Flashforge Creator 4-S Full Review

Since its founding in 2011, FlashForge has been a driving force in the 3D printing industry. The company started with a vision to make high-quality 3D printing accessible and reliable for everyone. Over the years, FlashForge has consistently delivered on this vision by creating printers that combine advanced technology with user-friendly designs. The Creator series is a standout in FlashForge’s lineup. The latest addition to the commercial-grade line, the Creator 4-S features advanced components like interchangeable extruders and a temperature-controlled chamber. It is made for complex engineering materials such as carbon fiber 3D printing, mass production, and other commercial applications. In this Flashforge Creator 4-S full review, we will see the full capabilities of this FDM 3D printer, along with comparing it to the other features in the Creator 4 line.

Design and Build Quality

Built for Professional Use

The FlashForge Creator 4-S is engineered with a focus on commercial-grade reliability and precision. Encased in a solid metal frame, the printer withstands the rigors of continuous operation. The fully enclosed build chamber maintains a consistent internal temperature, which is crucial for working with high-performance materials like carbon fiber composites and engineering plastics.

One of the key features of the Creator 4-S is its print bed. This heated, ultra-flat surface ensures minimal warping.It creates strong and dimensionally accurate parts, which is crucial for applications requiring tight tolerances. The use of linear rails in the motion system further enhances the printer’s precision, giving this model smooth and accurate movements that contribute to the overall quality of the prints.

Available in 3 Variations

The FlashForge Creator 4 is available in three variations based on the included extruders. The key difference between these versions lies in the specific hotends that come with the machine.

Extruder- F is designed for flexible filaments and dissolvable supports. While not included by default, this extruder is ideal for printing with filaments like TPU85A, TPE, TPB, and TPC. It features a 2.85mm filament diameter, reaches temperatures up to 265°C, and can print at speeds of 100mm/s.

Extruder-HT is included with the standard machine and is geared towards engineering filaments. It supports filaments such as PC, PA, PP, PETG, ASA, ABS, PLA, and more. This extruder operates at a maximum temperature of 320°C, uses 1.75mm filaments, and can achieve print speeds up to 200mm/s.

Extruder HS made for specialized printing such as carbon fiber and other composite materials. The extruder features a hardened steel nozzle that withstands the high wear and tear from abrasive materials. It supports filaments like PACF, PET-CF, PP-CF, PA-GF, and more, with a temperature ceiling of 360°C and a print speed of 150mm/s, built for high-strength, high-temperature applications.

Creator 4-S comes with (2) Extruder-HS and (2) Extruder-HT.

Creator 4-A comes with (2) Extruder-HT.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Interchangeable Independent Dual Extruder System (IIDEX) | Build Volume: 400 x 350 x 500 mm |

| Temperature-Controlled Printing Chamber | Maximum Print Speed: 200 mm/s |

| High-Precision Linear Rail System | Layer Height Range: 0.1mm to 0.4mm |

| Heated Print Bed | Nozzle Diameter Options: 0.4/0.6/0.8 mm |

| Advanced Material Compatibility | Max Extruder Temperature: 360°C (HS), 320°C (HT) |

| Intelligent Filament Management | Filament Compatibility: Carbon Fiber Composites, PLA, ABS, PA, PC, PETG, and more |

| Filament Run-Out and Power Failure Recovery | Maximum Bed Temperature: 120°C |

| FlashPrint Software | Power Consumption: 2320 W |

| Supported OS: Windows, Mac OS X, Linux | |

| Connectivity: Wi-Fi, Ethernet, USB |

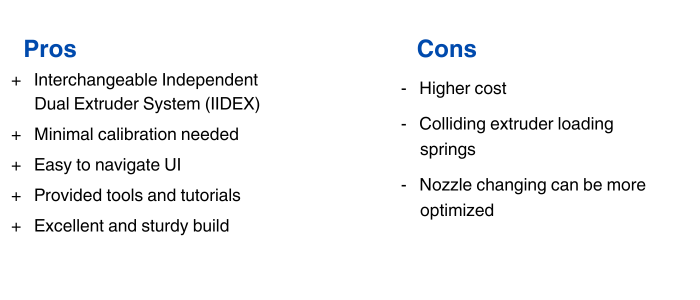

The FlashForge Creator 4-S is a powerful, commercial-grade machine designed for professionals. Its Interchangeable Independent Dual Extruder System (IIDEX) enables the printer to handle complex multi-material builds with ease. You can achieve high-quality prints, even when working with challenging materials like flexible filaments and carbon fiber composites.

Its temperature-controlled printing chamber maintains a consistent environment up to 65°C. This feature is critical for reducing thermal contraction, important for engineering-grade materials that require precise temperature management. The high-precision linear rail system ensures smoother movements and better accuracy. The heated, ultra-flat print ensures it can deliver dimensionally accurate parts. The Creator 4-S handles a broad spectrum of materials, including carbon fiber composites, ABS, PA, PC, PETG, and more, with its advanced extruder options. The intelligent filament management system automatically adjusts the printing temperature to match the material. Additionally, it has a filament run-out sensor and power failure recovery.

Comparisons

Creator 4-S vs. Creator 3 Pro

Comparing the Creator 4-S to the Creator 3 Pro, both models are geared toward professional use. But the Creator 4-S steps up with several key advancements:

Build Volume: The Creator 4-S has a larger build volume of 400 x 350 x 500 mm. Compared to the Creator 3 Pro’s 300 x 250 x 200 mm.

Extruder System: The Creator 3 Pro features a dual extruder setup that is reliable for standard dual-material prints. However, the Creator 4-S introduces the Interchangeable Independent Dual Extruder System (IIDEX), which has greater control over material handling. This system reduces material cross-contamination. The quality of multi-material prints is better.

Temperature-Controlled Chamber: The Creator 4-S features a temperature-controlled chamber. The Creator 3 Pro lacks this feature, making it less ideal for high-performance materials.

Creator 4-S vs. Creator 4-A

Another comparison within the FlashForge lineup is between the Creator 4-S and the Creator 4-A, both of which are part of the Creator 4 series but made for slightly different needs:

Extruder Options: The Creator 4-A comes equipped with two Extruder-HTs, designed for high-temperature materials up to 320°C. The Creator 4-S, however, includes both the Extruder-HS, which reaches up to 360°C, and the Extruder-HT. This gives 4-S a broader range of material compatibility, including more specialized filaments like carbon fiber composites.

Application Focus: The Creator 4-S, with its extruder options, is made to handle a broader range of materials, especially those involved in industries requiring advanced materials like aerospace or automotive. The Creator 4-A, while still highly capable, is more focused on standard engineering materials.

Material Flexibility: The Creator 4-S excels in providing flexibility for different material needs, with its interchangeable extruders and temperature-controlled chamber. The Creator 4-A is slightly more specialized, focusing on a narrower range of high-temperature materials. This might be sufficient for specific industrial applications but lacks the additional adaptability of the Creator 4-S.

Real World Applications

Advanced Manufacturing with Carbon Fiber

The FlashForge Creator 4-S is a leading choice for industrial applications that require the strength, durability, and lightweight properties of carbon fiber composites. Its capabilities are particularly valuable in sectors where these material characteristics are crucial. Here’s how the Creator 4-S is making a significant impact across various advanced manufacturing applications:

Aerospace and Automotive

In aerospace and automotive industries, weight reduction is key to performance and fuel efficiency. The Creator 4-S can be utilized to produce components such as lightweight brackets, support structures, and housings. These parts are made from carbon fiber composites. It provides exceptional strength while significantly reducing weight compared to traditional materials like metal. For instance, carbon fiber brackets can replace metal ones in aircraft interiors, having the same structural support at a fraction of the weigh. In automotive applications, carbon fiber engine mounts, drive shafts, and aerodynamic components are being printed to improve vehicle performance and efficiency.

Prototyping and Functional Testing

For companies involved in high-performance product development, the Creator 4-S allows for the creation of prototypes that are not just conceptual models but functional parts. Carbon fiber’s excellent strength-to-weight ratio enables the production of prototypes that can undergo rigorous testing in environments similar to those faced by final products. For example, in the development of drones, carbon fiber arms and frames can be 3D printed to test aerodynamics, load-bearing capacity, and crash resistance. These prototypes can be used in wind tunnel tests or in actual flight conditions, providing valuable data that informs the final design.

Tooling and Jigs

In manufacturing environments, the need for custom tooling, jigs, and fixtures is constant. The Creator 4-S can print these tools using carbon fiber, resulting in equipment that is both durable and lightweight. For instance, carbon fiber jigs used in the assembly of automotive parts can be custom-made to ensure exact alignment and fit. Additionally, carbon fiber molds for thermoforming plastics or composite layups can be quickly produced.

Consumer Electronics

In consumer electronics, durability and weight are critical factors. Strong, lightweight enclosures and structural components for products like drones, cameras, and portable electronic devices can be printed using the 4-S. For example, carbon fiber drone frames can be printed to withstand impacts while maintaining a low weight, which improves flight performance and battery life. Similarly, camera stabilizers and mounts made from carbon fiber provide the necessary rigidity and durability without adding excessive weight, making them ideal for professional use in the field.

Conclusion

The FlashForge Creator 4-S is a standout choice for those working in industries where carbon fiber 3D printing is essential. It’s built to handle tough materials, delivering strong and lightweight parts for complex projects. This 3D printer has the reliability and precision that is needed for aerospace components, automotive parts, or custom tools.

Its advanced extruder system and temperature-controlled chamber make it easy to work with carbon fiber, ensuring consistent results that hold up under stress. This printer is a solid option for professionals looking to push their 3D printing capabilities further. With the Creator 4-S, you can confidently take on complex projects, knowing your prints will be accurate, durable, and ready for real-world use.