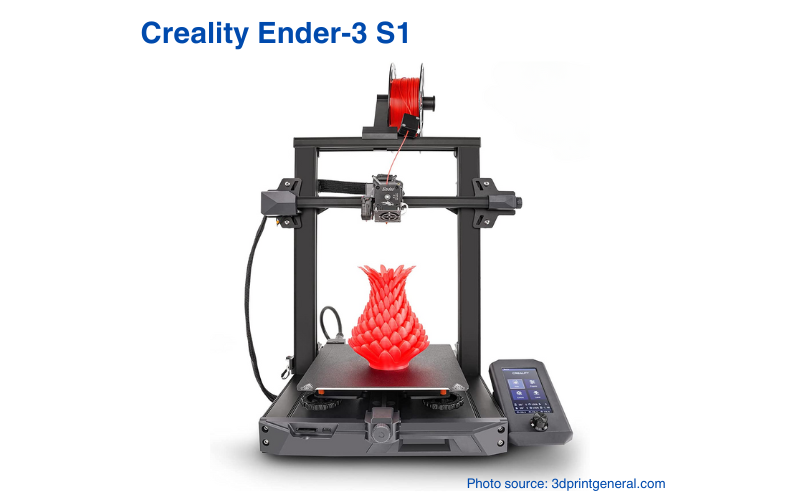

Creality Ender-3 S1 Full Review

Creality, a well-established name in the 3D printing industry, has consistently delivered reliable and affordable 3D printers since its inception in 2014. Known for their innovation and commitment to quality, Creality’s product line are both for beginners and experienced users alike. The Ender series, one of their most popular ranges, has garnered significant attention for its user-friendly design and impressive performance at a budget-friendly price. Since the launch of the original Ender-3, this series has seen several iterations, each building upon the strengths of its predecessors while incorporating new features. The Ender-3 S1 continues this tradition, with advanced capabilities while maintaining the accessibility that the Ender series is known for. In this Creality Ender-3 S1 full review, we will take a look at its features, design, printing capabilities, as well as compare it to its similar siblings in the Ender line.

Design and Build Quality

The Creality Ender 3 S1 includes several additional features that enhance its usability and performance. The filament runout sensor automatically pauses the print if the filament runs out or breaks. The power loss recovery feature ensures that the printer can resume from where it left off in case of a power interruption. The S1 also features a silent motherboard with TMC2208 drivers, which significantly reduces noise during operation. Quick assembly is another highlight, with the printer arriving partially assembled, allowing users to get started with minimal effort. Finally, the 4.3-inch color LCD screen makes for easy navigation and monitoring.

Improvements

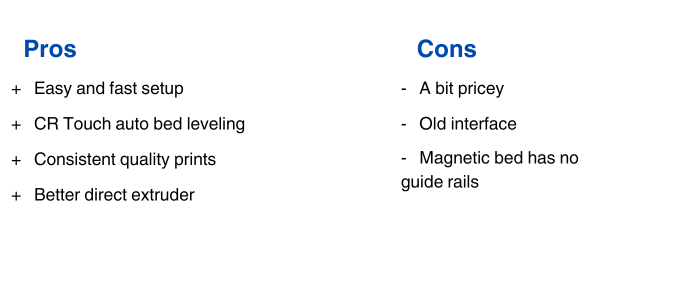

The Creality Ender 3 S1 introduces several notable upgrades over the Ender 3 V2. The addition of dual Z-axis lead screws enhances stability. This reduces the risk of layer shifts during printing, especially with taller models. The switch to a direct drive extruder makes for a better control over filament feeding. This change makes it easier to work with flexible materials like TPU. This is a significant improvement from the V2’s Bowden setup.

The S1 also features the CR Touch auto bed leveling system, which simplifies bed leveling by automatically adjusting the print surface—a big upgrade from the manual leveling required by the V2. Additionally, the power supply is now integrated beneath the build plate, giving the printer a cleaner look. The flexible magnetic build plate makes print removal easier, addressing a common challenge in earlier models. These enhancements make the Ender 3 S1 a more reliable and user-friendly printer.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Dual Z-Axis Lead Screws | Build Volume: 220 x 220 x 270 mm |

| Dual-Gear Direct Drive Extruder | Layer Resolution: 100-400 microns |

| Flexible Magnetic Build Plate | Nozzle Diameter: 0.4 mm (standard) |

| CR Touch Auto Bed Leveling | Max Nozzle Temperature: 260°C |

| Silent Motherboard with TMC2208 Drivers | Printing Accuracy: 0.1mm |

| Filament Runout Sensor | Printing Layer Thickness: 0.1 – 0.35mm |

| Power Loss Recovery | Filament Compatibility: PLA, TPU, PETG, ABS |

| 4.3-inch Color LCD Screen | Connectivity: SD Card, USB |

| Print Speed: Up to 160 mm/s (recommended 60-100 mm/s) | |

The Creality Ender 3 S1 has a a range of advanced features and impressive technical specifications. The build volume of 220 x 220 x 270 mm allows for the creation of moderately large models, while the layer resolution ranging from 100 to 400 microns ensures detailed prints. The direct drive extruder, combined with a standard 0.4 mm nozzle, delivers precise filament control, especially when working with flexible materials like Nylon. The S1’s nozzle can reach temperatures of up to 260°C. The printer’s TMC2208 silent drivers ensure quiet operation Connectivity options include an SD card slot and USB port, making it easy to transfer files. The 4.3-inch color LCD screen provides a user-friendly interface, rounding out the S1’s comprehensive feature set.

Comparison

Ender-3 S1 vs Ender-3 V2

The Ender-3 V2 is a well-regarded model in the Ender series, known for its ease of use and solid performance. Here’s how it compares to the Ender 3 S1:

Build Volume: The build volume remains similar between the two models, with both having 220 x 220 x 270 mm.

Extruder Type: The S1 features a direct drive extruder. This extruder has better control over flexible filaments compared to the V2’s Bowden extruder.

Bed Leveling: The Ender-3 V2 requires manual bed leveling, while the Ender-3 S1 has CR Touch auto bed leveling system.

Price: The Ender-3 V2 is more affordable, making it a good choice for those new to 3D printing. However, the additional features of the S1 justify its higher price for users looking for more advanced capabilities.

Ender-3 S1 Ender-5 Pro

The Ender-5 Pro is another popular model from Creality, known for its stability and build quality. Here’s how it stacks up against the Ender 3 S1:

Build Volume: The Ender-5 Pro has a larger build volume of 220 x 220 x 300 mm, which is slightly bigger than the S1’s 220 x 220 x 270 mm.

Frame Design: TheEnder-5 Pro features a box-like frame. The Ender-3 S1, while stable, uses the more traditional open-frame design of the Ender series.

Bed Leveling: The Ender-5 Pro requires manual bed leveling, while the Ender-3 S1 comes equipped with the CR Touch auto bed leveling system.

Price: The Ender-5 Pro is priced higher due to its larger build volume and stability, but the S1 offers a more compact design with advanced features at a slightly lower price.

Real World Applications

The Ender-3 S1 can be used in a variety of niche industries and creative fields where its combination of precision, reliability, and affordability is useful. Here are some specific applications where the Ender 3 S1 is advantageous:

Custom Jewelry Design

Independent jewelers and small-scale manufacturers can utilize the Ender-3 S1 to create detailed molds and prototypes for custom jewelry pieces. The direct drive extruder and fine layer resolution allow for intricate designs that can be cast in precious metals.

Cosplay and Prop Making

Cosplayers and prop makers can rely on the Ender-3 S1 to bring their creative visions to life. The printer’s ability to handle flexible filaments and large build volume makes it ideal for producing costume components, accessories, and detailed props.

Automotive Customization

In the automotive industry, particularly among hobbyists and custom car builders, the Ender-3 S1 can be used to create custom parts and accessories. Pieces like dashboard components and custom badges and emblems can be printed using this model. This application is especially popular among those who participate in car shows and need bespoke modifications.

Board Game and Miniature Production

The growing community of independent board game designers and miniatures are using the Ender-3 S1 to create detailed game pieces, custom tiles, and intricate miniatures. The printer’s precision and ability to work with different materials make it perfect for producing small, detailed items that enhance the gaming experience. It also allows creators to experiment with new designs before committing to mass production.

Conclusion

The Creality Ender-3 S1 has a number of features that make it a standout model in the Ender series. With features like dual Z-axis lead screws, a direct drive extruder, and the CR Touch auto bed leveling system, Creality has created a printer that’s both reliable and easy to use. What really sets the Ender-3 S1 apart is how well it performs in real-world scenarios. You can design custom jewelry, craft cosplay props, or build intricate scale models. It’s also finding its way into niche industries like automotive customization and board game production, proving that this printer can handle a wide range of creative tasks. If you’re looking for a 3D printer that has advanced features without breaking the bank, the Creality Ender-3 S1 is a fantastic choice.