Original Prusa i3 MK3S+ Full Review

Prusa Research, founded by Josef Prusa, began its journey in the early days of the RepRap project—an open-source initiative aimed at creating 3D printers capable of replicating themselves. The project fueled innovation and collaboration within the 3D printing community, laying the groundwork for what would become the Original Prusa line. The i3 MK3S+ launched late in 2020, with an improved set of features. Let’s take this model under the lens, examining its features, build, comparisons, and applications in this Original Prusa i3 MK3S+ full review.

Despite the emergence of newer 3D printing technologies and interfaces, the i3 MK3S+ continues to deliver an exceptional desktop printing experience. Its precision and user-friendly design make it a trusted choice for both beginners and experienced users alike. While some aspects of its hardware might seem a bit dated compared to the latest advancements, the MK3S+ consistently produces high-quality prints with minimal effort.

Design and Build Quality

Frame and Structure

The i3 MK3S+ features a sturdy and well-thought-out frame, made from high-quality aluminum extrusions. This solid structure provides excellent stability during printing and ensures the durability and longevity of the machine. The frame’s open design makes it easy to access the print area, making maintenance and adjustments straightforward.

Assembly Process

One of the standout aspects of the i3 MK3S+ is the availability of a build-it-yourself kit. Prusa Research has designed the assembly process to be as user-friendly as possible, providing detailed step-by-step instructions and high-quality components. The kit includes everything needed to assemble the printer, and the instructions are complemented by an online community and extensive support resources. This hands-on assembly experience familiarizes users with the inner workings of the printer to be confident in using and maintaining the machine.

Improved Features

The i3 MK3S+ incorporates several enhancements over its predecessors. One of the key upgrades is the SuperPINDA probe, which ensures precise and reliable first-layer calibration by compensating for any irregularities in the print surface. This improvement significantly enhances print quality.

Additionally, the i3 MK3S+ features a magnetic, removable PEI-coated spring steel print bed. This simplifies the process of removing completed prints. The Bondtech dual gear extrusion system gives superior filament grip and control, reducing the risk of slippage and ensuring consistent extrusion. The custom E3D V6 hot end contributes to accurate and efficient melting of filament.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Removable PEI-coated Print Bed | Build Volume: 250 x 210 x 210 mm |

| Bondtech Dual Gear Extruder | Print Speed: Up to 200 mm/s (recommended 60-100 mm/s) |

| SuperPINDA Auto Bed Leveling | Layer Height: 0.05-0.35 mm |

| Filament Runout Sensor | Nozzle Diameter: Standard 0.4 mm (interchangeable) |

| Custom E3D V6 Hotend | Max Nozzle Temperature: 300°C |

| Power Loss Recovery | Filament Compatibility: PLA, ABS, PETG, ASA, Flex, Nylon, PVA |

| Full Mesh Bed Leveling | Supported Filament Diameter: 1.75 mm |

| Connectivity: SD Card, USB | |

| Frame Material: Aluminum |

The i3 MK3S+ integrates a range of advanced features designed to enhance printing performance and user convenience. The removable PEI-coated spring steel print bed ensures excellent print adhesion and easy part removal. The Bondtech dual gear extruder provides reliable and consistent filament feeding. The SuperPINDA probe delivers precise bed leveling coupled with the filament runout sensor. In case of a power outage, the power loss recovery feature enables the printer to resume printing from the last known position. The custom E3D V6 hotend is capable of reaching high temperatures, allowing for the use of a wide variety of filaments, including advanced materials like nylon and flexible filaments.

Comparison

MINI+

One comparison worth noting is between the MK3S+ and the Prusa Mini+, which is a more compact and budget-friendly option. There are several key differences between them:

Build Volume: The i3 MK3S+ offers a larger build volume of 250 x 210 x 210 mm compared to the Mini+’s 180 x 180 x 180 mm, making it more suitable for larger projects.

User Interface: This model has a more advanced user interface with additional features, while the Mini+ has a more basic but user-friendly interface suitable for beginners.

Extruder: The i3 MK3S+ uses the Bondtech dual gear extruder, whereas the Mini+ uses a direct drive extruder designed for compact performance.

Price: The Mini+ is significantly more affordable, ideal for those new to 3D printing or with budget constraints. However, the i3 MK3S+ has more advanced features and a larger build volume, justifying its higher price.

Real World Applications

The Original Prusa i3 MK3S+ is a versatile 3D printer that excels in a wide range of real-world applications. Its robust features and reliable performance make it a preferred choice for various industries and hobbyist projects alike. Here are some of the key applications where the i3 MK3S+ truly shines:

Prototyping and Product Development

The i3 MK3S+ is widely used in prototyping and product development due to its precise printing capabilities and ease of use. Designers and engineers can quickly produce functional prototypes, test their designs, and make iterative improvements. The ability to use a variety of filament types, including PLA, ABS, PETG, and flexible materials, allows for the creation of prototypes that closely mimic the final product.

Research and Development

In research environments, the i3 MK3S+ is used to develop new materials, test innovative designs, and explore new applications of 3D printing technology. Its reliability and precision make it suitable for conducting experiments and gathering data in a controlled manner. Researchers can quickly produce and test new concepts, accelerating the pace of innovation.

3D Printing Business

For entrepreneurs and small businesses, the i3 MK3S+ can be used for starting and growing a 3D printing business. Its consistent high-quality output and versatility make it suitable for producing custom products, parts, and prototypes on demand. Businesses can offer services such as custom printing, design consultation, and rapid prototyping. The printer’s open-source firmware and hardware allow for easy customization and scalability. Additionally, the i3 MK3S+’s compatibility with a wide range of filaments means businesses can experiment with different materials.

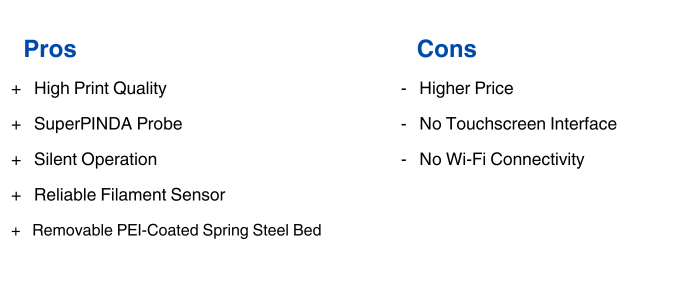

Conclusion

The Original Prusa i3 MK3S+ continues to be a remarkable choice in the 3D printing community. It reflects Prusa Research’s commitment to quality and innovation. With features like the SuperPINDA bed leveling and Bondtech dual gear extruder, this 3D printer is made for reliability and high performance. It’s a great match for educators, artists, engineers, and hobbyists, delivering consistent results across a variety of projects. Ultimately, the MK3S+ is a dependable and user-friendly machine that has earned its place in many workshops and studios.

Comments are closed.