Spectroplast SAM Full Review

Spectroplast is committed to delivering swift and unparalleled silicone solutions that empower customers to reach their objectives. With a mission centered on providing rapid and innovative manufacturing technologies, they aim to lead the transformation in the elastomers industry. Previously a company delivering 3D printed silicone solutions as a service, they launched their first commercially available silicone 3D printer, the Silicone Additive Manufacturing (SAM). Their patented technology enables the direct fabrication of 100% pure silicones without the need for molds. This advancement accelerates production speeds while enhancing precision and reliability. SAM is a valuable asset for industries ranging from medical technology to consumer goods. In this review, we’ll take a closer look at the Spectroplast SAM, exploring its features, performance, and how it aligns with Spectroplast’s dedication to sustainability and quality.

Design and Build Quality

The Spectroplast SAM is a silicone 3D printer designed to integrate smoothly into any professional environment. The SAM showcases Spectroplast’s unique Silicone Additive Manufacturing technology, enabling the direct printing of 100% pure silicones. The intuitive touchscreen interface simplifies the user experience by allowing easy navigation through settings and real-time monitoring of the printing process. The printer also includes an automatic calibration system that ensures minimal errors and print reliability. Manufactured in Schlieren, Switzerland, the SAM benefits from meticulous in-house production standards. They continuously optimize their production processes and manufacturing facility, which ensures them prudently managing their resources. Additionally, they consistently take measures to further improve their sustainability footprint.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Patented Silicone Additive Manufacturing (SAM) | Build Volume: 130 x 70 x 100 mm |

| High Precision Printing | XY Resolution: 75 x 75 microns Z Resolution: 100 microns |

| Reliable Z-Axis Accuracy | Dimensions 430 × 510 × 820 mm |

| User-Friendly Touchscreen Interface | Process: Vat photopolymerization |

| Automatic Calibration System | Dimensions 430 × 510 × 820 mm |

| Interchangeable Build Platform | Materials: Polymers, Elastomers, Silicone |

| Sustainable Manufacturing Practices | Weight: Approximately 80 kg |

The SAM features the patented SAM technology, allowing direct printing of pure silicones without molds. This ensures each print is precise and reliable. With an XY resolution of 75 x 75 microns and a Z resolution of 100 microns, the SAM delivers detailed and consistent results suitable for complex designs. The user-friendly touchscreen interface and automatic calibration make the printing process straightforward, reducing setup time and minimizing errors. Additionally, the interchangeable build platform offers flexibility for various silicone types, while the durable construction ensures long-term reliability. Manufactured in Schlieren, Switzerland, the SAM upholds high standards of quality and sustainability, making it a dependable choice for diverse industrial and medical applications.

Comparisons

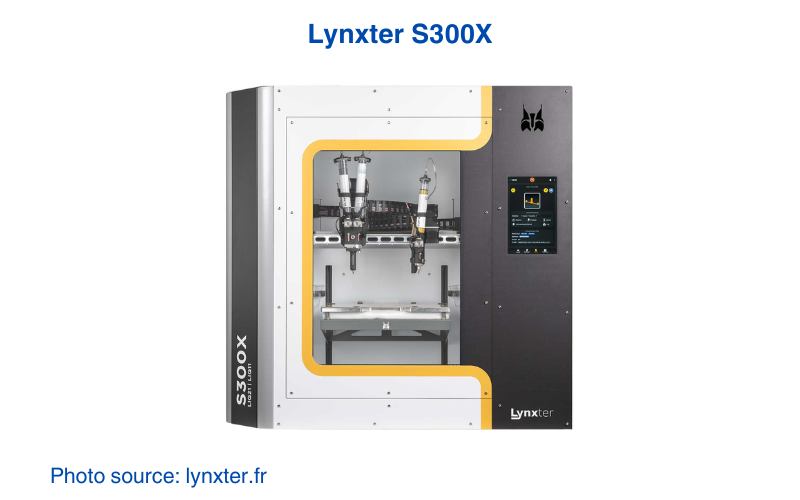

Spectroplast SAM vs. Lynxter S300X

The Spectroplast SAM and Lynxter S300X are both advanced silicone 3D printers designed for professional and industrial applications. However, each offers unique features that cater to different user needs.

Material Compatibility: The Spectroplast SAM specializes in processing 100% pure silicones, ensuring high chemical resistance and thermal stability. In contrast, the Lynxter S300X supports a broader range of materials, including various silicones and polyurethanes.

Build Volume: The Spectroplast SAM has a build volume of 130x70x100 mm, ideal for medium-sized projects and specialized silicone parts. On the other hand, the Lynxter S300X has a larger build volume of 300x250x200 mm, accommodating larger prints or multiple smaller parts simultaneously. This larger capacity makes the S300X better suited for high-volume production environments.

Extrusion System: The Spectroplast SAM utilizes a single extrusion system optimized for consistent silicone flow. Conversely, the Lynxter S300X features an Independent Dual Extrusion (IDEX) system with two toolheads, allowing for multi-material printing without contamination.

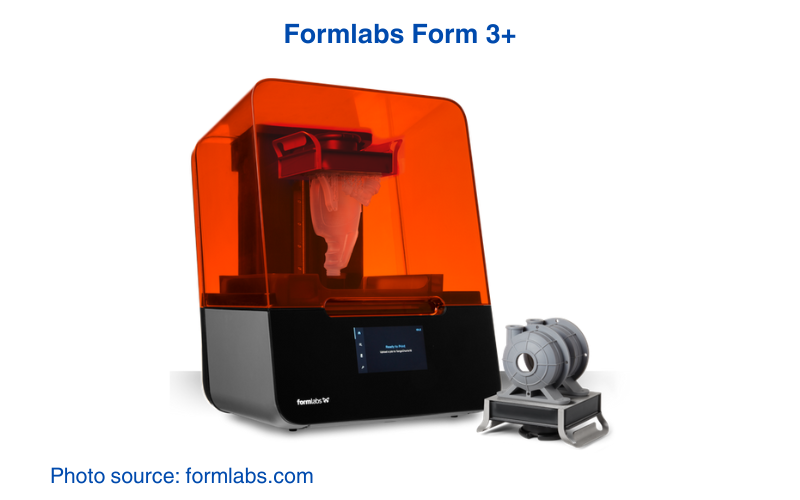

Spectroplast SAM vs. Formlabs Form 3+

While the Formlabs Form 3+ is primarily a resin-based printer, comparing it to the Spectroplast SAM highlights the SAM’s specialization in silicone printing.

Material Compatibility: The Form 3+ excels with resin-based materials, including the proprietary Silicone 40A Resin, which is a composite of silicone. However, the Spectroplast SAM processes 100% pure silicones, for superior material properties for applications requiring pure silicone components.

Printing Speed: The Spectroplast SAM provides efficient printing speeds tailored for silicone manufacturing, whereas the Form 3+ is optimized for high-detail resin prints. The SAM’s speed is advantageous for producing larger quantities of silicone parts quickly.

Design and Reliability: Both printers are designed for professional use, but the Spectroplast SAM is built specifically for silicone additive manufacturing with a focus on reliability and consistency in silicone prints. The Form 3+ is highly reliable for resin prints but does not match the SAM’s specialization in pure silicone processing.

Real World Applications

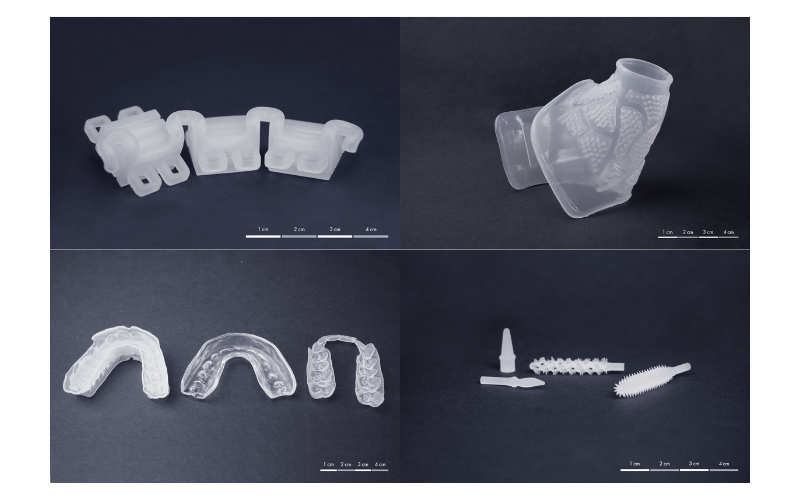

The Spectroplast SAM proves invaluable across various industries by delivering high-quality, customized silicone parts for companies that need them.

Industrial Solutions

In industrial settings, the SAM manufactures custom sealants, gaskets, and grommets with precise dimensions and excellent surface finishes. Additionally, the SAM creates buttons, keypads, and input solutions for Human-Machine Interfaces (HMI), ensuring consistent haptic feedback and durability. Sanitary solutions benefit from the SAM’s ability to produce unique, functional items that meet strict hygiene standards. The printer also excels in producing microparts for medical devices, household appliances, and electrical engineering, ensuring each small component performs reliably.

Healthcare and Medical

In the healthcare sector, the SAM enables the production of innovative cosmetic applicators like mascara brushes and lipstick tips, allowing for quick adaptation to market trends. Baby care products, including pacifiers, teats, and teething rings, are manufactured with high precision, ensuring safety and comfort. Female care products benefit from the SAM’s ability to create items tailored to specific needs, enhancing user satisfaction. Anatomical models produced by the SAM accurately mimic human tissue, aiding in education, surgical planning, and diagnostic simulations. Wearables and smart accessories are custom-fit for comfort and functionality, while patient-specific implants are designed and produced quickly, reducing lead times and costs for medical facilities

Custom Prosthetics

The SAM prints orthotic appliances precisely manufactured to enhance comfort and effectiveness, ensuring a perfect fit. Prosthetic limbs produced by the SAM combine functionality with a natural appearance, providing users with affordable and aesthetically pleasing options. Additionally, the SAM fabricates custom epitheses, such as toes, fingers, noses, and ears, with high accuracy, ensuring they match the patient’s anatomy.

Conclusion

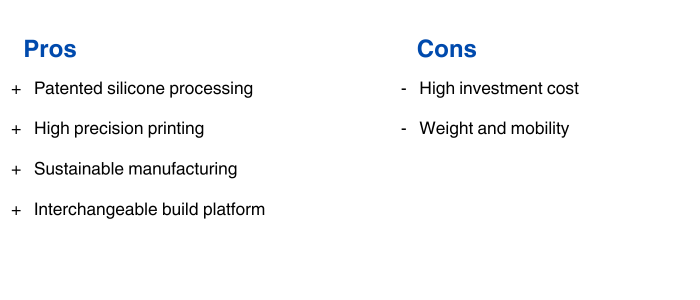

The Spectroplast SAM is a powerful tool for high-quality silicone 3D printing. Its patented Silicone Additive Manufacturing (SAM) technology enables the direct printing of 100% pure silicones without molds. This ensures precise and reliable prints for a wide range of industries such as healthcare, dental, prosthetics, and industrial applications.

With features like a high-resolution printing system, user-friendly touchscreen, and automatic calibration, the SAM offers both accuracy and ease of use. Its sturdy construction ensures long-term reliability, while its commitment to sustainable practices adds value to businesses seeking eco-friendly solutions. Though it has a smaller build volume and single extrusion system, the SAM excels in its specialty—producing precise, high-quality silicone parts. For industries requiring consistent, reliable silicone manufacturing, the Spectroplast SAM is a top choice worth considering.