Best Aluminum 3D Printers

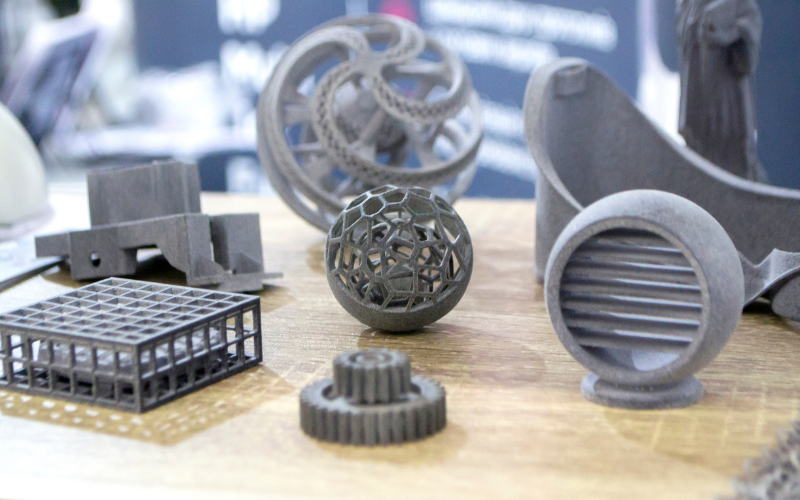

Aluminum 3D printing is a cutting-edge manufacturing process that involves creating three-dimensional objects from aluminum powder. This process is primarily achieved through techniques such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), where a high-powered laser selectively melts and fuses aluminum powder layer by layer to build a solid object. Aluminum is favored in FDM 3D printing due to its strength, lightweight nature, and excellent thermal properties. These characteristics make it ideal for producing intricate and high-performance parts for industries like aerospace, automotive, and robotics. Aluminum 3D printing enables the creation of complex geometries and custom designs that are often unachievable with traditional manufacturing methods, leading to innovative solutions and improved performance in various applications. This article explores the top 3D printers that excel in printing with aluminum directly out of the box, highlighting their strengths and features. Let’s begin:

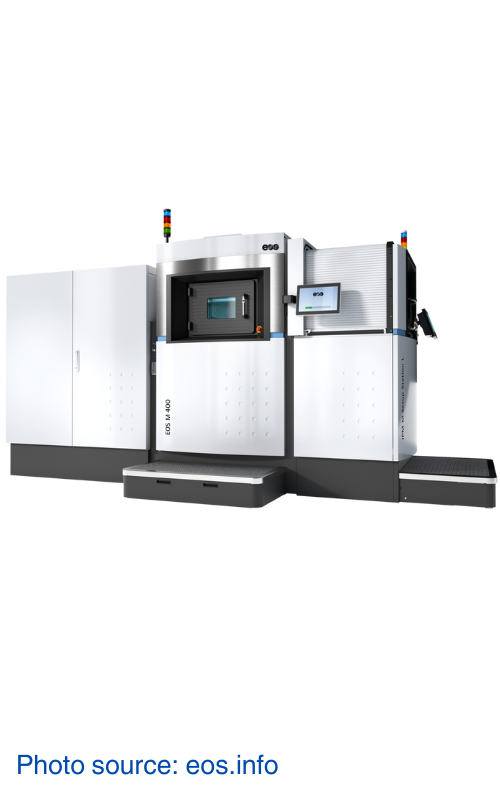

1. EOS M 400

Why it’s Top Notch:

- 1000-Watt Yb-Fiber Laser

- 400 x 400 x 400 mm Build Volume

- Broad Material Portfolio

- Automatic Coating System

- Circulating Air Filtering System

- User-Friendly Software: EOSPRINT 2 and EOSCONNECT

The EOS M 400 features a 1000-watt Yb-fiber laser that boosts productivity by enabling higher build rates and thicker layers. With a build volume of 400 x 400 x 400 mm, it can handle large projects or multiple smaller parts efficiently. The system supports a wide range of materials, including aluminum alloys like AlSi10Mg, known for its strength and thermal properties. Designed for ease of use, it includes features such as a coating system that minimizes downtime and an air filtering system that extends service life. The EOS M 400 combines powerful performance with user-friendly operation, making it a top choice for professionals in aerospace, automotive, and other high-tech industries.

2. 3D Systems ProX DMP 320

Why it’s Top Notch:

- High Precision and Throughput

- Versatile Material Options

- Exchangeable Print Modules

- 275 x 275 x 420 mm Build Volume

- Centralized Maintenance Management

- Detailed Process Monitoring

The 3D Systems ProX DMP 320 is designed with high precision and throughput capabilities to make it ideal for producing complex, chemically-pure metal parts. It supports a versatile range of materials, including titanium, stainless steel, and nickel super alloys, which are essential for industrial applications. The ProX DMP 320 features exchangeable print modules that allow for rapid material changes and efficient powder recycling, enhancing productivity. Its centralized maintenance management system and reduced argon gas consumption contribute to lower operating costs. Additionally, the ProX DMP 320 includes advanced process monitoring systems that provide real-time quality checks and control.

Read the full review >>

3. Desktop Metal Studio System 2

Why it’s Top Notch:

- Office-Friendly Metal 3D Printing

- Two-Step Process

- Separable Supports Technology

- 300°C Max Temperature

- Integrated Software

The Desktop Metal Studio System 2 is ideal for producing high-quality metal parts in office environments. Its simplified two-step process combines printing and sintering. It removes the step for solvent debinding. The Separable Supports technology further enhances ease of use by allowing finished parts to be removed without additional tools or post-processing. The Studio System 2 supports a range of metals, including stainless steel and copper. The system’s user-friendly design is complemented by Desktop Metal’s Fabricate software, which streamlines the preparation of print jobs and offers remote monitoring capabilities.

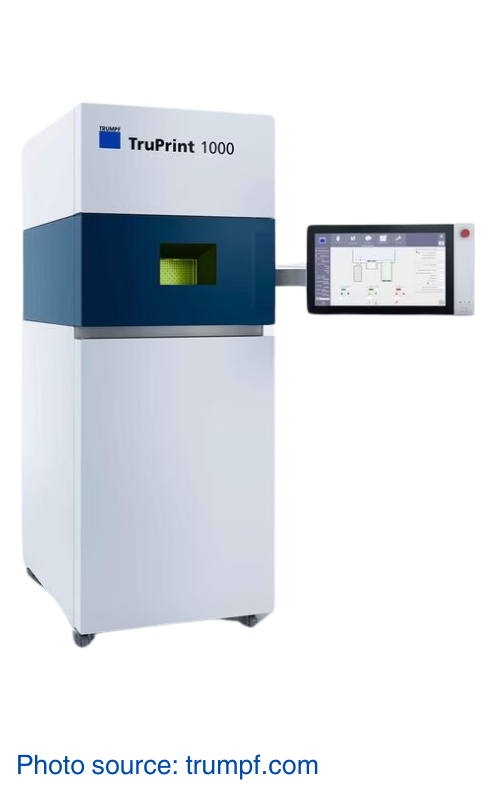

4. Trumpf TruPrint 1000

Why it’s Top Notch:

- Dual 200-Watt TRUMPF Fiber Lasers

- Adjustable Spot Diameter

- Ergonomic Powder Handling

- 275 x 275 x 420 mm Build Volume

- Advanced Monitoring Systems

- Automated Substrate Plate Change

The Trumpf TruPrint 1000 has dual 200-watt TRUMPF fiber lasers that can scan the entire build volume simultaneously, increasing productivity significantly. The adjustable spot diameter allows users to switch between 55 µm for the best surface quality and 80 µm for higher productivity, catering to different material requirements. It has ergonomic powder handling, with an inert powder cycle using a glove box and interchangeable cylinders to ensure safe and efficient material management. Additionally, the automated substrate plate change capability enables extended machine runtimes without needing constant operator supervision, making it suitable for continuous production environments.

Metals and Industries

When selecting an aluminum 3D printer, you have to consider factors such as build volume, laser power and precision, material compatibility, ease of use, and advanced monitoring and automation capabilities. These aspects determine the printer’s ability to handle specific industrial applications, ensure high-quality outputs, and streamline production processes. The EOS M 400 has a powerful 1000-watt laser and large build volume for extensive projects requiring high precision. The 3D Systems ProX DMP 320 is highly versatile with a range of material options and high throughput, suitable for complex metal parts. The Desktop Metal Studio System 2 is ideal for office environments by having a simplified two-step process and high-quality output needed for complex designs in aerospace and medical fields. Finally, the Trumpf TruPrint 1000 has a dual laser system and ergonomic powder handling, ensuring continuous high-quality production. Each model is ideal for industrial applications specifically using aluminum as material.