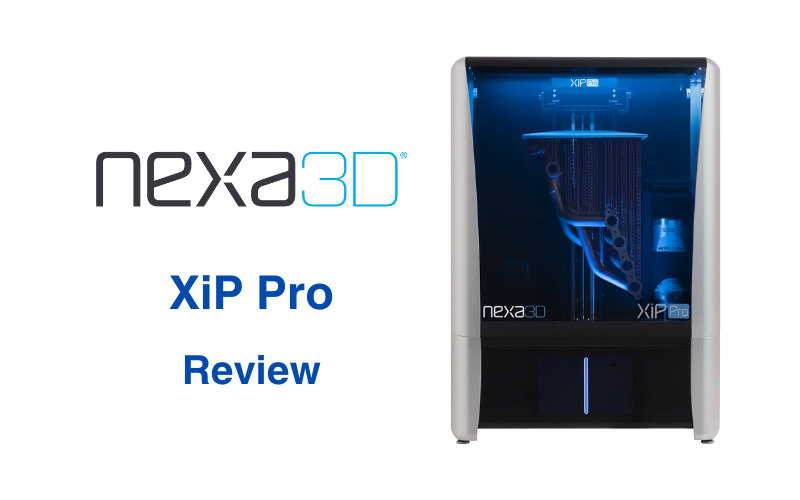

Nexa3D XiP Pro Review

Nexa3D is redefining the way we think about 3D printing with cutting-edge technology and a strong sustainability commitment. The company specializes in high-speed polymer 3D printers that boost productivity while keeping operational costs low. By developing advanced technologies like Lubricant Sublayer Photocuring (LSPc) and Quantum Laser Sintering (QLS), Nexa3D has reshaped what’s possible in industrial-grade 3D printing. Resin 3D printers have become popular because of their ability to produce smooth, professional-looking parts. They excel in creating everything from functional prototypes to production components, making them a favorite in industries like manufacturing, healthcare, and design. Their ability to capture complex shapes and fine features puts them in a league of their own. In this review, we’ll take a closer look at one of Nexa3D’s flagship models — the Nexa3D XiP Pro. We’ll take a look at its features and how it’s transforming resin-based 3D printing for professionals and businesses.

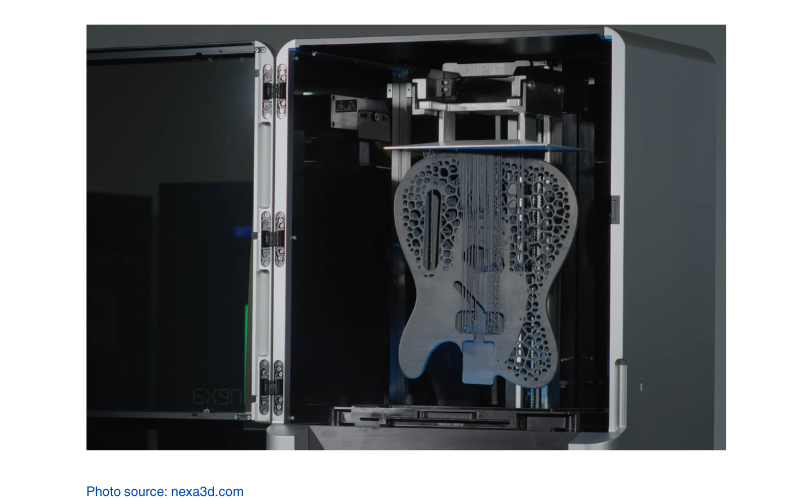

Design and Build Quality

The Nexa3D XiP Pro is built with industrial-grade durability in mind. Its solid billet aluminum unibody frame delivers unmatched strength and stability, ensuring consistent performance even during intensive printing sessions. The robust frame reduces vibrations and keeps the printer steady, supporting high-precision printing with exceptional results.

Its modular and upgradable design reflects Nexa3D’s forward-thinking approach. Measuring 622 x 447 x 895 mm (24.5 x 17.6 x 35.25 in), it packs industrial-level capabilities into a compact form that fits seamlessly into professional workspaces. Up front, a 10-inch high-resolution LCD touchscreen has an intuitive interface, simplifying printer control and status monitoring. The clean, professional finish underscores the XiP Pro’s purpose-built design, crafted for high performance in demanding industrial environments. Every feature has been thoughtfully engineered to maximize efficiency, reliability, and ease of use.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| 7K LCD Screen | Build Volume: 195 x 115 x 210 mm (4.8L capacity) |

| Ultra-Fast Print Speed | Build Capacity: 19.5 liters |

| Advanced LSPc Technology | LCD Resolution: 7K (6480 x 3600) |

| Closed-Loop Z-Stage | Pixel Size: 46 µm |

| Smart Resin Management | Print Resolution: 25 µm – 200 µm |

| Modular and Upgradable | Product Dimensions: 622 x 447 x 895 mm |

| Industrial Build Quality | Enclosure: Solid billet aluminum frame |

| Intuitive Touchscreen Interface | Interface: 10-inch high-resolution LCD touchscreen |

| Automated Post-Processing | Software: NexaX Pro |

| System Type: Open-platform | |

| Supported Materials: Over 30 validated resins |

The Nexa3D XiP Pro pushes the boundaries of resin 3D printing with industry-leading performance and cutting-edge technology. It features a 7K monochrome LCD screen with a resolution of 6480×3600 pixels, producing highly detailed prints with exceptional clarity. Its advanced Lubricant Sublayer Photocuring (LSPc) process enables ultra-fast printing speeds of up to 24 vertical centimeters per hour while maintaining top-tier print quality. The system’s closed-loop z-stage with auto-homing and debris detection refines accuracy and minimizes print failures.

The XiP Pro is designed for efficiency and reliability, offering smart resin management through its advanced sensor suite, which monitors environmental conditions and optimizes print settings in real time. The intuitive 10-inch LCD touchscreen simplifies printer operation, while its modular construction supports future upgrades. With an open-material platform, the printer supports over 30 validated resins, including engineering-grade and high-heat-resistant materials.

Comparisons

XiP Pro vs. Carbon® M3

The Nexa3D XiP Pro and Carbon M3 are designed for industrial resin 3D printing. These machines are built for businesses with high production demands. Here’s how they compare across essential performance areas:

- Build Volume and Throughput: The XiP Pro leads with its 19.5-liter build volume, producing more parts per print cycle than the Carbon M3. This larger capacity enables businesses to scale production faster and reduce equipment investment. The Carbon M3, with its smaller build area, is better suited for mid-size production runs or specialized parts.

- Speed and Efficiency: The XiP Pro delivers up to 24 vertical cm/h, completing large batches in under two hours. In contrast, the Carbon M3 achieves competitive speeds but falls short when handling large-scale, continuous production jobs.

- Operational Flexibility: With its open-material platform, the XiP Pro supports a wide range of engineering and functional resins. The Carbon M3 uses a closed system that limits material choices, requiring businesses to depend on Carbon’s proprietary resin offerings.

XiP Pro vs. Stratasys® Origin One

Both the XiP Pro and Stratasys Origin One are high-performance industrial resin 3D printers. Here’s how they compare in critical production features:

- Print Reliability: The XiP Pro features closed-loop z-stage control, auto-homing, and debris detection. This reduces print failures and improves consistency. The Origin One relies on user monitoring and manual adjustments for similar performance stability.

- Customization and Scalability: The XiP Pro’s modular design allows future upgrades and hardware expansions, helping businesses adapt to evolving production needs. The Origin One offers fewer customization options, making it less future-proof for rapidly growing production lines.

- Production Workflow Integration: The XiP Pro integrates with automated post-processing units like xWASH and xCURE, streamlining the entire production workflow from print to finished part. The Origin One, while capable, may require additional third-party systems for similar automation, increasing operational complexity.

Real-World Applications

The Nexa3D XiP Pro’s advanced printing capabilities extend across a variety of industries. It streamlines production workflows and reduces manufacturing timelines. Here are some key applications with real-world examples:

1. Automotive Manufacturing: Custom Parts and Prototypes

Automotive companies often require custom parts for testing and low-volume production. The XiP Pro can quickly produce dashboard panels, engine covers, and air intake components using engineering-grade resins like xABS or heat-resistant xPEEK. A manufacturer developing a new vehicle could prototype a custom air filter housing, test its fit and performance, and iterate on the design within days instead of weeks.

2. Dental and Medical Devices: Surgical Guides and Dental Models

In healthcare, speed and accuracy are essential for patient care. Dental labs can use the XiP Pro to print orthodontic models, surgical guides, and implant prototypes with validated dental resins. For example, a dental lab could produce a series of custom aligners overnight, reducing patient wait times and enabling same-day fittings.

3. Consumer Electronics: Product Housings and Functional Parts

The XiP Pro supports the production of electronics enclosures and functional components with materials like xPP for impact resistance or xCERAMIC for heat tolerance. A tech startup could prototype a smart thermostat housing with precise button cutouts and test the fit of its internal components before moving to mass production.

4. Aerospace Components: High-Performance Prototyping

The aerospace industry demands lightweight, high-strength components. Using high-temperature and heat-resistant resins like xPEEK, aerospace engineers can print prototypes of airflow ducts, control panels, and interior components. A drone manufacturer could print custom drone frames, test various designs, and move directly to short-run production without costly tooling.

5. Manufacturing and Tooling: End-Use Parts and Custom Fixtures

Manufacturing facilities often need custom jigs, fixtures, and tooling. The XiP Pro can produce durable tools that support production lines, reducing downtime. For example, a factory assembling electronic circuit boards could print a custom holding fixture overnight, ensuring continuous operation while waiting for permanent tooling to be machined.

Conclusion

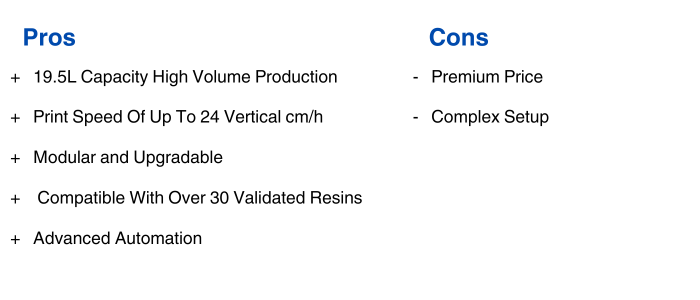

The Nexa3D XiP Pro redefines what’s possible in industrial resin 3D printing. Its impressive 19.5-liter build capacity and blazing print speed of up to 24 vertical cm/h make it a true production powerhouse. The 7K monochrome LCD screen delivers exceptional print quality with consistent results across the entire build platform. Its open-material platform supports over 30 validated resins, accommodating everything from high-temperature and engineering-grade materials to flexible and dental resins. The advanced features like smart resin management, closed-loop z-stage control, and automated post-processing integration streamline the entire workflow from design to final product.

For industries that manufacture automotive parts, medical devices, aerospace components or custom jewelry, the XiP Pro empowers businesses to accelerate product development while reducing production timelines. Its modular, upgradeable design ensures long-term productivity, positioning it as an essential tool for industrial manufacturers aiming to stay ahead in a fast-paced production environment.