EOS M 400 Full Review

Since its founding in 1989, EOS has taken innovative steps in advancing additive manufacturing technology. They have developed an extensive portfolio that includes 3D printers, materials, and process parameters. Their statement of commitment to sustainability through Responsible Manufacturing is seen in them delivering high-quality production while minimizing environmental impact. In 3D printing, aluminum is a material known for its strength, durability, and lightweight properties. EOS uses their laser-powder interaction expertise to make aluminum 3D printing possible. The EOS M 400 is an example of their innovation. Designed for industrial applications, the M 400 has a large build volume and precise engineering, making it ideal for producing complex metal components with impressive detail. In this EOS M 400 full review, we will take a look at its features, design and how it can be used in additive manufacturing.

Design and Build Quality

EOS built the M 400 for industrial-scale production, featuring a large build volume of 400 x 400 x 400 mm. This size is perfect for producing big, detailed metal parts. The machine weighs approximately 4,635 kg (10,218 lbs) and measures 4181 x 1613 x 2355 mm, making it well-suited for heavy-duty manufacturing environments.

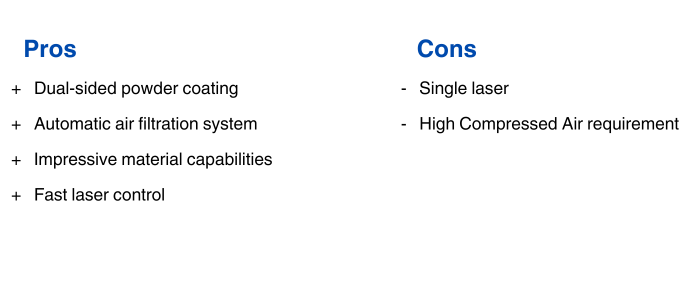

The design reduces downtime and makes operation smoother. It coats both sides with powder material. The circulating air filtering system automatically cleans itself, extending filter life and reducing frequent maintenance. These features make it great for large-scale production, where reliability and consistent performance are important.

The Technology of EOS M 400

The EOS M 400 uses a 1000-watt Yb-fiber laser, enabling it to produce high-quality metal parts quickly. Its precision optics, including an F-theta lens and high-speed scanner, allow for a scan speed of up to 7.0 m/s. This helps boost productivity with faster build rates and thicker layers.

The machine runs on EOS’s software suite, which includes EOS BUILD/BUILD+, EOS DATA INSIGHTS, and EOS SYSTEM SUITE. These tools give users control over the process, from tracking build data to optimizing performance. The focus diameter of around 90 µm ensures fine detail, which is essential when creating parts that need accuracy and high-performance.

The EOS M 400 supports a wide variety of materials, from light metals to super alloys, making it adaptable for different manufacturing needs. The technology meets the challenges of producing high-quality parts at scale.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Industrial-size Build Volume | Build Volume: 400 x 400 x 400 mm |

| Powerful 1000-Watt Yb-Fiber Laser | Laser Type: Yb-fiber laser, 1 x 1000 W |

| Precision Optics | Scan Speed: Up to 7.0 m/s (23.0 ft/s) |

| Dual-Sided Powder Coating | Focus Diameter: Approx. 90 µm (0.00354 in) |

| Circulating Air Filtering System | Compressed Air Supply: 7 Bar; 20 m³/h (102 psi; 706 ft³/h) |

| Easy Maintenance Design | Machine Dimensions: 4181 x 1613 x 2355 mm |

| EOS Software Suite | Weight: Approx. 4635 kg (10,218 lbs) |

| Metal Frame and Enclosure | Recommended Installation Space: Min. 6500 x 6000 x 3300 mm |

| Proprietary Materials: EOS Aluminium AlF357, EOS Aluminium AlSi10Mg, EOS Aluminium Al2139 AM, EOS CopperAlloy CuNi30, EOS CopperAlloy CuCrZr, EOS MaragingSteel MS1, EOS NickelAlloy IN718, EOS StainlessSteel 316L, EOS Titanium Ti64, EOS Titanium Ti64ELI |

The EOS M 400 is packed with features that prioritize productivity and precision. With a large build volume and a 1000-watt laser, it’s capable of handling large-scale projects with ease. Its precision optics enable fast scanning speeds, while the dual-sided powder coating system reduces downtime. The air filtering system ensures smooth operation and longer filter life, making maintenance easier. It supports a broad range of materials, from light metals to super alloys, and is backed by EOS’s comprehensive software suite for process optimization.

Comparisons

M 400 vs M 290

Here’s how the EOS M 400 compares to the EOS M 290, another well-regarded model in the EOS lineup. While both machines target industrial applications, they serve different production needs based on scale and part size.

Build Volume: The M 400 has a larger build volume of 400 x 400 x 400 mm. It is more suitable for larger parts. The M 290 has a smaller build volume of 250 x 250 x 325 mm, ideal for compact parts.

Laser Power: The M 400 features a 1000-watt laser, which allows for faster build rates and thicker layers. The M 290’s 400-watt laser focuses on delivering more detailed work on smaller parts compared to the M 400.

Production Scale: The M 400 suits serial manufacturing and high-volume production, while manufacturers typically use the M 290 for smaller-scale, high-precision applications.

M 400 vs M 300-4

The M 400 and the M 300-4 serve different production environments despite both being powerful industrial machines. Particularly in terms of speed and laser configuration:

Laser Configuration: The M 400 uses a single 1000-watt laser. The M 300-4 is equipped with four lasers. This multi-laser setup allows the M 300-4 to achieve faster build speeds, which is ideal for higher-volume production.

Build Volume: Both printers have similar build volumes. However, the M 300-4’s multiple lasers are more efficient for large batch production. The M 400’s single-laser system suits industries that need thicker layers and sturdy part production.

Speed vs. Efficiency: The M 300-4 is the better choice for faster output across multiple parts simultaneously. Meanwhile, the M 400’s 1000-watt laser is for a solid balance between speed and quality for large-scale parts.

Real World Applications

EOS designed the M 400 for industrial-scale manufacturing and engineered it for high-performance applications. Here are some specific examples of how industries use this machine:

Aerospace

The aerospace industry can use the EOS M 400 to produce complex metal components. Examples are turbine blades, fuel nozzles, and engine parts. The ability to work with high-strength alloys like Titanium Ti64 and Nickel Alloy IN718 makes it perfect for creating lightweight, durable parts that can withstand extreme conditions. These parts often replace traditionally cast or machined components, offering improved performance and weight savings.

Automotive

The automotive industry can utilize the EOS M 400 to produce custom engine components, heat exchangers, and transmission parts. Its large build volume and capability to handle materials like Aluminum AlSi10Mg and Stainless Steel 316L, allow manufacturers to create strong, lightweight parts that improve vehicle efficiency. The high-speed laser technology ensures the timely production of large batches of parts.

Oil and Gas

The oil and gas sector can apply the EOS M 400 to create critical components like valves, pumps, and drilling equipment. These parts, often made from materials like Maraging Steel MS1 and CopperAlloy CuCrZr, must endure high pressure and corrosive environments. The M 400’s ability to produce robust, complex parts reduces the need for multi-part assemblies, improving reliability in harsh conditions and reducing maintenance costs.

Tooling and Molds

The M 400 is also ideal for producing large, precise tools and molds used in various manufacturing processes. Tooling made from materials like Maraging Steel MS1 offers the strength and durability needed for high-volume production. This machine’s high build rates and accuracy help manufacturers reduce lead times for custom molds, making it a valuable asset in sectors like injection molding and die casting.

Conclusion

The EOS M 400 is an industrial-grade aluminum 3D printer built for industrial manufacturing. Its large build volume and powerful 1000-watt laser make it ideal for producing complex metal parts quickly and accurately. Supporting a wide range of materials, including aluminum, titanium, and super alloys, the M 400 serves industries like aerospace, automotive, and oil and gas.

With features designed to reduce downtime, such as the dual-sided powder coating and automatic air filtration system, the M 400 ensures efficient production. The integrated EOS software suite provides users with full control over the process, delivering consistent, high-quality results. For businesses needing a reliable, scalable solution for large metal parts, the EOS M 400 offers both productivity and precision.