Peopoly Phenom XXL Review

Peopoly, founded in 2015 by two friends with a shared interest in building 3D printers, started its journey with the Moai SLA printer. This laser-based system gained attention for producing high-quality prints at a more affordable price point compared to many competitors. Since then, Peopoly has developed more products for makers and professionals. In 2019, Peopoly introduced the Phenom series, a series of large format MSLA 3D printers. This lineup includes models like the Phenom Forge and the Phenom XXL, made for users who need larger build volumes and efficient resin-based printing.

Large format resin 3D printers, such as the Phenom XXL, bring notable advantages to 3D printing workflows. They can print larger, detailed models in a single run, reducing the need for assembly and improving productivity. These printers have become valuable tools for industries like prototyping, manufacturing, and design due to their ability to handle both large volumes and intricate details.

This Peopoly Phenom XXL review takes a closer look at the printer’s features, performance, and applications, providing insights into what makes it a significant option for users considering a large format resin 3D printer.

Design and Build Quality

The Peopoly Phenom XXL is undeniably large, with dimensions of 780 × 570 × 1120 mm and a weight of 115 kg. Its build volume of 527 × 296 × 550 mm sets it apart, offering significantly more printing space than earlier models like the Phenom L. This makes it ideal for creating larger models or printing multiple parts at once.

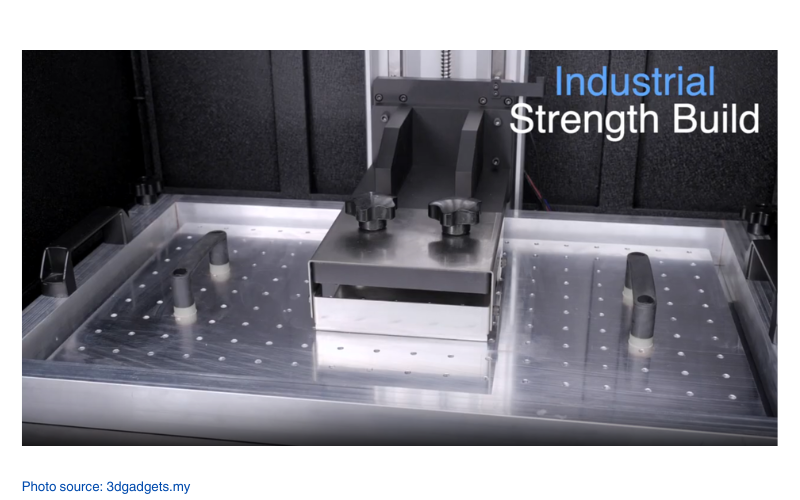

One key feature is the perforated build plate, designed to help the initial layers of resin anchor securely during printing. This reduces the chance of print detachment during longer jobs. The resin vat has a capacity of over 6 kg and includes handles for easier handling, along with a sliding and locking mechanism to maintain stability during operation. The 340-watt UV light source is supported by an upgraded cooling system to keep temperatures consistent and prevent overheating. Additionally, the Phenom XXL maintains compatibility with Peopoly’s Deft and Neo resins, known for their faster curing times, making it flexible for different types of projects.

Due to its size and weight, setting up the Phenom XXL requires ample space and a stable surface. However, for those working on large-scale prints, the printer’s thoughtful design choices help make the process more efficient and manageable.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Industrial Ultra Size Build Volume (85.8L) | Build Envelope: 527 × 296 × 550 mm |

| 4K LCD panel with 3840 × 2160 pixels resolution | Build volume: 85.8 L |

| Upgraded Resin Vat (6kg) | Max. resolution (XY): 0.137 mm |

| New Sliding and Locking Mechanism | Process: Vat photopolymerization (VPP) |

| Improved Cooling System | Technology UV light through mask > LCD (mSLA) |

| Resin Compatibility | Slicer Software: ChiTuBox |

| Perforated Build Plate | Light Source: 340 W UV |

With a massive build volume of 527 × 296 × 550 mm (85.8 liters), the Phenom XXL has one of the largest printing capacities available for a desktop resin 3D printer. It uses a 4K LCD panel with a resolution of 3840 × 2160 pixels, resulting in an XY pixel size of 137 microns. While the resolution may not match smaller desktop printers, this is a common tradeoff for the larger build area. The 340-watt UV light source ensures consistent exposure across the build plate, improving print consistency even at this scale. The upgraded resin vat can hold over 6 kg of resin and features convenient handles for easier refilling and maintenance. The perforated build plate improves print stability by securing the initial layers of the print, reducing the chances of detachment during longer jobs.

To support the high-powered UV light source, Peopoly added an improved cooling system to help maintain optimal operating temperatures. The Phenom XXL runs on ChiTu firmware and uses ChiTuBox for model slicing and preparation. The Phenom XXL is compatible with Peopoly’s Deft and Neo “fast” resins, giving users flexibility in material choice without needing specialized resins. The machine measures 780 × 570 × 1120 mm and weighs 115 kg, reinforcing its place as a large-format printer that requires a stable setup and adequate workspace.

Comparisons

Phenom XXL vs. Phenom L

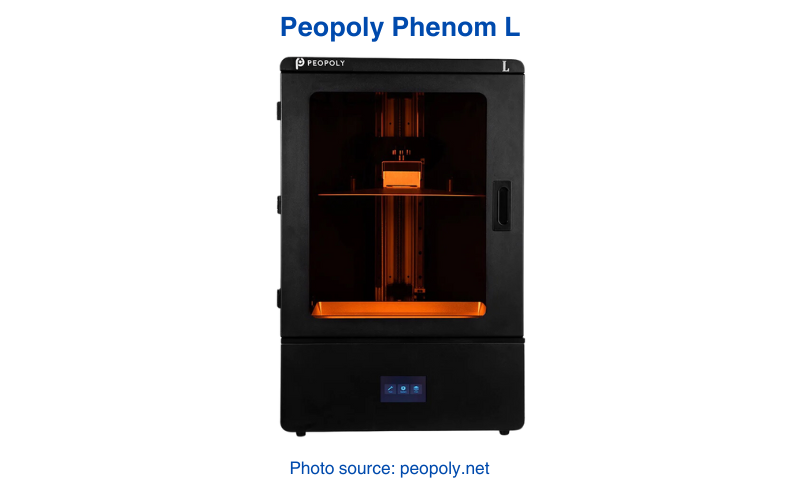

The Peopoly Phenom L and the Phenom XXL are large-format resin 3D printers designed for high-volume printing, but they serve different purposes based on their build size and capabilities.

- Build Volume: The Phenom L has a build volume of 346 × 194 × 400 mm, making it suitable for larger projects compared to standard resin printers. However, the Phenom XXL’s 527 × 296 × 550 mm build volume significantly surpasses it, offering more than double the capacity. This makes the XXL ideal for printing large models in a single piece or batch-producing multiple components.

- Resolution and Print Quality: Both printers use MSLA technology with 4K LCD panels, but the Phenom L has a finer XY resolution of 76 microns compared to the XXL’s 137 microns. This means the Phenom L is better suited for projects requiring more intricate details, while the XXL focuses on larger-scale prints where fine details are less critical.

- Weight and Size: The Phenom L is relatively compact, weighing around 42 kg and measuring 680 × 350 × 780 mm. In comparison, the Phenom XXL’s 115 kg frame and 780 × 570 × 1120 mm dimensions make it one of the heaviest and largest desktop resin printers, requiring a dedicated space and a stable platform.

Phenom XXL vs. Formlabs Form 3L

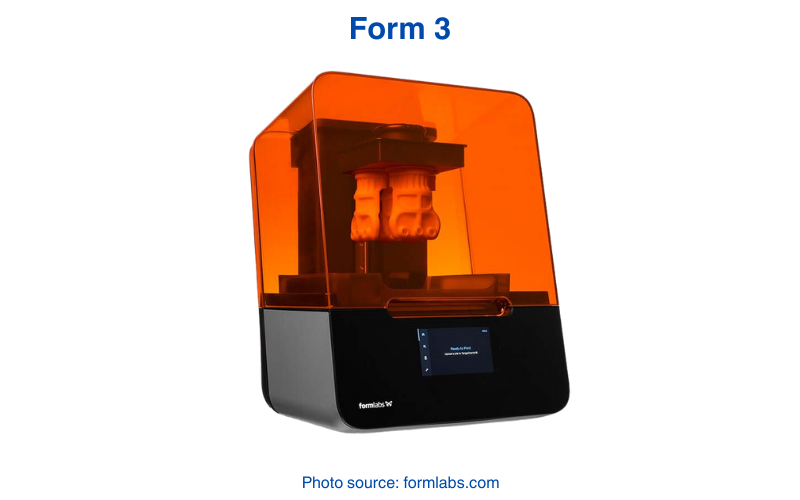

The Formlabs Form 3L and the Peopoly Phenom XXL are both large-format resin printers, but they differ in their approach to print quality, materials, and ecosystems.

- Build Volume: The Form 3L’s build volume of 335 × 200 × 300 mm is large by resin printing standards but is still much smaller than the Phenom XXL’s 527 × 296 × 550 mm capacity. While the Form 3L excels at mid-size models, the XXL is built for significantly larger parts or batch prints.

- Print Technology: The Form 3L uses Low Force Stereolithography (LFS) to reduce peel forces, resulting in smoother surfaces and fewer print failures. The Phenom XXL relies on MSLA technology, using a 4K LCD panel and a 340-watt UV light source to cure resin layers. While the XXL prioritizes scale and efficiency, the Form 3L focuses on surface quality and precision.

- Material System and Flexibility: Formlabs’ Form 3L works exclusively with proprietary resins, which can limit material choices and increase operating costs. In contrast, the Phenom XXL supports third-party resins, including Peopoly’s Deft and Neo fast-cure resins, giving users more flexibility to choose materials that fit their needs and budgets.

Real World Applications

The Peopoly Phenom XXL’s massive build volume and industrial-grade design is valuable for industrial applications and projects. Here’s a look at some real-world applications where the Phenom XXL excels:

- Entertainment and Props Production: The Phenom XXL’s large build area makes it perfect for printing large costume parts, props, or set pieces all in one go. Instead of splitting designs into smaller sections, creators can print full-scale pieces, cutting down assembly time. This is especially helpful for cosplay or film projects where time and visual impact are important.

- Engineering and Prototyping: For engineers working on functional prototypes, the XXL’s massive build volume allows them to print parts that reflect the actual size of their designs. Instead of assembling multiple smaller parts, they can test large components as a single unit, making it easier to check fit and function without compromising on structure.

- Medical and Educational Models: Medical professionals can print full-size anatomical models, like bones or organ replicas, for surgical planning or training purposes. The XXL’s capacity makes it possible to produce these models in one piece, providing more accurate and durable teaching aids.

- Architecture and Product Design: Architects can create detailed sections of buildings or large prototypes, such as furniture designs, in fewer prints. This allows them to present tangible, large-scale models to clients without needing excessive post-assembly work, helping to bridge the gap between digital designs and physical representation.

- Custom Manufacturing: The Phenom XXL is great for businesses that need to produce short runs of custom parts or molds. Whether it’s for industrial enclosures or niche components, the ability to print multiple items simultaneously means fewer print cycles and increased productivity.

Conclusion

The Peopoly Phenom XXL is built for those who need serious printing capacity. Its massive build volume lets you print large parts or batches without splitting them into sections. This can save you a lot of time, especially for projects like props, prototypes, and architectural models.

Even with its larger scale, the printer still handles smooth, detailed surfaces thanks to its 4K LCD panel and strong UV light source. The perforated build plate helps prints stay secure, and the large resin vat makes handling bigger jobs easier. Plus, you’re not locked into proprietary resins—you can use the ones that work best for your project.

If you’ve got the space and need a machine that can handle large-scale prints in one go, the Phenom XXL makes it possible without overcomplicating the process. It’s a practical tool for anyone working on big ideas that need more room to come to life.