Phrozen Sonic Mega 8K V2 Review

Phrozen has emerged as a leader in resin 3D printing, consistently redefining what’s possible in this field with its innovative products. Their lineup includes advanced resin 3D printers such as the Sonic Mini, Mighty and Mega series. Each is carefully designed to deliver exceptional results for professionals in industries like healthcare, visual arts, and industrial design. These printers are ideal for projects where fine details and high-definition output is required.

Beyond printers, Phrozen has developed a range of exceptional resins for various applications. These are made for performance and reliability needed in specialized work such as in dental molds and casting prototypes. Supporting this ecosystem are practical accessories like curing stations and heaters, designed to make the post-printing process efficient and straightforward. Their software is also part of this, which streamlines workflows and eliminates unnecessary complexity. In this review, we’ll explore how the Phrozen Sonic Mega 8K V2 contributes to this forward-thinking lineup.

Design and Build Quality

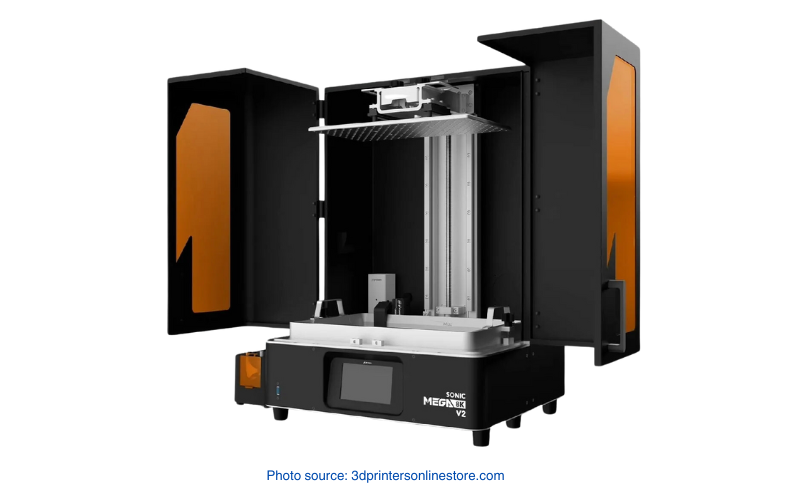

The Phrozen Sonic Mega 8K V2 is designed to handle large-scale resin printing with a focus on reliability and practicality. Its sturdy metal construction supports long-term use, and the 15-inch mono-LCD screen delivers high-resolution output across a large build area. This setup works well for professionals working on detailed, large-format projects.

The pre-calibrated build plate helps users get started quickly without additional adjustments. Z-axis improves stability, which uses dual linear rails and a ball screw system to keep movements steady. The resin vat is easy to manage during both setup and cleaning, streamlining the printing process.

For user convenience, the printer features a touchscreen interface positioned at the front, alongside USB and Ethernet ports for quick access. Cooling fans at the rear help maintain consistent operation during extended printing sessions.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 8K Printing Resolution (7680 x 4320 pixels) | Build Volume: 33 x 18.5 x 40cm cm |

| Large 15” Mono-LCD Screen | XY Resolution: 43 µm |

| Broad Build Volume for Large Models | Layer Thickness: 0.01-0.30 mm |

| Automated Resin Feeder (Pump & Fill System) | Maximum Printing Speed: 70 mm/hr |

| Pre-Calibrated Build Plate | Average Printing Speed: 400 layers/hr |

| Dual Linear Rails and Ball Screw Design for Stability | Light Source: 405nm ParaLED® Matrix 3.0 |

| Full-Metal Exterior | Slicer Software: CHITUBOX V2.2.0 or above |

| Plug-in Air Purifiers for Odor Control | System: Phrozen OS |

| User-Friendly Touchscreen Interface | Connectivity: USB | Ethernet |

| Display: 5″ Touch Panel | |

| Materials Supported: Resins suitable for 405nm LCD-based printers |

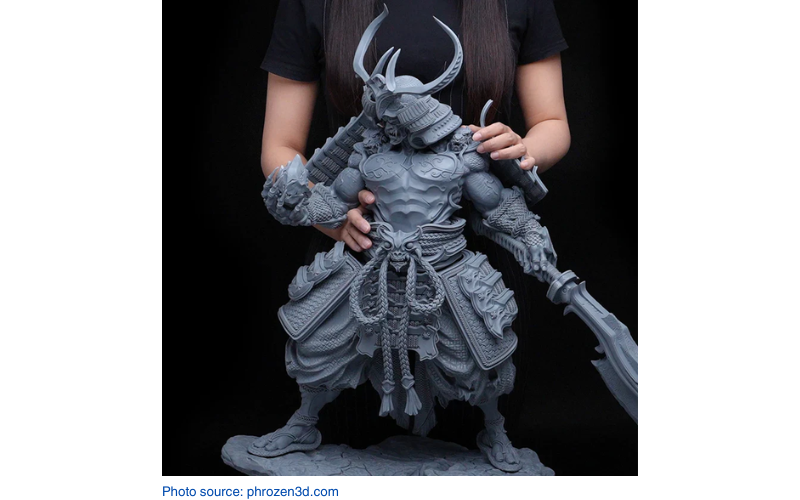

The Sonic Mega 8K V2 redefines large-scale resin 3D printing with its advanced 43µm resolution, delivering exceptional detail even on oversized models. Its 15-inch mono-LCD screen offers one of the largest printing areas available, making it a strong choice for those working on big projects without needing to split designs into smaller parts. With a build volume of 33 x 18.5 x 40 cm, it handles everything from large props to detailed prototypes with ease.

The pre-calibrated build plate eliminates the need for manual adjustments, saving time and effort for users ready to start printing. The Z-axis, equipped with dual linear rails and a ball screw system, ensures consistent and smooth movement for high-quality results. The full-metal body adds durability and keeps the printer stable during long print sessions, even when dealing with heavier models.

A 5-inch touchscreen display is in front, and the USB and Ethernet ports simplify file transfers and management. Additional features like the automated resin feeder and plug-in air purifiers enhance convenience, making the Sonic Mega 8K V2 a practical tool for professionals tackling complex projects.

Comparisons

Sonic Mega 8K V2 vs Sonic Mega 8K

The Sonic Mega 8K V2 improves upon the original Sonic Mega 8K by introducing features that enhance workflow and usability, making it more efficient for large-scale printing tasks.

- Build Volume: Both models share the same large build volume of 330 x 185 x 400 mm. Both are ideal for big projects and batch production.

- Resolution: Both printers deliver 43µm XY resolution with an 8K mono-LCD screen, producing detailed results for large-format models.

- Resin Management: The Sonic Mega 8K V2 introduces the automated resin feeder (Pump & Fill system). It which prevents mid-print failures caused by running out of resin. This feature simplifies resin handling and reduces downtime compared to the manual process required by the Mega 8K.

- Air Purification: The V2 includes dual plug-in air purifiers to minimize odors, a feature absent in the Sonic Mega 8K.

- Printing Speed: The V2’s high-speed printing system enables faster settings compared to the Sonic Mega 8K, cutting production times for large-scale models.

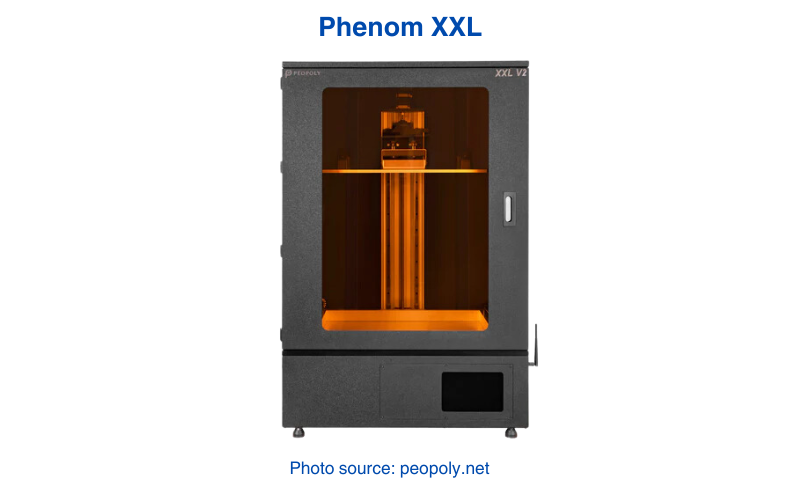

Sonic Mega 8K V2 vs Peopoly Phenom XXL

Both the Sonic Mega 8K V2 and the Peopoly Phenom XXL cater to large-scale 3D printing, but they differ significantly in their approach and feature sets.

- Build Volume: The Phenom XXL has a significantly larger build volume of 527 x 296 x 550 mm compared to the 330 x 185 x 400 mm of the Mega 8K V2. This makes the Phenom XXL better suited for extremely large models or massive production batches.

- Resolution: The Mega 8K V2 delivers sharper details with its 43µm XY resolution, while the Phenom XXL operates with a lower resolution due to its larger screen size.

- Printing Speed: The Mega 8K V2 features a high-speed printing system that accelerates production. Whereas the Phenom XXL typically requires more time for prints of similar scale.

- Resin Management: The Mega 8K V2’s Pump & Fill system automates resin handling, reducing interruptions during printing. The Phenom XXL relies on manual resin management, which can slow down workflows.

- Post-Processing: The Phenom XXL requires manual post-processing, while the Mega 8K V2 integrates features like dual air purifiers for better workspace management.

Real-World Applications

The Phrozen Sonic Mega 8K V2 has been instrumental in various industries. It enables professionals to achieve remarkable results in their industry. Here are some specific applications:

1. Product Design and Prototyping

Case Study: Bicycle Saddle and Handlebar Prototyping

Product designers have utilized the Sonic Mega 8K V2 to rapidly and affordably prototype bicycle saddles and handlebars. The printer’s large build volume allows for the creation of full-scale prototypes, facilitating detailed visualization, testing, and refinement. This capability accelerates the development process, reducing time from concept to final product.

2. Automotive Engineering

Case Study: Wind Tunnel Testing by Innoptus Solar Team, Belgium

The Innoptus Solar Team employed the Sonic Mega 8K V2 to produce components for wind tunnel testing. Traditional prototyping methods were both expensive and time-consuming. With the printer’s substantial build volume, multiple aerodynamic fins were printed simultaneously, significantly reducing production time while delivering results comparable to injection-molded parts.

3. Medical Prosthetics

Case Study: Animal Prosthetics by My Animal Soulmate, Taiwan

A volunteer group in Taiwan, My Animal Soulmate, leveraged the Sonic Mega 8K V2 to create custom-fit prosthetics for animals. The printer’s capacity for personalized creation enabled the rapid development of a prosthetic limb for a puppy, enhancing its mobility and quality of life.

4. Automotive Component Manufacturing

Case Study: Steering Wheel Hub Molds by Innoptus Solar Team, Belgium

The Sonic Mega 8K V2 was used to create molds for steering wheel hubs, offering a cost-effective alternative to traditional milling processes. The printer delivered smooth, polished results directly, saving time and resources typically spent on additional finishing processes.

Conclusion

The Phrozen Sonic Mega 8K V2 sets a new standard for large-format resin 3D printing. With its massive build volume of 330 x 185 x 400 mm and an industry-leading 15-inch mono-LCD screen, this printer delivers 8K resolution that captures the finest details. The automated resin feeder reduces interruptions, and the dual linear rails with a ball screw system keep prints stable and consistent, even during long sessions.

Product prototyping, medical applications or even automotive engineering, the Sonic Mega 8K V2 proves its capabilities across different industries. Its pre-calibrated build plate, user-friendly touchscreen, and practical design features make it a reliable choice for professionals working on ambitious projects. With additional improvements like plug-in air purifiers and a high-speed printing system, it is clear that this printer is designed for efficiency.