Lynxter S300X Full Review

Since its launch in 2015, Lynxter has led the way in advanced 3D printing. They create machines for professional and industrial needs. Their printers are a go-to choice for industries like automotive, aerospace, healthcare, and product design, thanks to their reliability and high performance. The Lynxter S300X is the silicone 3D printer in their lineup that offers faster printing speeds, excellent print quality, and flexible material handling. This version meets high industrial standards and works with Lynxter’s materials and those from other brands. In this full review, we’ll explore the S300X’s features, technology, and performance. We’ll compare it with earlier models and other printers in the market.

Design and Build Quality

The Lynxter S300X – LIQ21 | LIQ11 fits neatly into any workspace. Measuring 991x720x 985 mm and weighs 135 kg, making it easy to place on a workbench. The closed chamber is equipped with a HEPA 14 filter and activated carbon. This system keeps the workspace safe by filtering out harmful particles and VOCs. Large capacity cartridges can hold enough material for big prints or multiple small ones. This reduces the need for frequent refills. The automatic calibration feature ensures the first layer prints correctly every time. Navigating the printer is straightforward with its 10-inch touchscreen. The interchangeable PEI composite bed supports rapid printing and maintains consistent performance across different materials. Video tutorials, printing profiles, and customer support can be accessed in the HUB platform, making it easy to get started and troubleshoot when needed.

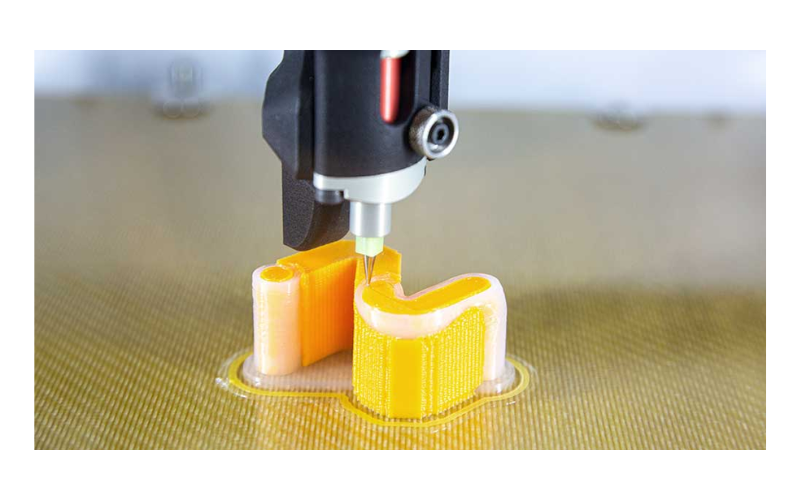

IDEX Technology (Two-part LIQ21 and One-part LIQ11)

The Lynxter S300X – LIQ21 | LIQ11 features a smart toolhead setup with two distinct parts: the LIQ21 and the LIQ11. The LIQ21 handles two-component materials, perfect for building the main structure of your print. Meanwhile, the LIQ11 manages single-component, water-soluble supports. This Independent Dual Extrusion (IDEX) system lets you print with two materials at the same time without them mixing. As a result, you can create more detailed and intricate designs effortlessly. The combination of LIQ21 and LIQ11 not only enhances design flexibility but also simplifies the removal of supports, making your workflow smoother and more efficient. Additionally, you can switch between single and dual extrusion based on your project needs, giving you the versatility to tackle a wide range of printing tasks with ease.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Dual Extrusion System | Toolhead Configuration: Two-part LIQ21 and one-part LIQ11 |

| Wide material compatibility | Build Volume: 300 × 250 × 200 mm |

| Precise and high-quality prints | X, Y, Z Resolution: X-Y: 12.5 μm, Z: 1.0 μm |

| Automatic calibration | Layer Height: 50 μm to 1 mm |

| Large build volume | Maximum Tool Speed X-Y : 500 mm/s, Z : 40 mm/s |

| User-friendly interface | Thermal Environment Heated Build Plate: 20°C to 80°C Heated Enclosure: 20°C to 40°C |

| Advanced air filtration system | Printing Materials: Medical RTV2 Silicone (5, 10, 25, 40 ShA), Industrial RTV2 Silicone (45 ShA), Polyurethane (50 to 85 ShA), LSR (coming soon), Epoxy (coming soon) |

| Open ecosystem | Automatic Calibration: Build Surface Leveling, Machine Geometric Correction, Tool Height Calibration, Inter-nozzle Offset Calibration |

| Machine Access Locking | Configurable Firmware: Customizable Lynxter Firmware (based on RepRap firmware), Simplify3D Software (slicer) |

| Manufacturing Job Security: Consumables Run-out Detection, Printing Resumption after Power Loss | |

| Control: Stand-alone Touchscreen and Web Interface |

The S300X is innovative with its dual extrusion system, letting you print two different materials at the same time. This feature supports various silicones and polyurethanes, and soon, it will also handle LSR and epoxy materials. The printer captures fine details with its high-resolution capabilities, making it perfect for complex designs. Its generous build area allows you to work on large projects or multiple smaller ones simultaneously. Setting up the printer is straightforward thanks to automatic calibration, which manages leveling and alignment for you. You can easily control the printer using the touchscreen or access it remotely through the web interface. Safety is well-covered with advanced filtration and a secure locking system. Additionally, the printer safeguards your projects by detecting when materials are low and can continue printing after a power outage. The open ecosystem lets you customize the firmware and use different slicing software to match your workflow.

Comparisons

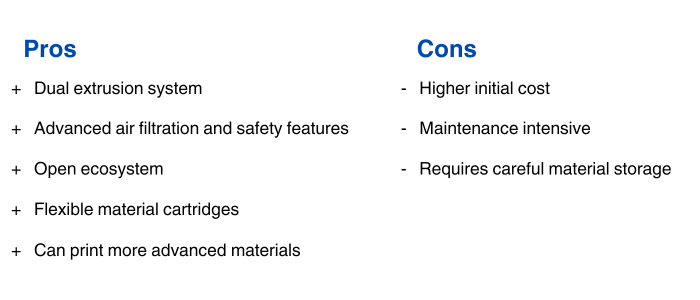

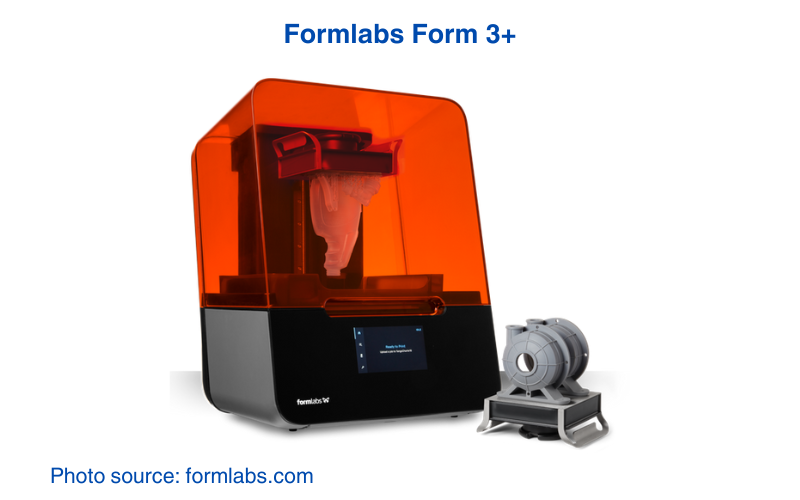

Lynxter S300X vs Formlabs Form 3+

The Lynxter S300X and the Formlabs Form 3+ are both made for professional use but specialize in different material types. While the Form 3+ excels in resin-based composite materials, the S300X is designed for silicone and polyurethane materials.

Build Volume: The S300X has a larger build area of 300 × 250 × 200 mm, allowing for bigger projects or multiple smaller prints simultaneously. In contrast, the Form 3+ has a build volume of 145 × 145 × 185 mm, which is ideal for smaller, detailed prints but limited for larger-scale productions.

Material Compatibility: The S300X supports a wide range of silicones and polyurethanes, including medical-grade RTV2 silicone and industrial-grade polyurethane. The Form 3+ primarily uses resin-based materials, which include the Formlabs Silicone 40A Resin, which is a composite of silicone and has most of its characteristics. Form 3+ is excellent for high-detail applications but does not have the same versatility in material types as the S300X.

Extrusion System: The S300X features an Independent Dual Extrusion (IDEX) system with two toolheads, allowing for multi-material printing without contamination. The Form 3+ utilizes a single extrusion system, focusing on high-quality single-material prints. This makes the S300X more suitable for complex parts requiring different material properties.

Lynxter S300X vs. Spectroplast SAM

The Lynxter S300X and the Spectroplast SAM are both advanced 3D printers designed for silicone additive manufacturing. While they share a focus on high-quality silicone prints, each has unique features for different industrial and medical applications.

Material Compatibility: The S300X can print silicones, including medical-grade RTV2 silicone (5, 10, 25, 40 ShA) and industrial-grade polyurethane (50 to 85 ShA). The Spectroplast SAM specializes in high-performance silicones, optimizing for applications that require exceptional material properties such as chemical resistance and thermal stability.

Extrusion System: The S300X features an (IDEX) system with two toolheads. On the other hand, the Spectroplast SAM utilizes a single extrusion system optimized for precise and uniform silicone flow. While the SAM does not support dual extrusion, its single system is highly efficient for producing consistent, high-quality silicone parts.

Build Volume: The S300X has a build volume of 300 × 250 × 200 mm, accommodating larger parts or multiple smaller prints in a single run. In comparison, the Spectroplast SAM has a build volume for medium-sized projects, which is sufficient for most specialized silicone applications but may be limited for exceptionally large or numerous prints. Users requiring larger or more frequent prints will find the S300X’s build volume more advantageous.

Industrial Applications

The Lynxter S300X – LIQ21 | LIQ11 transforms industrial operations by enabling on-demand production of custom parts. Its advanced capabilities support various industrial needs.

- Seals and Masking: The S300X prints surface treatment masks and caps tailored to specific requirements. These custom seals improve the quality and precision of manufacturing processes, reducing reliance on standard, off-the-shelf components.

- Maintenance and Emergency Repairs: Quickly produce parts for emergency repairs and routine maintenance. This on-demand capability minimizes downtime, ensuring that operations run smoothly without waiting for external suppliers.

- Soft Robotics: Develop and print components for soft robotics. The printer’s ability to handle flexible silicones and polyurethanes allows for the creation of intricate, movable parts necessary for advanced robotic systems.

- Production Efficiency: By integrating the S300X into their workflow, industries gain efficiency and responsiveness. The printer reduces production lead times and supports multiple projects simultaneously, boosting overall productivity.

- Material Quality: The S300X handles industrial-grade RTV2 silicone (45shA) and polyurethane (50 to 85 shA). These materials offer excellent durability and flexibility, making the printed parts suitable for demanding industrial applications.

Conclusion

The Lynxter S300X is a top choice for polyurethane and silicone 3D printing. Its dual extrusion system lets you print two materials at once, boosting creativity and efficiency. The large build volume accommodates both big projects and multiple small prints. Safety features like double HEPA filtration ensure a secure workspace. Automatic calibration simplifies setup, saving time and reducing errors. Its wide range of material versatility and a large build area, makes it ideal for industries such as automotive, aerospace, and healthcare. Whether you need custom seals, soft robotics parts, or medical devices, the S300X delivers reliable, high-quality prints. Overall, the Lynxter S300X – LIQ21 | LIQ11 is a powerful tool that enhances productivity and innovation in any professional setting.