TRUMPF TruPrint 1000 Full Review

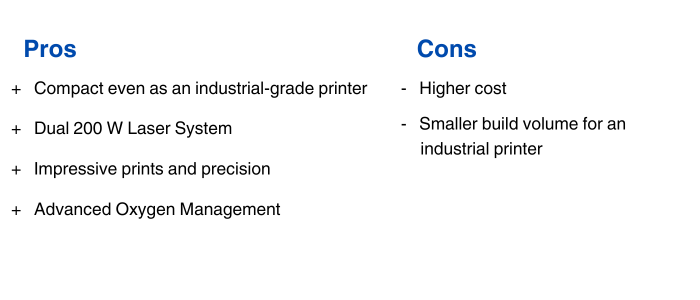

TRUMPF is a global leader in manufacturing technologies, with their innovative solutions in machine tools and industrial lasers. Founded in Germany, the company is a pioneer in the development of cutting-edge tools that shape industries worldwide. TRUMPF works across various sectors, helping companies enhance their production processes. One such technology is their TruPrint 3D printer line designed for additive manufacturing with metals like aluminum. The TRUMPF TruPrint 1000 is a machine made for small-scale production, focusing on quality. Because of its precision and reliability, this model efficiently produces highly detailed aluminum parts. Its user-friendly design and impressive output make it a valuable tool in various industries, from aerospace to medical technology. In this TRUMPF TruPrint 1000 full review, we will explore its features, capabilities, compare it to its siblings, and how it can be used in different industries.

Design and Build Quality

The TruPrint 1000 is designed to be compact and efficient for industries like dental, medical, and research. Its small size can fit easily through standard doors and into spaces like labs and universities. With its dimensions of 1445 x 730 x 1680 mm and a weight of 650 kg (including powder), it fits well in tight spaces while reliably delivering metal 3D printing.

Ease of use is important for the design of the TruPrint 1000. It features a user-friendly touchscreen and a helpful Setup Wizard, so users can set up quickly. The contactless powder handling system, equipped with a glove box and interchangeable cylinders, helps keep operations safe. The machine also has fast cylinder changes, reducing downtime and increasing overall productivity.

The Technology of TRUMPF TruPrint 1000

The TruPrint 1000 is packed with advanced technology for metal 3D printing. One of its key features is the full-field multilaser system, which uses two 200 W TRUMPF fiber lasers. These lasers work together to scan the entire build area, boosting production speed by up to 80% compared to single-laser machines. This makes it perfect for handling multiple orders quickly and efficiently.

Another highlight is the advanced gas flow system, which keeps the build chamber in ideal condition for high-quality parts with smooth surfaces and precise details. It’s especially useful when working with materials like titanium, where keeping oxygen levels low (down to 100 ppm) is critical. TruPrint 1000 features Power Bed Monitoring, which uses an integrated camera to track the build process layer by layer. This keeps everything on track and allows quick identification and resolution of any issues.

Key Features and Specifications

| Key Features | Specifications |

|---|---|

| Full-field Multilaser System | Build Volume: Ø 98.5 x H 100 mm |

| Compact Design | Build Rate: 2-18 cm³/h |

| Adjustable Laser Spot Diameter (55/80 µm) | Max Laser Power: 200 W |

| Inert Powder Handling with Glove Box | Layer Thickness: 10-50 μm |

| Integrated Power Bed Monitoring | Scan Speed: Up to 3 m/s |

| Multiplate Option for Extended Runtimes | O2 Concentration: Down to 100 ppm |

| Office-friendly | Shielding Gas: Nitrogen, Argon |

| Preform Option for Dental Applications | Dimensions: 1445 x 730 x 1680 mm |

| Motorized Optics | Weight: 650 kg (with powder) |

| TruTops Print Software for Easy Setup | |

| Quick Cylinder Replacement |

The TruPrint 1000 has a full-field multilaser system that makes production faster by using two 200 W TRUMPF fiber lasers to scan the entire build volume simultaneously. Its compact design fits easily into labs and research spaces. Inert powder handling ensures safe operation, particularly with reactive metals like titanium. The integrated Power Bed Monitoring system tracks the build process in real-time.

Designed for efficiency, the TruPrint 1000 has features like a multiplate option, allowing for longer machine runtimes without operator intervention. The motorized optics system makes switching between laser spot sizes quick and easy For dental applications, the Preform option reduces costs by focusing on the patient-specific portion of the work. Additionally, TruTops Print software simplifies setup and operation, while the quick cylinder replacement keeps production moving smoothly.

Performance and Output Quality

The TruPrint 1000 focuses on delivering fast, consistent, and high-quality 3D prints. Its dual 200 W lasers work together to speed up the process. The improved gas flow system keeps the build chamber stable, helping ensure each print comes out with smooth surfaces and precise details, even on complex designs.

This machine doesn’t just focus on speed—it gives you control over every part of the process. With Power Bed Monitoring, you can watch the layers as they’re built and catch any issues early on. This keeps things running smoothly and ensures reliable, high-quality results, which is especially important in industries like dental, medical, and research, where precision matters most.

Ability to Handle Aluminum and Other Metals

Working with aluminum and other metals can be challenging, but the TruPrint 1000 handles it with ease. Aluminum’s reflective nature can be tough for 3D printers, but the TruPrint 1000’s adjustable laser spot diameter helps tackle this issue. By switching between a 55 µm and 80 µm beam diameter, the machine can adjust the energy needed to work with aluminum and other reflective metals like copper.

Beyond aluminum, the TruPrint 1000 works well with a wide range of metals, including stainless steel, titanium, and cobalt-chrome. These materials are critical in industries like aerospace and medical, where strength and precision are essential. The machine’s ability to maintain a low oxygen environment (down to 100 ppm) ensures titanium parts come out with high-quality results.

Comparisons

TruPrint 1000 vs. TruPrint 2000

When comparing the TruPrint 1000 to the TruPrint 2000, both machines are made for precision metal printing, but they meet different needs:

Build Volume: The TruPrint 1000 offers a smaller build area (Ø 98.5 x H 100 mm), whereas the TruPrint 2000 provides a larger volume, making it better for producing larger parts or handling more parts simultaneously.

Laser System: Both models have dual 200 W lasers, but the TruPrint 2000 includes more advanced process monitoring features, adding greater precision for industrial production.

Production Workflow: The TruPrint 2000’s larger build size and enhanced monitoring make it better suited for industrial environments with high-volume, continuous production needs.

TruPrint 1000 vs. TruPrint 3000

Both the TruPrint 1000 and TruPrint 3000 are built for industrial metal 3D printing, but they address different production scales:

Build Volume: The TruPrint 1000 is ideal for smaller parts with its compact build volume. While the TruPrint 3000 has a much larger capacity, making it perfect for producing large components or multiple parts in a single run.

Material Handling: The TruPrint 3000 has more advanced powder management systems, including automated recycling, which enhances production efficiency. This feature is not available in the TruPrint 1000.

Production Scale: The TruPrint 3000 is designed for industrial-scale production, handling large projects efficiently. Whereas the TruPrint 1000 is better suited for smaller, high-precision applications.

Real World Applications

The TRUMPF TruPrint 1000 is an industrial-grade 3D printer, well-suited for high-precision metal printing. Below are examples of how the TruPrint 1000 is used in various industries:

Dental

In the dental industry, precision is critical. The TruPrint 1000 is used to produce custom dental plates with enhanced performance and surface quality. Dental labs can create multiple dental prosthetics in a single run, increasing production efficiency and reducing post-processing times.

Medical

In medical settings, the TruPrint 1000 is ideal for producing custom titanium implants. Its ability to maintain low oxygen levels in the chamber (down to 100 ppm) ensures high-density, smooth-surfaced parts. Hospitals and medical manufacturers can quickly produce patient-specific implants like bone plates and joint replacements with excellent mechanical properties. This significantly reduces production time and provides life-saving solutions faster.

Aviation and Aerospace

In the aerospace industry, engineers use the TruPrint 1000 to produce lightweight, high-strength components.Examples are titanium brackets and structural supports. These parts withstand extreme stress and meet the industry’s strict safety standards. By utilizing the machine’s dual-laser system, companies can rapidly prototype and produce parts. This reduces lead times and improving overall performance of the aircraft.

Tool and Mold-making

The TruPrint 1000 is capable of producing highly detailed molds and tools from metals such as aluminum and stainless steel. For example, manufacturers can print custom jigs and fixtures that must endure repeated use in harsh environments. The machine’s ability to handle intricate designs ensures that every tool is accurate and ready for high-performance applications.

Conclusion

The TRUMPF TruPrint 1000 is a powerful tool for industries that need reliable, high-quality metal 3D printing. It works exceptionally well across fields like dental, medical, aerospace, and tool-making. Its dual-laser system speeds up production, while its advanced powder handling keeps parts consistent and precise.The TruPrint 1000 has a compact size, user-friendly interface, and ability to produce complex, durable parts.

In dental labs, the TruPrint 1000 speeds up the production of prosthetics, delivering detailed, smooth finishes. For medical manufacturers, it allows for quick creation of custom implants while maintaining the strict quality needed for patient care. Aerospace companies benefit from its ability to produce lightweight, durable components like brackets, improving overall aircraft performance. Overall, the TruPrint 1000 is a top-tier aluminum 3D printer for industries that need metal 3D printing.