Best Silicone 3D Printers

Silicone is a durable material known for its flexibility, heat resistance, and biocompatibility. Most of today’s silicone seals, joints, wearable technology, and robotic grippers are made using injection or compression molding, which requires a model, a mold, and then silicone injected into the mold. However, 3D printed silicone removes the model and mold steps entirely, printing the final part directly. This can save up to 90% in cost and time compared to traditional methods. Despite its benefits, 3D printing silicone presents challenges. Unlike thermoplastic filaments that become malleable when heated, silicone solidifies permanently and cannot be remelted. Additionally, silicones are highly resistant to UV light and cannot be cured in their pure form, requiring additives to make them sensitive to light or heat for 3D printing. This article will explore the best silicone 3D printers, discussing their strengths and features:

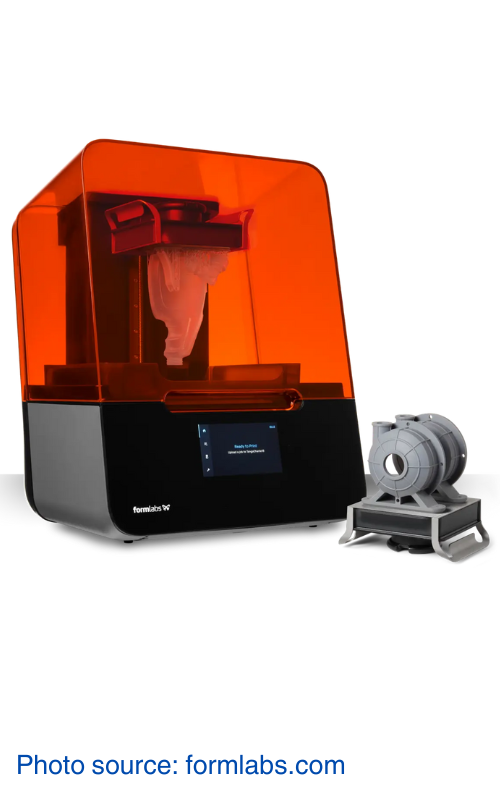

1. Formlabs Form 3+

Why it’s Top Notch:

- Patent-Pending Pure Silicone Technology

- Compatible Silicone Resin

- High Precision and Detail

- Hassle-Free Materials Management

The Formlabs Form 3+ is notable for its innovative approach to silicone 3D printing. Utilizing their patent-pending Pure Silicone Technology, this printer can produce fully silicone parts efficiently. The specially developed silicone resin works seamlessly with the Form 3+, ensuring users can achieve high-quality prints with exceptional precision and detail. This makes the Form 3+ ideal for applications requiring the unique properties of silicone, such as flexibility and durability, while maintaining the ease of use and reliability Formlabs is known for.

2. Lynxter S300X

Why it’s Top Notch:

- Industrial grade IDEX

- Multi-material printing without cross-contamination

- Customizable extrusion

- Handles High-Performance Silicone

- Modular Print Heads

- High-Resolution Printing

The Lynxter S300X is a go-to for those needing high-performance silicone prints. Its ability to handle specialized silicone ensures your parts are both durable and flexible. The modular print heads let you switch materials easily, making it super versatile. It has a large build volume of 300 x 250 x 200 mm with an advanced control system that guarantees precise temperature and material flow. Plus, with its high-resolution printing, you can expect detailed and precise outcomes, perfect for industrial applications.

Read the full review >>

3. Spectroplast SAM

Why it’s Top Notch:

- SAM Patented Technology

- High Precision and Accuracy

- Fast Printing Speed

- No mold and zero waste production

The Spectroplast SAM is dedicated to silicone printing, making it a top choice for producing high-quality silicone parts. Spectroplast operated as a print-on-demand service, but eventually launched their silicone 3D printer for commercial sale. This model has high precision and accuracy with around 0.1 mm accuracy. Spectroplast claims SAM prints 100% medical-grade ISO-certified silicones ensuring biocompatibility. In addition, Spectroplast states that SAM enables the creation of high-precision silicone products directly, eliminating the need for molds and generating zero waste.

Read the full review >>

To a flexible manufacturing future

Silicone 3D printing technology has come a long way, making it easier and faster to create flexible, durable parts without the need for traditional molding processes. While it does present some challenges, like the need for specific additives and specialized printers, the benefits are clear. You can save a ton of time and cost, especially for low-volume or custom parts. Plus, with the growing variety of printers and materials available, there are more options than ever to get high-quality silicone prints. Formlabs Form 3+, Lynxter S300X, Spectroplast SAM are all game changers in the silicone 3D printing and in the world of manufacturing.

Comments are closed.