Nexa3D NXE400 Pro Review

Nexa3D is driven by a passionate team dedicated to reshaping the additive manufacturing industry through sustainable practices. They create ultra-fast polymer 3D printers designed to help businesses of all sizes boost productivity while reducing environmental impact. Their technology is engineered to break past traditional printing limits, making large-scale manufacturing faster and more efficient. Nexa3D’s patented technologies, like Lubricant Sublayer Photo-curing (LSPc) and Quantum Laser Sintering (QLS), redefine printing speeds while delivering consistent output. Their Digital Twin Printing (DTP) software fine-tunes material performance for better results. Sustainability is at the core of their mission. By reducing waste, lowering energy consumption, and collaborating with reforestation initiatives, Nexa3D works toward a greener future. In this Nexa3D NXE400 Pro review, we’ll examine how they leverage their groundbreaking technology to set new benchmarks in resin 3D printing.

Design and Build Quality

The Nexa3D NXE400 Pro is built with durability and efficiency in mind. Its industrial-grade construction supports long-term use, while its modular components simplify maintenance and future upgrades. Measuring 28 x 28 x 66 inches when uncrated, it fits well in professional workspaces while still offering a substantial build volume for large-scale projects. At 350 lbs uncrated, the printer stays stable during fast printing cycles. Its enclosed design helps maintain consistent printing conditions, reducing the chances of environmental interference. Nexa3D’s proprietary NexaX software complements the hardware with features like auto-orientation, nesting, and remote monitoring, streamlining print management for increased productivity. The NXE400 Pro strikes a balance between industrial-grade construction and efficient design, making it a practical choice for businesses looking to scale up their production capabilities.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 7K Resolution | Build Volume: 275 x 155 x 400 mm |

| Industrial-grade Build | Max Resolution: 7K (6480 x 3600) |

| Large Build Volume 10.8 x 6.1 x 15.7 inches | Pixel Size: 46 µm (0.0018 in) |

| LSPc Technology | Wavelength: 405 nm |

| Open Material Platform | Vertical Speed: Up to 24 cm/hour |

| Next-Gen Software | Layer Thickness: 25-200 μm |

| Post-Processing Integration | Electrical Requirements: 100-120 VAC (NA) / 210-230 VAC (EU) |

| Operating Environment: 20–25˚C with less than 70% humidity | |

| Dimensions: 28 x 28 x 66 inches uncrated (710 x 710 x 1675 mm) | |

| Net Weight: 350 lbs (160 kg) |

The Nexa3D NXE400 Pro pushes the boundaries of resin 3D printing with cutting-edge features designed for speed, accuracy, and efficiency. Its patented Lubricant Sublayer Photo-curing (LSPc) technology accelerates production, printing up to 6.5 times faster than other printers in its class. With a large 10.8 x 6.1 x 15.7-inch build volume, it handles bigger projects while maintaining high-resolution output at 7K (6480 x 3600 pixels). The open-material platform supports a variety of engineering-grade resins, offering flexibility for demanding industrial applications.

Advanced post-processing tools like xWash and xCure simplify the workflow, enhancing part quality while reducing processing time. The integrated NexaX software automates tasks such as model orientation, nesting, and real-time print monitoring, making production management more efficient. The NXE400 Pro’s modular design also supports easy maintenance and future upgrades, extending its service life.

Comparisons

NXE400 Pro vs. Carbon M3

The Nexa3D NXE400 Pro and Carbon M3 target industrial production, with distinct features aimed at different manufacturing necessities.

- Build Volume: The NXE400 Pro has a larger build volume of 275 x 155 x 400 mm, supporting bigger projects and higher part throughput. In comparison, the Carbon M3 has a smaller build area of 189 x 118 x 326 mm, making it better suited for medium-sized components.

- Printing Technology: The NXE400 Pro uses Lubricant Sublayer Photo-curing (LSPc) technology, enabling fast and uniform printing. The Carbon M3 features Digital Light Synthesis™ (DLS), known for its high-quality surface finishes and production-grade parts.

- Material Compatibility: The NXE400 Pro supports an open-material platform, enabling compatibility with engineering-grade resins like xPEEK and xABS. The Carbon M3 uses a closed ecosystem, requiring proprietary resins developed by Carbon.

- Post-Processing Integration: The NXE400 Pro integrates with Nexa3D’s xWash and xCure systems, simplifying post-processing while enhancing part quality. Carbon M3 works with the Smart Part Washer for efficient post-processing but lacks direct integration.

NXE400 Pro vs. Stratasys Origin One

The NXE400 Pro and Stratasys Origin One both excel in industrial resin 3D printing, with different priorities in speed and detail.

- Build Volume: The NXE400 Pro offers a 275 x 155 x 400 mm build volume, ideal for large-scale production. The Origin One provides a smaller 192 x 108 x 370 mm build area, catering to detailed and moderately sized parts.

- Printing Technology: The NXE400 Pro features LSPc technology for high-speed, continuous printing. In contrast, the Origin One uses Programmable PhotoPolymerization (P3) technology, designed for producing highly detailed and complex parts.

- Material Compatibility: The NXE400 Pro supports a wide range of materials through its open platform, allowing businesses to source resins from multiple suppliers. The Origin One relies on certified materials from Stratasys and its partners, limiting third-party compatibility.

- Post-Processing Workflow: The NXE400 Pro pairs with xWash and xCure for streamlined post-processing. The Origin One requires external third-party post-processing equipment, adding extra steps to the workflow.

Real World Applications

The Nexa3D NXE400 Pro is built for industrial production, supporting a wide range of applications across different industries. Its large build volume, advanced printing technology, and open-material platform make it a powerful tool for businesses looking to scale their production capabilities. Here are several key applications with specific examples:

- Functional Prototyping: In aerospace, engineers need lightweight, high-strength components for satellites. The NXE400 Pro’s ability to print with engineering-grade resins like xPEEK ensures parts can withstand extreme temperatures and mechanical stress. With its 7K resolution, the printer produces parts with smooth surfaces, reducing post-processing requirements and enabling faster fit testing and design iterations.

- Medical Device Manufacturing: Medical device manufacturers require accurate, patient-specific implants. Using the NXE400 Pro, healthcare providers can produce custom orthopedic implants tailored to individual patients. Its ability to print bio-compatible resins ensures compliance with medical-grade standards, while the large build volume supports batch production, reducing unit costs.

- Industrial Tooling and Fixtures: Factories rely on custom jigs and fixtures to streamline assembly line operations. The NXE400 Pro can produce these tools on demand using tough, impact-resistant resins like xABS. The printer’s high-speed output reduces downtime, while its consistent build quality ensures precision-fit fixtures that improve operational efficiency.

- Consumer Product Prototyping: Consumer electronics companies can use the NXE400 Pro to create custom housings for devices such as headphones and smart gadgets. The printer’s open-material platform supports ABS-like resins for high-quality, durable enclosures. With its large build volume, manufacturers can print multiple product shells simultaneously, speeding up product development cycles.

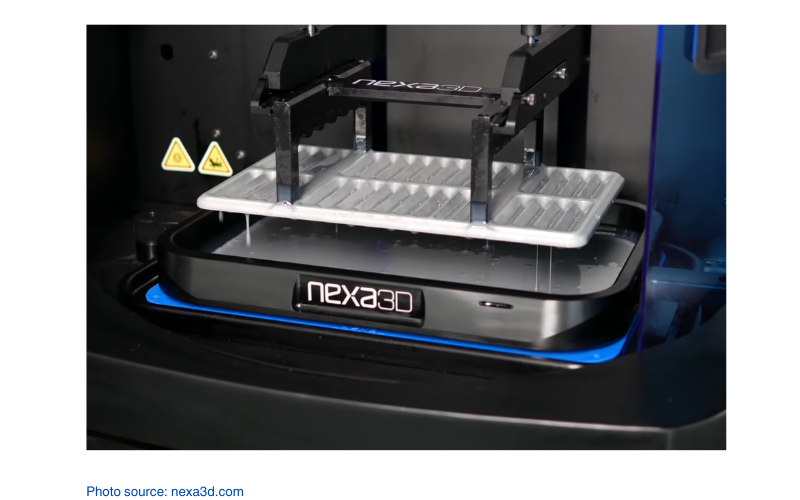

- Dental and Orthodontics: Dental labs can produce clear aligners using specialized resins on the NXE400 Pro. The printer’s accuracy and smooth surface finish reduce manual polishing steps. Its large build area supports batch production, helping labs handle large-scale orders efficiently while maintaining high-quality standards.

Conclusion

The Nexa3D NXE400 Pro redefines resin 3D printing with unmatched speed, large build capacity, and material flexibility. Its patented LSPc technology accelerates production by up to 6.5 times compared to traditional printers, transforming industrial manufacturing workflows.

With a build area of 275 x 155 x 400 mm and a 7K resolution, the NXE400 Pro supports large-scale projects while delivering consistently high-quality results. Its open-material platform supports engineering-grade resins like xPEEK and xABS, making it suitable for demanding industrial applications. Post-processing becomes easier with integrated xWash and xCure systems, streamlining the process and delivering production-ready parts faster. From automotive components and custom medical devices to industrial tools and consumer products, the NXE400 Pro improves production efficiency and reduces operational downtime.