Phrozen Sonic Mini 4K Review

Phrozen is a Taiwan-based company that builds high-performance resin 3D printers at prices that are within reach for makers of all levels. Since starting in 2016, Phrozen has worked to bring advanced 3D printing technology to more people by creating printers that are powerful yet easy to use. Resin 3D printers have changed how people approach 3D printing by delivering smoother surfaces and lifelike results. They use UV light to harden liquid resin, creating models with fine features that are hard to match with other types of printers. This makes them popular in areas like miniature making, dental modeling, and custom jewelry design. In this article, we’ll take a close look at one of Phrozen’s popular models, the Phrozen Sonic Mini 4K. This Phrozen Sonic Mini 4K review will break down its key features, performance, and why it has gained attention in the resin 3D printing space.

Design and Build Quality

The Phrozen Sonic Mini 4K packs practicality into a compact frame, making it a great fit for different workspaces. With dimensions of 23 x 23 x 34 cm and a weight of only 5 kg, it’s easy to place on a desk or move around as needed. Its sturdy metal body keeps the printer stable during operation, helping maintain consistent performance throughout printing sessions.

The front-facing 2.8-inch touch panel keeps controls straightforward. You can adjust settings, preview files, and start prints with just a few taps. Its responsive interface simplifies the entire printing process, cutting down on setup time. A USB port on the side makes transferring files quick and convenient. This thoughtful placement minimizes cable clutter, keeping your workspace neat. The Sonic Mini 4K’s is both practical and efficient to make resin 3D printing accessible for beginners.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 4K Mono LCD | Build Volume: 13.4 x 7.5 x 13 cm³ |

| 6.1-inch Screen | XY Resolution: 35μm (3840 x 2160) |

| ParaLED Matrix 2.0 Light Source | Layer Thickness: 0.01–0.30 mm |

| Long-Lasting Screen | Maximum Printing Speed: 80mm/h |

| 80mm/h Fast Printing Speed | Supported Software: ChiTu Box V1.6.5 |

| Open Material Platform | Connection Method: USB |

| Multi-Resin Compatibility | Resin Compatibility: Phrozen Aqua-Gray 4K and third-party resins |

| Operating System: Phrozen OS | |

| Operating Screen: 2.8-inch touch panel | |

| Dimensions: 23 x 23 x 34 cm³ |

The Phrozen Sonic Mini 4K is built for fast and reliable resin 3D printing with impressive technical capabilities. Its 6.1-inch monochrome LCD screen features a high-resolution display of 3840 x 2160, producing sharp prints with 722 PPI, setting a new benchmark in its class. With a layer thickness range from 0.01 to 0.30mm and a maximum print speed of 80mm/h, it handles even complex designs with ease. Its advanced ParaLED Matrix 2.0 light source ensures even UV light exposure across the entire build area.

Transferring files is quick and straightforward with its USB data transfer system. It works best with Phrozen Aqua-Gray 4K resin but also supports third-party resins. The Sonic Mini 4K runs on Phrozen OS and uses the well-known ChiTu Box slicer. Its compact size and solid build make it a dependable choice for both personal and professional projects.

Comparisons

Sonic Mini 4K vs. Sonic Mini

The Sonic Mini 4K and Sonic Mini target different types of users by balancing ease of use and technological advancements.

- Ease of Use: The Phrozen Sonic Mini 4K features a high-resolution 4K monochrome LCD. It produces sharper prints and smoother surfaces than the original Sonic Mini. While both models are beginner-friendly, the Sonic Mini 4K’s upgraded screen reduces print times to just two seconds per layer, making it faster and more efficient. The original Sonic Mini, with its standard LCD, prints more slowly and needs more frequent screen replacements.

- Printing Technology: The Sonic Mini 4K uses a ParaLED Matrix 2.0 light source, delivering even UV light coverage for consistent results. The original Sonic Mini, equipped with an older light source, may produce uneven exposure on larger models.

- Build Quality and Design: Both printers share a small and lightweight design. However, the Sonic Mini 4K’s metal frame is more stable during printing. The original Sonic Mini, while sturdy, has a simpler build that may require more maintenance over time.

Sonic Mini 4K vs. Sonic Mighty 4K

The Sonic Mini 4K and Sonic Mighty 4K are designed for different user needs by balancing detail accuracy and production scale.

- Print Volume and Application: The Sonic Mini 4K is perfect for small-scale projects like miniatures and highly detailed models. This is due to its 6.1-inch build area and 35μm XY resolution. In contrast, the Sonic Mighty 4K, with its larger build volume, is better suited for bigger projects such as cosplay props and large prototypes.

- Workflow Efficiency: The Sonic Mini 4K excels at producing finely detailed prints, which is better for printing detailed designs. The Sonic Mighty 4K, designed for larger projects, can handle multiple models simultaneously, cutting down overall printing time.

- Resin Compatibility and Material Handling: Both models work well with Phrozen Aqua-Gray 4K and various third-party resins. However, the Sonic Mighty 4K’s larger resin tank supports extended printing sessions. The Sonic Mini 4K, on the other hand, has a compact resin system that is more suitable for smaller, detail-oriented tasks.

Real World Applications

The Phrozen Sonic Mini 4K delivers high-resolution prints that fit into a range of creative and professional fields. Here are some practical ways people use this printer every day:

- Miniature Model Making: Tabletop gamers and model builders create lifelike miniatures and custom game pieces with crisp features. Small elements like armor designs and facial expressions come out sharp and clear, making game setups and displays more realistic.

- Dental and Medical Prototyping: Dental labs can use the Sonic Mini 4K to make dental models, such as orthodontic molds. It speeds up the creation process, helping dental professionals reduce lab turnaround times.

- Jewelry Design and Manufacturing: Jewelry makers can print wax models for casting rings, earrings, and pendants. The printer captures engraved patterns and fine design elements, making it easier to refine and finalize products.

- Product Prototyping and Engineering: Engineers and product developers can print custom parts, prototypes, and electronic casings. Its fast printing speed supports product development while keeping models accurate to design specifications.

- Education and Research: Schools and research labs use the Sonic Mini 4K for STEM projects and technical experiments. Students and researchers print experimental components and hands-on learning tools to support academic work.

Conclusion

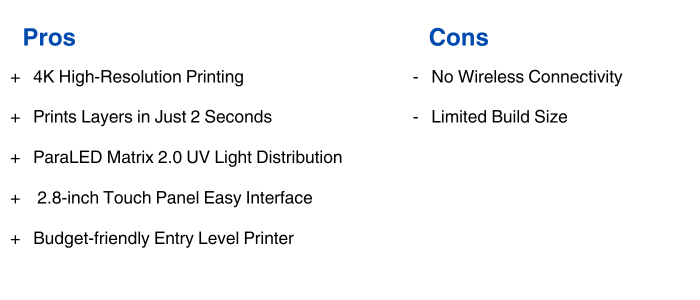

The Phrozen Sonic Mini 4K delivers powerful resin 3D printing with features designed to simplify the entire process. Its 4K monochrome LCD screen and fast printing speed help produce sharp and accurate prints quickly. With ParaLED Matrix 2.0 technology, it ensures even UV light distribution for consistent results. Its ability to work with various resins makes it suitable for many creative and professional applications.

The printer’s sturdy design, compact size, and user-friendly interface fit well in both personal and professional settings. From crafting miniature models and designing jewelry to creating dental prototypes and engineering parts, the Sonic Mini 4K supports a wide range of projects. Its thoughtful design keeps workflows smooth and efficient, helping creators stay focused on bringing their ideas to life.