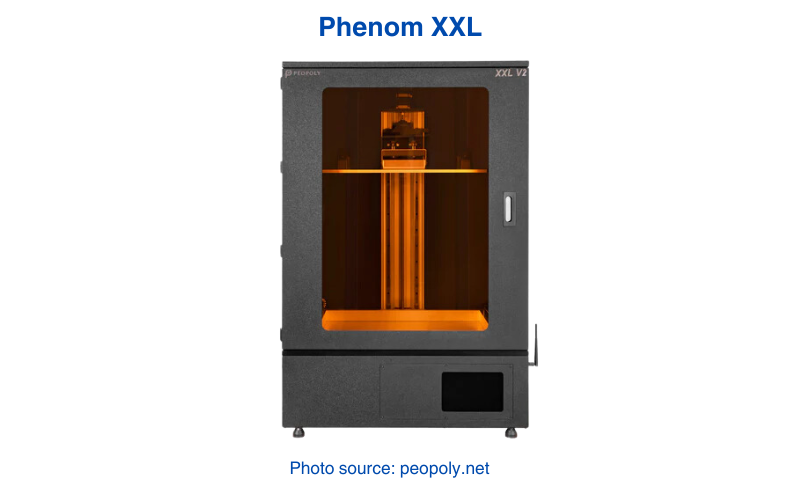

Form 4 vs Peopoly Phenom XXL

The Peopoly Phenom XXL and the Formlabs Form 4 are created for users who need industrial-grade capabilities, but their features and focus set them apart.

- Build Volume: The Phenom XXL has a massive 527 × 296 × 550 mm build volume. It’s one of the largest resin 3D printers on the market. The Form 4, while smaller at 20.0 × 12.5 × 21.0 cm, compensates with faster print speeds and a more streamlined workflow.

- Print Technology: The Phenom XXL uses MSLA technology, which relies on an array of LEDs and an LCD screen to cure resin layers. The Form 4 employs Low Force Display™ technology, which combines high-power LEDs and optical enhancements for sharper prints and consistent results, even on intricate parts.

- Post-Processing: The Form 4 integrates with tools like Form Wash and Form Cure, streamlining post-processing for professional users. The Phenom XXL lacks dedicated post-processing tools, leaving this step more manual and user-dependent.

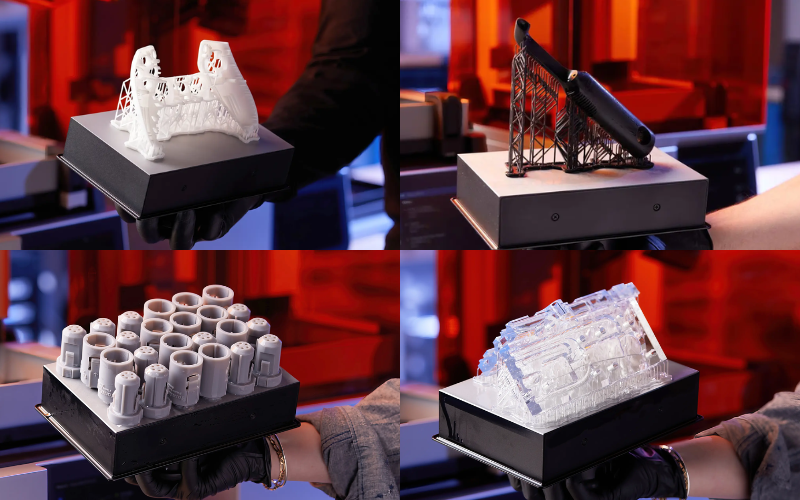

Real World Applications

The Form 4 has proven its effectiveness across various industries by enhancing workflows and enabling rapid prototyping and production. Here are specific examples demonstrating its impact:

- Consumer Products: OXO, a well-known kitchenware manufacturer, integrated the Form 4 into their product development process to accelerate prototyping. The speed and material versatility of the Form 4 allowed OXO’s team to produce multiple design iterations within a single day. It significantly reducred development time. For instance, prototypes of their popular vegetable peeler were printed in just over three hours. Form 4 enabled quick design validation and testing.

- Outdoor Equipment Manufacturing: Black Diamond Equipment utilized the Form 4 to scale their prototyping and testing capabilities. By adopting Formlabs’ advanced SLA printing technology, they streamlined their workflow, allowing for faster testing and iteration with fewer production delays. This integration enabled them to maintain high standards in product development while reducing lead times.

- Healthcare and Medical Devices: The Form 4B is a variant of the Form 4 designed for healthcare applications. It’s compatible with 15 additional biocompatible materials. This compatibility allows medical professionals to produce surgical guides, prosthetics, and anatomical models with high accuracy. It improved patient-specific care and surgical planning.

Conclusion

The Formlabs Form 4 sets a high standard for industrial-grade resin 3D printing, combining speed, advanced technology, and material flexibility in a thoughtfully engineered package. Its Low Force Display™ technology enables fast, accurate printing, whether you’re producing large parts or intricate assemblies. The redesigned resin cartridge system reduces waste and also streamlines workflows. It’s an efficient choice for high-volume production.

With applications spanning engineering, medical, dental, automotive, and consumer products, the Form 4 has proven its capabilities in diverse industries. If you’re creating prototypes at lightning speed or producing functional parts with exceptional quality, this 3D printer is a powerful tool for professionals looking to elevate their manufacturing processes. Its user-friendly software, intuitive workflows, and integrated post-processing tools ensure that it fits well into even the most demanding production environments.

For professionals in need of a reliable resin 3D printer that balances innovation with practicality, the Formlabs Form 4 delivers a performance that meets the requirements of modern industrial production.