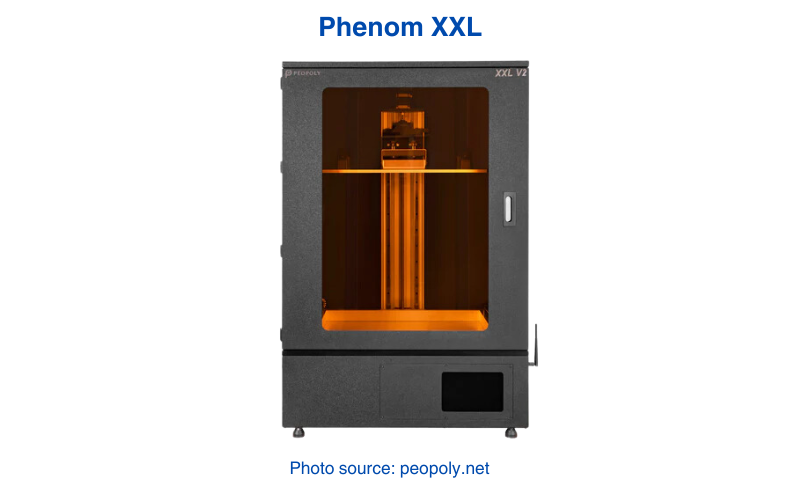

Peopoly Phenom XXL V2 Review

Peopoly began its journey in 2016 with a clear mission: to make resin 3D printing more available for more without compromising on quality or performance. The company quickly gained attention with its Moai series of SLA 3D printers. These delivered professional-level prints at a fraction of the cost of traditional industrial machines. The Moai lineup was praised for its open-source approach and modular design. It gave users the freedom to tweak and optimize their printing experience.

Building on this success, Peopoly shifted its focus to large format MSLA 3D printers with the Phenom series. These printers addressed a key demand in the market—the ability to print large, highly detailed models in a single session. The original Phenom and its successors, including the Phenom L and Phenom Noir, stood out due to their massive build volumes, high-speed printing capabilities, and durable components designed for continuous operation.

Large format resin 3D printers like those in the Phenom lineup have transformed workflows for industries such as architecture, prosthetics, and custom manufacturing. They excel at producing large-scale, intricate models with minimal assembly, saving time and reducing costs. In this Peopoly Phenom XXL V2 review will break down its features, performance, and how it stacks up for creators who need serious printing capacity without sacrificing print fidelity.

Design and Build Quality

The Peopoly Phenom XXL V2 is a massive machine designed for industrial production. The frame is made from a combination of durable metal and acrylic, giving it a solid and reinforced structure that can handle the demands of large-scale printing. Its dark gray and orange color scheme keeps it in line with the Phenom series’ recognizable style.

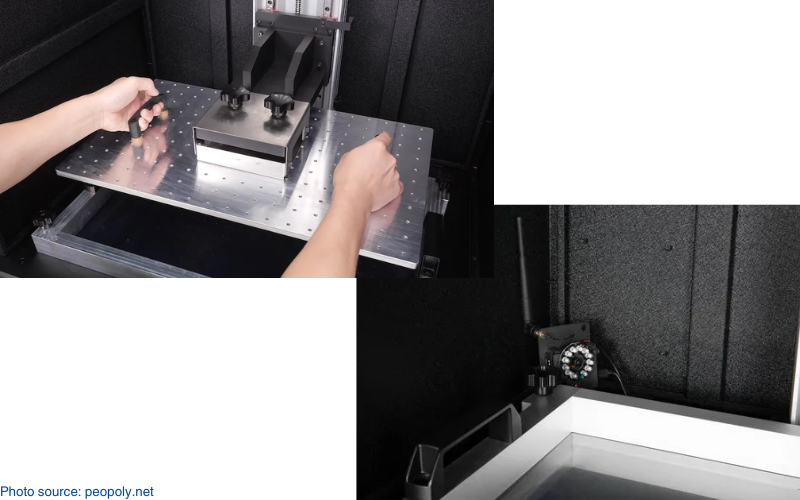

At 780 x 571 x 1120 mm and weighing 150 kg, this printer requires a dedicated space—it’s not something you can casually move around. However, the design choices for this printer make it easier to work with, despite its size. The 23.8-inch UHD 4K screen is securely fitted and provides a generous build area. While the large build plate features perforations and reinforced handles to make print removal less of a struggle. These details make a big difference when working with large prints that can be heavy and tricky to handle.

Its dual-rail Z-axis reinforces the vertical movement to keep everything stable during long print jobs. This minimizes wobble and helps avoid the layer misalignments that can ruin tall prints. Peopoly also designed the lower section of the printer with removable panels along the edges, so the maintenance and repairs are easier to execute.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Industrial Ultra Size Build Volume (85.8L) | Build Envelope: 527 × 296 × 550 mm |

| 4K LCD panel with 3840 × 2160 pixels resolution | Build volume: 85.8 L |

| Upgraded Resin Vat (6kg) | Max. resolution (XY): 0.137 mm |

| New Sliding and Locking Mechanism | Process: Vat photopolymerization (VPP) |

| Improved Cooling System | Technology UV light through mask > LCD (mSLA) |

| Resin Compatibility | Slicer Software: ChiTuBox |

| Perforated Build Plate | Light Source: 340 W UV |

The Phenom XXL V2’s defining feature is its massive 527 × 296 × 550 mm build volume, which significantly outscales smaller machines. For comparison, it’s over four times the size of the Formlabs Form 3L and 500% larger than the original Phenom. This makes it ideal for users who need to print large, continuous models without splitting them into sections.

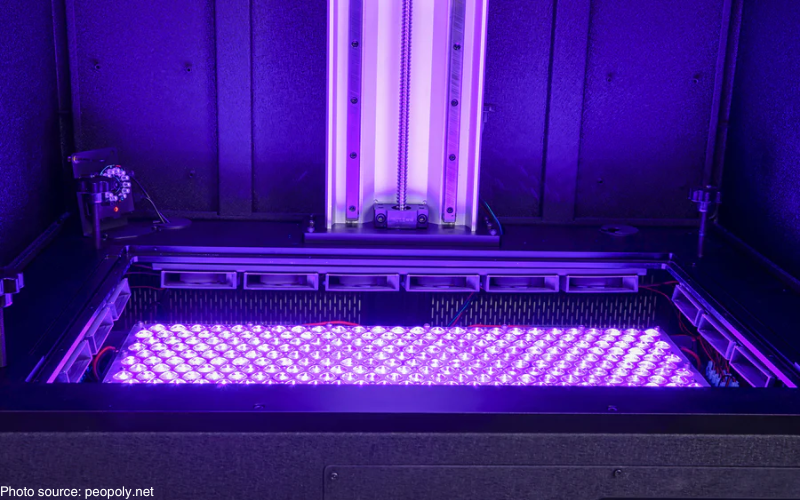

The 23.8-inch UHD 4K screen keeps the pixel pitch 137 µm resolution consistent across the entire print area, so you’re not giving up detail just because you’re printing something huge. Unlike older versions, the advanced parallel LED array improves light uniformity, reducing inconsistencies that can lead to failed prints or uneven surfaces.

The build plate features a perforated design to improve resin flow and prevent resin pooling, which can interfere with adhesion. The reinforced handles on the plate make handling large models more manageable, addressing a common challenge when working at this scale.

The dual-rail Z-axis helps keep the printing motion stable, minimizing wobble during taller prints. This is a crucial upgrade for maintaining layer accuracy on prints that reach the machine’s full 550 mm height.

Peopoly’s decision to include a larger 7-inch touchscreen improves navigation compared to the smaller interface on the original XXL. The printer also supports remote monitoring through its Wi-Fi connectivity and built-in infrared camera, allowing users to check on long-running prints from a distance.

Comparisons

Phenom XXL V2 vs Phenom XXL (Original)

The Phenom XXL V2 and the original Phenom XXL are designed for large-format printing. However, the V2 introduces several significant upgrades.

- Build Volume: Both models share the same massive build volume of 527 × 296 × 550 mm, allowing for large, single-piece prints.

- User Interface: The original XXL had a smaller 4.5-inch touchscreen, whereas the V2 is equipped with a larger 7-inch display, making navigation more intuitive.

- Light Source: The V2 uses an upgraded parallel LED matrix, which provides more even light distribution across the print area. This improves print consistency and reduces potential exposure errors.

- Cooling System: The V2 features improved cooling to reduce overall noise levels and maintain stable internal temperatures during long prints.

- Build Plate: The V2’s build plate is redesigned with perforations to improve resin flow and reduce resin pooling. The addition of reinforced handles makes it easier to remove larger prints.

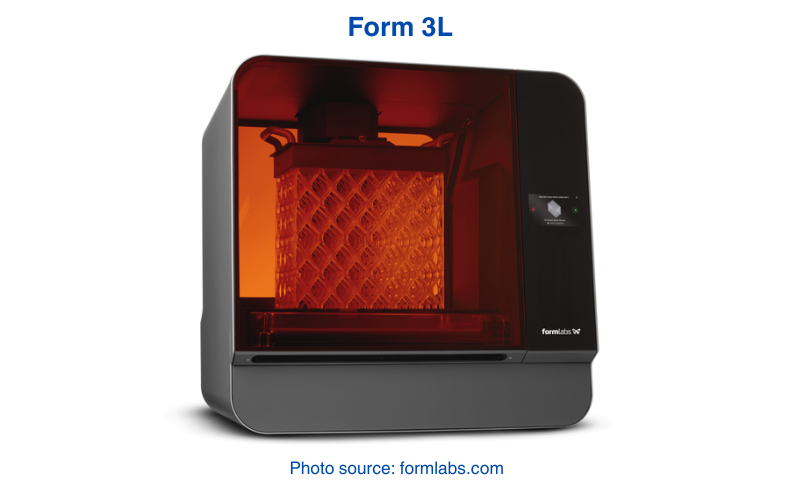

Phenom XXL V2 vs Formlabs Form 3L

The Formlabs Form 3L and the Phenom XXL V2 are both built for large-scale resin printing. But they target different use cases.

- Build Volume: The Form 3L has a build volume of 335 × 200 × 300 mm. It is much smaller compared to the Phenom XXL V2’s 527 × 296 × 550 mm. The XXL V2 can handle much larger models in a single print.

- Print Technology: The Form 3L uses Low Force Stereolithography (LFS). This technology reduces peel forces during printing, resulting in smoother surfaces. The Phenom XXL V2 uses MSLA technology, featuring an advanced 4K UHD LCD screen and parallel LED matrix for detailed and consistent layer curing.

- Material System: The Form 3L requires proprietary Formlabs resins. While the XXL V2 supports Peopoly’s Deft resin as well as third-party options. It is more flexible for different projects.

- Post-Processing: Formlabs provides an integrated ecosystem with tools like the Form Wash and Form Cure for automated post-processing. Peopoly does not offer dedicated post-processing tools. But, they recommend third-party cleaning and curing stations.

Real World Applications

Prototyping and Product Design:

The Phenom XXL V2’s expansive 527 × 296 × 550 mm build volume allows engineers to print large enclosures, casings, and mechanical components in a single piece. This eliminates the need to split and assemble parts, saving both time and reducing potential weak points. For example, a full-scale dashboard prototype that would require multiple prints on a smaller resin printer can be completed in one pass. It preserves dimensional accuracy and reducing post-processing by up to 60%.

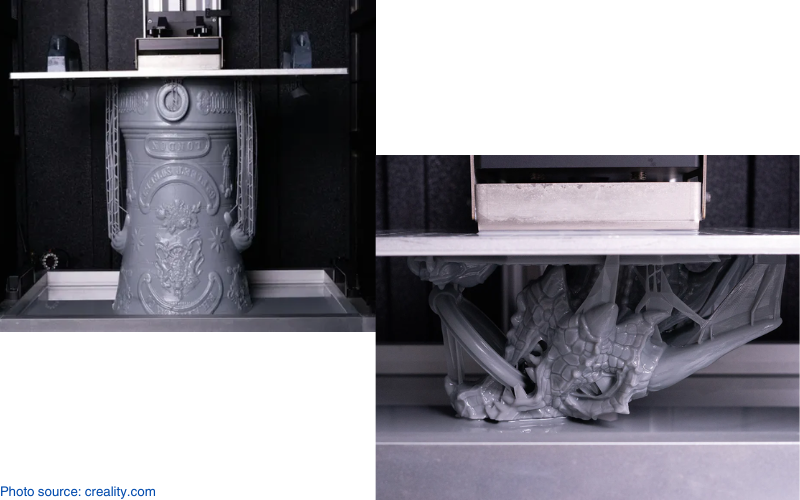

Entertainment and Props:

With its 23.8-inch UHD 4K screen and consistent 137 µm resolution, the XXL V2 excels at printing large props with complex details. This includes cosplay helmets, armor sections, and set decorations. Unlike smaller printers that require splitting large models into smaller sections, the XXL V2’s build capacity minimizes seams and joins so the structural integrity of larger pieces is improved. However, for oversized prints, users should factor in increased resin usage and extended curing times to maintain model durability.

Architectural Models:

The dual-rail Z-axis design provides the stability needed for tall, complex structures, allowing architects to print large building sections or detailed scale models without worrying about layer shifts or wobble. For instance, a full 1:100 scale cityscape model can be printed as a single piece, avoiding the inconsistencies that arise when merging separate segments.

Medical and Educational Models:

The XXL V2’s large print area is ideal for creating full-scale anatomical models. It can be a ribcage or organ replicas, used for surgical planning or educational purposes. Its industrial-grade 4K panel captures fine anatomical details, providing medical professionals with accurate, life-like visual aids. However, due to the printer’s high resin capacity, users should account for resin costs and longer post-curing times for larger models.

Medical and Educational Models:

The XXL V2’s large print area is ideal for creating full-scale anatomical models. It can be a ribcage or organ replicas, used for surgical planning or educational purposes. Its industrial-grade 4K panel captures fine anatomical details, providing medical professionals with accurate, life-like visual aids. However, due to the printer’s high resin capacity, users should account for resin costs and longer post-curing times for larger models.

Custom Manufacturing:

The Phenom XXL V2 supports short-run production of custom parts, molds, and jigs with a level of consistency typically found in much larger industrial machines. The 5-liter resin vat can handle extended prints without frequent refills, making it ideal for large molds or specialized fixtures. However, users handling full-volume prints should plan for resin usage of up to 5.8 kg per job, making batch production more efficient when printing multiple parts simultaneously.

Is it worth it?

The Peopoly Phenom XXL V2 takes large-format resin printing to a whole new level. With a 527 × 296 × 550 mm build volume, it’s designed for printing big models in one go. This means less time spent assembling smaller pieces and more time focusing on the final product. The 23.8-inch UHD 4K screen with 137 µm resolution ensures printing consistency across the entire print area.

One of the biggest improvements is the parallel LED matrix, which provides better light distribution for more reliable curing. The dual-rail Z-axis helps keep everything stable, even for tall prints, so you don’t end up with wobbly or misaligned layers. The perforated build plate with reinforced handles makes lifting and cleaning large prints much easier, which is a welcome change for anyone who’s wrestled with heavy resin prints.

The addition of Wi-Fi connectivity and an infrared camera means you can check on your prints remotely—a real game-changer for long print jobs. The XXL V2 also supports third-party resins, so you’re not locked into one brand. That said, with a 5.8-liter resin vat, printing at full capacity can use a lot of resin. It’s something to factor in if you’re working on multiple projects.

For applications like prototyping, prop-making, and custom manufacturing, the Phenom XXL V2 delivers the capacity and detail needed to take on complex, oversized projects. Its combination of clever design and functional improvements makes it a valuable tool for professionals looking to print big without the hassle of piecing things together.